An electrochemical tubular treatment device and method for high-concentration cyanide-containing wastewater

A treatment method and treatment device technology, applied in chemical instruments and methods, water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as complex components, difficult to achieve synchronous high-efficiency treatment, and high TCN concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The tubular reactor device of this embodiment

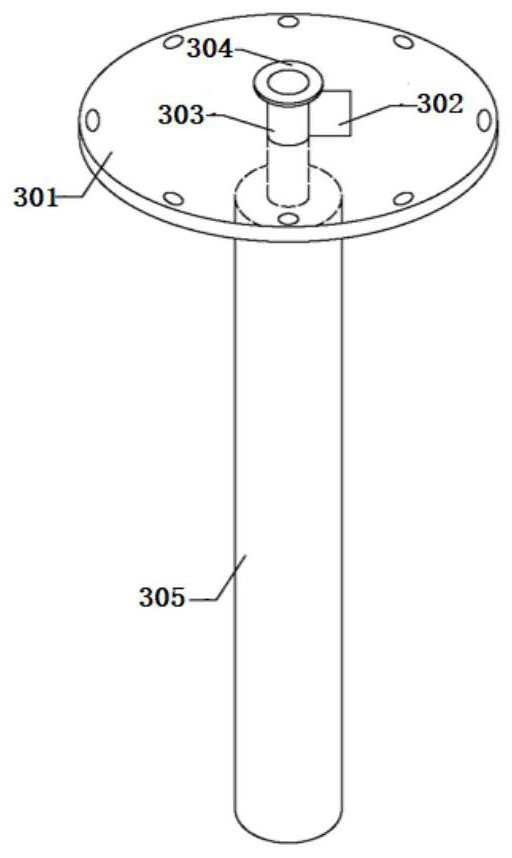

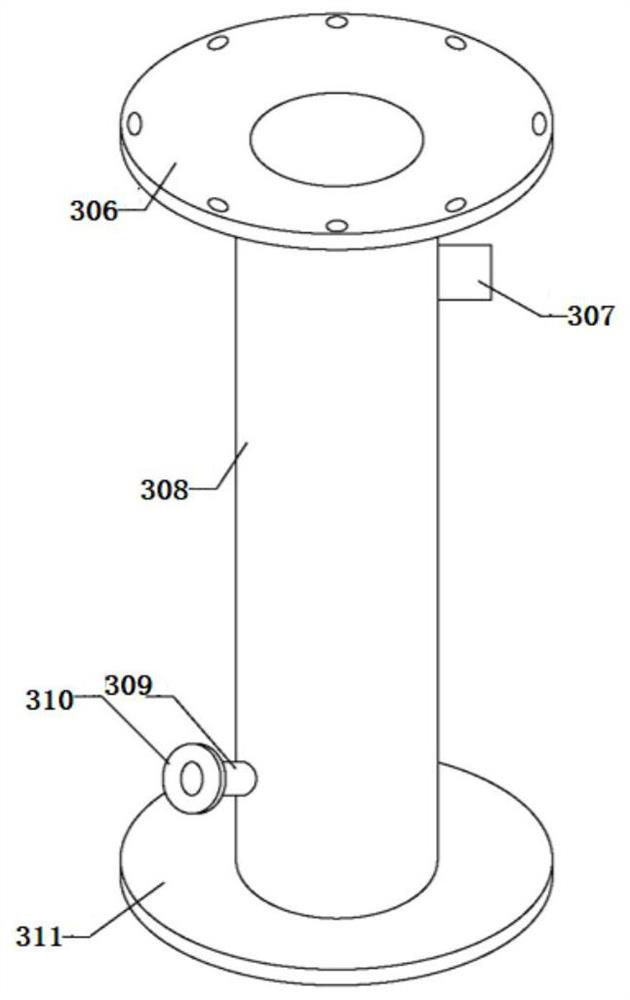

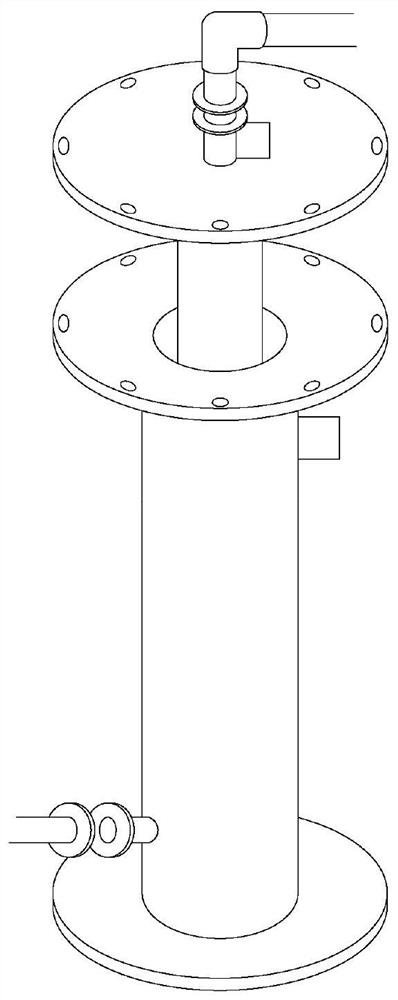

[0072] figure 1 is the anode structure diagram of the tubular reactor device, figure 2 is the cathode 308 structural diagram of the tubular reactor device, image 3 It is the installation structure diagram of the tubular reactor device of the present invention, as Figure 1-Figure 3 As shown, the tubular reactor device includes an anode 305, a cathode 308, an inlet pipe 309 and an outlet pipe 303, the anode 305 is set inside the cathode 308, the inlet pipe 309 communicates with the cathode 308, and the outlet pipe 303 communicates with the anode 305 The anode 305 is a titanium-based metal oxide coated electrode, and the cathode 308 is a stainless steel cathode 308. The anode and the cathode 308 are coaxial and both have a tubular structure, and the distance between the anode 305 and the cathode 308 double tubes is 0.7-1.2 cm.

[0073] The bottom surface of the cathode 308 is installed on the base 311, and the top surf...

Embodiment 2

[0081] Adopt the high-efficiency electrochemical tubular equipment of the present invention to process the cyanide in the cyanide-containing chemical industry wastewater produced by pesticides, comprising the following steps:

