Thin-wall weak-rigidity part machining and fixing method and temperature control machining platform

A processing platform, weak rigid technology, applied in machine tool parts, metal processing equipment, machine operation and other directions, to avoid stress rebound, high-precision adjustment, fast connection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

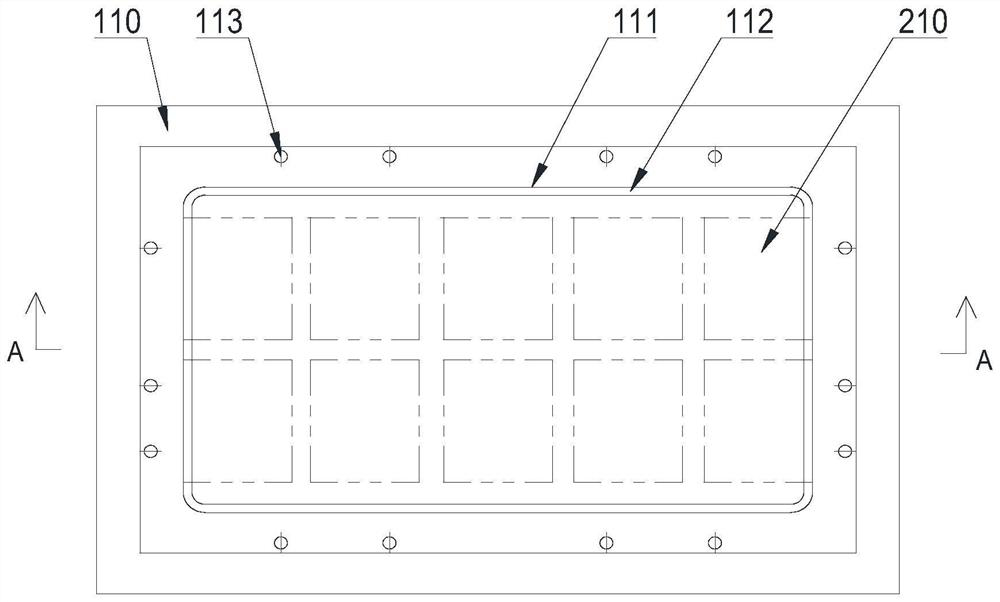

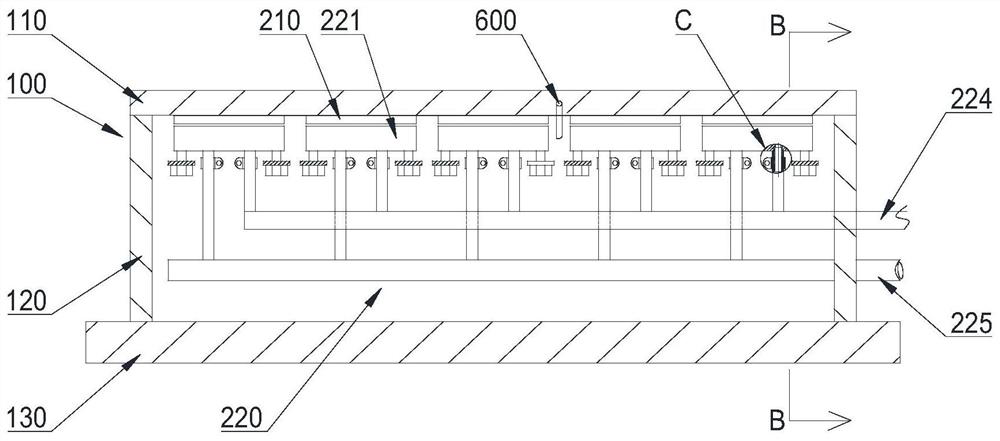

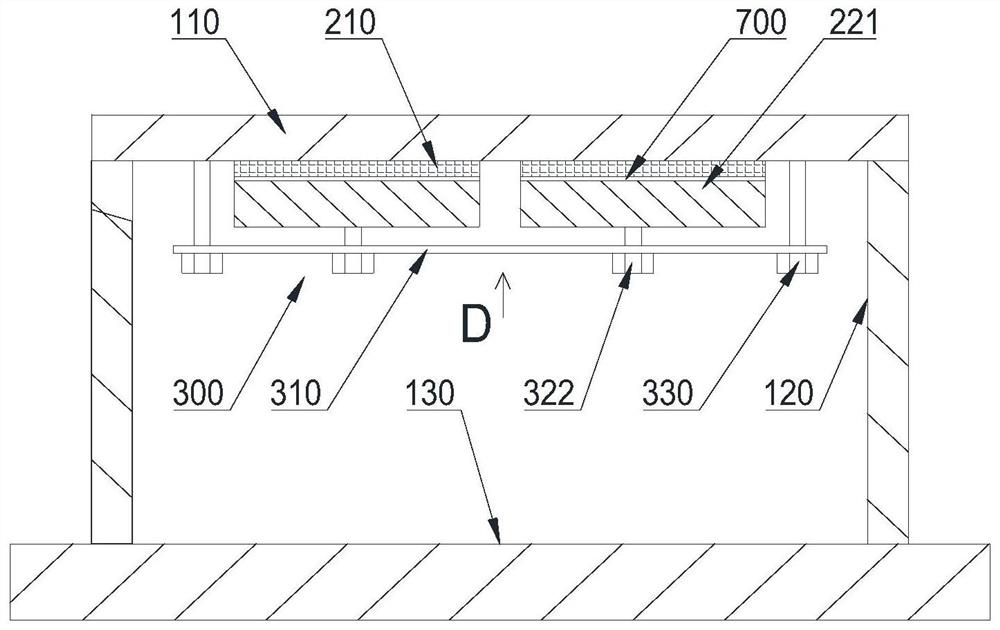

[0043] Such as Figure 1-8 As shown, the temperature-controlled processing platform for thin-walled and weakly rigid parts provided in this embodiment includes a platform frame 100 , a cooling and heating assembly and a fixing assembly 300 . in:

[0044] The platform frame 100 is composed of a panel 110 , a middle frame 120 and a bottom plate 130 , and the top and bottom of the middle frame 120 are respectively fixedly connected with the panel 110 and the bottom plate 130 by bolts.

[0045] A cooling and heating assembly is fixedly installed below the panel 110 , and the latter includes a cooling sheet group and a heat sink 220 .

[0046] The refrigerating sheet group includes a plurality of semiconductor refrigerating sheets 210 arranged in an array and installed on the lower surface of the panel 110 . The Peltier effect occurs when the semiconductor refrigeration sheet is connected with direct current. By controlling the direction of the current in and out, it can produce co...

Embodiment 2

