Shotcrete springback inhibitor and using method thereof

A shotcrete and rebound suppression technology, applied in the field of concrete admixtures, can solve the problems of increasing the risk of shrinkage and cracking of shotcrete, reducing the rebound rate of shotcrete, and detrimental to the personal health of construction workers, and reducing the hydration nucleation potential barrier. , the effect of reducing the risk of cracking and shortening the setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

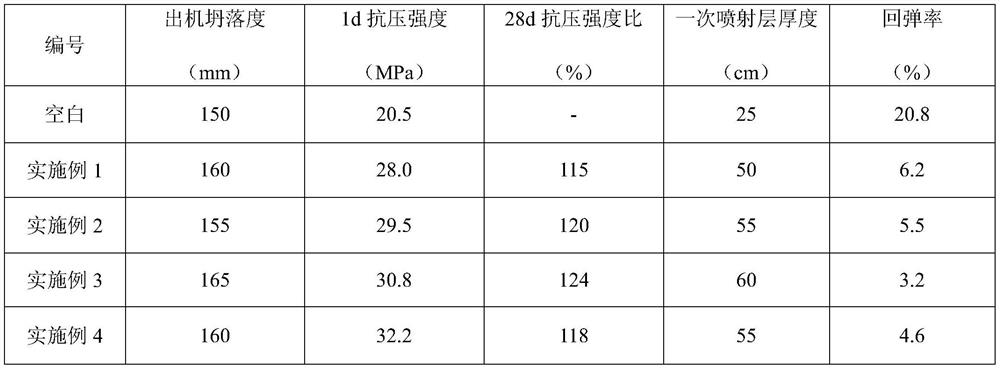

Embodiment 1

[0023] Embodiment 1: The shotcrete rebound inhibitor of the present invention is mixed by the following components and the raw materials of mass percent: composite admixture 50%, nano-calcium silicate 20%, superplasticizer 20% %, redispersible latex powder 2%, water retaining agent 5%, thickener 2%, activator 1.0%; the above-mentioned composite admixture is made of the following raw materials in mass percentage: metakaolin 30%, super 25% fine silica fume, 20% zeolite powder, 15% ground rice husk ash, 5% phosphorus slag powder, and 5% limestone powder; Particle size D50 (median diameter) ≤ 5 μm (using 3 to 5 microns); the above-mentioned ultrafine silica fume is silica powder, of which the silica content is 95%, and the specific surface area is 24000m 2 / kg; the above-mentioned zeolite powder is the active ingredient SiO 2 +Al 2 o 3 White powder with a content of 82% and an average particle size of 170nm; the above-mentioned ground rice husk ash is a powder with a 28d activi...

Embodiment 2

[0025] Embodiment 2: The shotcrete rebound inhibitor of the present invention is mixed by the following components and the raw materials of mass percent: composite admixture 52%, nano-calcium silicate 23%, superplasticizer 15% %, redispersible latex powder 2%, water retaining agent 3%, thickener 4%, activator 1.0%; the above-mentioned composite admixture is made of the following raw materials in mass percentage: metakaolin 37%, super 20% fine silica fume, 20% zeolite powder, 10% ground rice husk ash, 6% phosphorus slag powder, and 7% limestone powder; Particle size D50 (median diameter) ≤ 4 μm (can be 3 to 4 μm); the above-mentioned ultrafine silica fume is silica powder, in which the content of silica is 96%, and the specific surface area is 25000m 2 / kg; the above-mentioned zeolite powder is the active ingredient SiO 2 +Al 2 o 3 White powder with a content of 85% and an average particle size of 120nm; the above-mentioned ground rice husk ash is a powder with an activity i...

Embodiment 3

[0027]Embodiment 3: The shotcrete rebound inhibitor of the present invention is mixed by the following components and the raw materials of mass percentage: composite admixture 55%, nanometer calcium silicate 15%, superplasticizer 20% %, redispersible latex powder 3%, water retaining agent 4%, thickener 2.5%, activator 0.5%; the above-mentioned composite admixture is made of the following raw materials by mass percentage: metakaolin 34%, super 20% fine silica fume, 23% zeolite powder, 12% ground rice husk ash, 5% phosphorus slag powder, and 6% limestone powder; Particle size D50 (median diameter) ≤ 3 μm (can be 2 to 3 microns); the above-mentioned ultrafine silica fume is silica powder, in which the silica content is 93%, and the specific surface area is 24000m 2 / kg; the above-mentioned zeolite powder is the active ingredient SiO 2 +Al 2 o 3 White powder with a content of 85% and an average particle size of 100nm; the above-mentioned ground rice husk ash is a powder with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com