[0082] Step 1, preparing a microporous titanium-based ruthenium dioxide anode, the preparation steps are as follows:

[0083] Step 1: Die-cast microporous titanium tubes with a particle size of 43-46 μm into a microporous titanium tube with a pore size of 3-5 μm. After installing the flange, place the tubular microporous titanium substrate in a solution of oxalic acid with a volume concentration of 20-50% and heat it for 60 ~100°C, maintain for 1-3 hours, rinse with deionized water for 3 times, and then soak in deionized water overnight;

[0084] The second step: configure the brushing liquid, configure the ruthenium trichloride isopropanol solution with a mass concentration of 15-20g / L, add 37% (mass concentration) hydrochloric acid according to the am...

Embodiment 3

[0096] Adopt the high-efficiency electrochemical tubular equipment of the present invention to process the cyanide in the cyanide-containing chemical industry waste water of rubber industry, comprise the following steps:

[0097] Step 1. Preparation of microporous titanium-based ruthenium dioxide anode

[0098] The first step: Die-cast microporous titanium tubes with a particle size of 43-46 μm into a microporous titanium tube with a pore size of 3 to 5 μm. After installing the flange, heat the tubular microporous titanium base in a 20 to 50% oxalic acid solution (volume concentration) 60-100°C, maintain for 1-3 hours, rinse with deionized water 5 times, and then soak in deionized water overnight;

[0099] The second step: configure the brushing liquid, configure 15-20g / L ruthenium trichloride isopropanol solution, and add 15-20mL / L37% hydrochloric acid (mass concentration) according to each liter of isopropanol, and stir for 24-48h;

[0100] Step 3: Use a brush to dip in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com