A kind of monodisperse superparamagnetic carboxyl silicon magnetic bead and preparation method thereof

A technology of superparamagnetic and carboxyl silicon, which is applied in the fields of magnetism of organic materials/organic magnetic materials, manufacturing of inductors/transformers/magnets, and electrical components, etc. Problems such as poor dispersion of carboxyl magnetic bead emulsion, to achieve the effect of high specific binding rate, good dispersion and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present embodiment provides a kind of monodisperse superparamagnetic carboxy silicon magnetic bead, and its preparation method comprises:

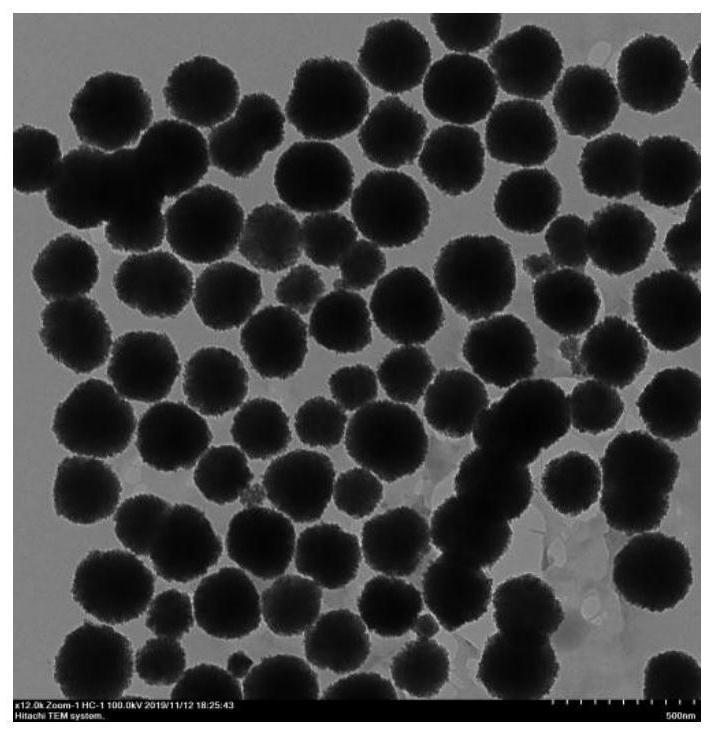

[0029] (1) Fe 3 o 4 Preparation of nanoclusters: weigh 1.08g FeCl 3 ·6H 2 0 to a three-necked flask, add 40ml of ethylene glycol to fully dissolve, and when heated to 60°C, add 0.108g of polyacrylic acid (PAA) and 9g of NaAc simultaneously at a stirring rate of 500r / min, and stir to completely dissolve the solid. The reaction solution was transferred to a reaction kettle, and reacted at 200° C. for 12 hours. After the reaction is completed, use a magnetic stand for auxiliary magnetic separation, alternately wash with deionized water and ethanol several times, remove the residual components and by-products of the reaction, dry in a drying oven, and collect monodisperse superparamagnetic Fe 3 o 4 Nanoclusters, whose transmission electron microscope pictures are shown in figure 1 shown.

[0030] (2) Fe 3 o 4 @SiO 2 Prepar...

Embodiment 2

[0034] The present embodiment provides a kind of monodisperse superparamagnetic carboxy silicon magnetic bead, and its preparation method comprises:

[0035] (1) Fe 3 o 4 Preparation of nanoclusters: weigh 1.08g FeCl 3 ·6H 2 O to a three-necked flask, add 40ml of diethylene glycol to fully dissolve, and when heated to 60°C, add 0.108g of PAA and 9g of NaAc simultaneously at a stirring rate of 500r / min, and stir to completely dissolve the solid. The reaction solution was transferred to a reaction kettle, and reacted at 250° C. for 12 hours. After the reaction is completed, use a magnetic stand for auxiliary magnetic separation, alternately wash with deionized water and ethanol several times, remove the residual components and by-products of the reaction, dry in a drying oven, and collect monodisperse superparamagnetic Fe 3 o 4 nanoclusters.

[0036] (2) Fe 3 o 4 @SiO 2 Preparation: Weigh 0.1g of Fe obtained in step (1) 3 o 4 Nanoclusters, 60ml ethanol and 20ml deioni...

Embodiment 3

[0039] The present embodiment provides a kind of monodisperse superparamagnetic carboxy silicon magnetic bead, and its preparation method comprises:

[0040] (1) Fe 3 o 4 Preparation of nanoclusters: weigh 1.08g FeCl 3 ·6H 2 O to a three-necked flask, add 40ml of ethylene glycol to fully dissolve, and when heated to 60°C, add 0.108g of PAA and 9g of NaAc simultaneously at a stirring rate of 500r / min, and stir to completely dissolve the solid. The reaction solution was transferred to a reaction kettle, and reacted at 200° C. for 12 hours. After the reaction is completed, use a magnetic stand for auxiliary magnetic separation, alternately wash with deionized water and ethanol several times, remove the residual components and by-products of the reaction, dry in a drying oven, and collect monodisperse superparamagnetic Fe 3 o 4 nanoclusters.

[0041] (2) Fe 3 o 4 @SiO 2 Preparation: Weigh 0.1g of Fe obtained in step (1) 3 o 4 Nanoclusters, 60ml ethanol and 20ml deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com