[0054] Such as Figures 13 to 14 As shown, in this embodiment, on the basis of Embodiment 1, an adapter plate 400 is added to accommodate parts that are difficult to be fixed stably. The adapter plate 400 has an upper surface that is concavo-convex matched (complementary) to the fixed surface of the processed part 800 , so as to match and install the processed part 800 with an uneven fixed surface. The adapter plate 400 can be configured with positioning pins 420 according to needs, so as to facilitate the positioning of the processed part 800 , and the adapter plate 400 itself is fixed on the panel 110 through the pressure plate 410 and bolts. In order to improve the thermal conductivity, a thermal conductive material layer 700 (a graphite pad is used in this embodiment, not shown in the figure) is provided between the adapter plate 400 and the panel 110 to improve the heat transfer effect.

Embodiment 3

[0056] The processed part 800 is an installation base plate 130 for aerospace communication, and the material is aluminum alloy. The flatness of the part 800 and the depth of the middle step (1.5±0.06) require high accuracy. If ordinary pressing blocks or backing plates are used for clamping, the parts are easily deformed, which cannot meet the processing accuracy requirements. If a vacuum suction cup is used for clamping, springback deformation is prone to occur after processing. Even if two large planes are repeatedly turned over and clamped to process two large planes, the flatness requirements cannot be effectively guaranteed, and the efficiency is low and the pass rate is very low. For example, the general-purpose two-component adhesive clamping method at room temperature cannot meet the needs of industrial production due to the influence of many factors such as long curing time of the adhesive, difficulty in controlling the uniformity of the adhesive, and large damage to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com