Method for producing chlorinated fatty acid methyl ester by resource utilization of byproduct hydrochloric acid

The technology of chlorinated fatty acid methyl ester and fatty acid methyl ester is applied in the field of resource utilization of by-product hydrochloric acid to prepare environmental plasticizers, and can solve the problems of various impurities in by-product hydrochloric acid and by-product hydrochloric acid, catalysts easily affected by impurities, and additional downstream products. It can reduce the purification process of hydrochloric acid, achieve high product quality stability and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

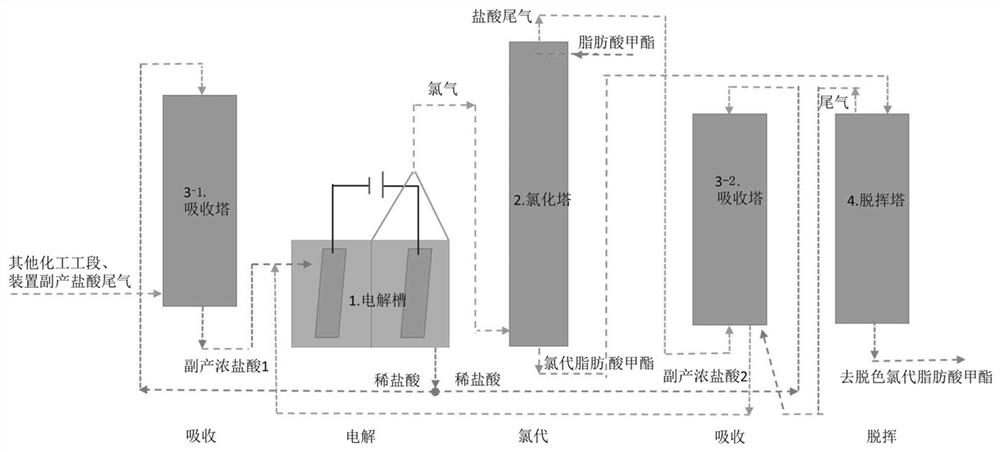

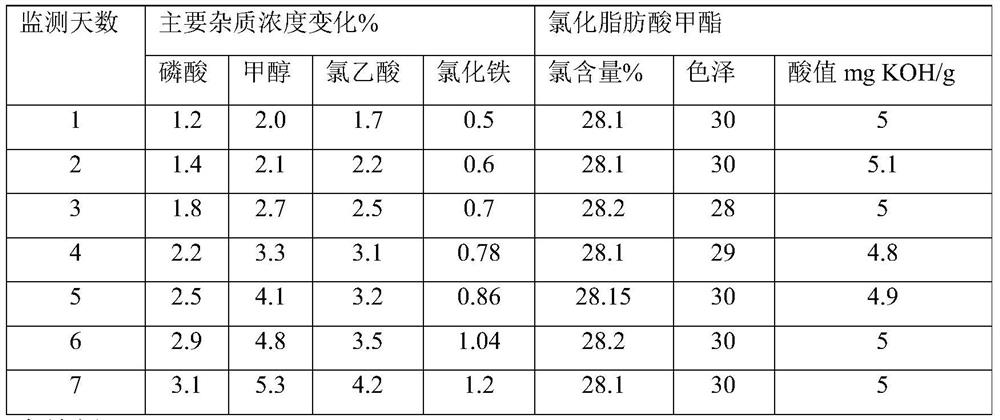

[0030] In this embodiment, chlorine gas is produced by electrolytic by-product hydrochloric acid, and chlorine gas and fatty acid methyl ester are reacted in the tower to obtain chlorinated fatty acid methyl ester, see figure 1 . Its processing steps and specific conditions are as follows:

[0031] Hydrochloric acid by-products: HCl content 30%, phosphoric acid content 2.5%, methanol content 4.7%, chloroacetic acid content 1.6%, monochloromethane content 0.15%, dimethyl phosphite content 0.12%, silicic acid content The content of dimethyldichlorosilane hydrolyzate (D3, D4) is 0.01%, the content of ferric chloride is 0.35%, and the content of potassium sulfate is 0.005%.

[0032] 1) Add the above hydrochloric acid by-products into the electrolytic cell, adjust the voltage of the electrolytic cell to 2.7V, and send the generated mixed gas (mainly 90% of chlorine gas, about 10% of HCl and water vapor) to the condenser to condense to 5°C (exist figure 1 Omit in), remove the moi...

Embodiment 2

[0039] In this embodiment, chlorine gas is produced by the electrolysis of hydrochloric acid by-product in Example 1, and by optimizing the electrolysis voltage parameters, the temperature of the electrolytic cell and the concentration of hydrochloric acid fed into the electrolytic cell, the output of chlorine gas is adjusted and the power consumption per unit mass of chlorine gas is reduced. The process steps and specific conditions are as follows: 1) Adjust the electrolysis voltage to 2.3V, reduce the concentration of by-product hydrochloric acid to 20%, and adjust the temperature in the electrolytic cell to 60°C.

[0040] 2) chlorination tower mode of operation and parameter are with embodiment 1; Fatty acid methyl ester flow is 270kg / h, and chlorine flow is 177kg / h.

[0041] 3) Other operations and parameters are the same as in Example 1. The absorption tower obtains concentrated hydrochloric acid (20%) as a by-product, and then sends it to the electrolysis device to gener...

Embodiment 3

[0045] In actual production, affected by seasons and downstream applications, the supply of caustic soda produced by chlor-alkali plants is often in short supply. On the contrary, there will be a large surplus of chlorine gas, resulting in slow sales. The process of the present invention can not only utilize the excess chlorine gas of the chlor-alkali plant, but also use the chlorine gas produced by the electrolysis of its by-product hydrochloric acid together to alleviate the problem of excess chlorine gas.

[0046] In this embodiment, the chlorine gas produced by the by-product of electrolysis hydrochloric acid and the chlorine gas in the chlor-alkali plant are used as raw materials to realize the reuse of the by-product hydrochloric acid and alleviate the problem of excess chlorine in the chlor-alkali plant. Its processing steps and specific conditions are as follows:

[0047] 1) Adjust the electrolysis voltage to 2.1V, reduce the concentration of by-product hydrochloric ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com