Environment-friendly fluoride-free foam extinguishing agent and preparation method thereof

A foam fire extinguishing agent, environmental protection technology, applied in the direction of fire prevention equipment, etc., can solve the problems of limited application range, toxic fire extinguishing agent, harmful environment, etc., and achieve high fire extinguishing efficiency, good foam stability, and excellent environmental performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

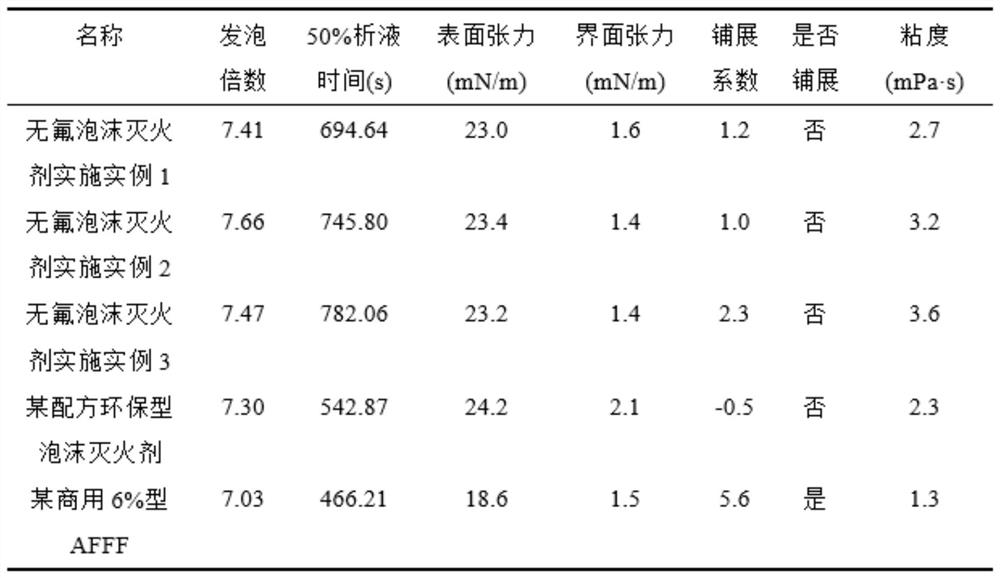

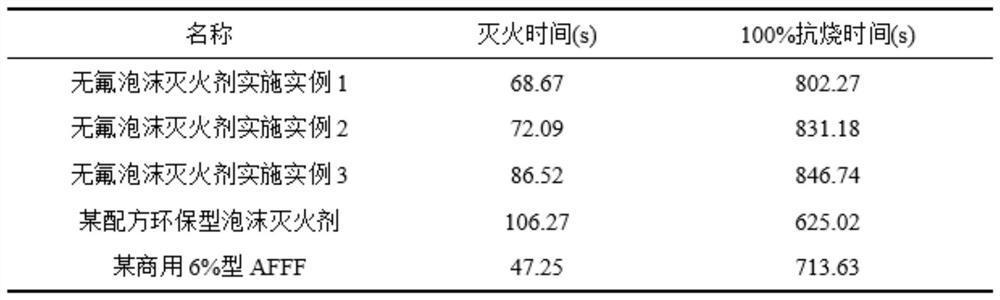

Embodiment 1

[0032] A preparation method of an environment-friendly fluorine-free foam fire extinguishing agent, comprising the following steps:

[0033] S1: Weigh 3 g of sodium lauryl sulfate, 2 g of modified silicone surfactant, 15 g of alkyl glycoside, 2 g of polyethylene glycol, 13 g of water-soluble imidazoline, 10 g of dodecyl dimethyl betaine, Glycol 2g, ethylene glycol 10g, diethylene glycol monobutyl ether 2g; xanthan gum 0.2g, sodium carboxymethylcellulose 0.2g, urea 3g.

[0034]S2: Fully mix the sodium lauryl sulfate, modified silicone surfactant, alkyl glycoside, polyethylene glycol and 15mL of water weighed in step S1 to form mixture A; Imidazoline, dodecyl dimethyl betaine and 7.5 mL of water are fully mixed to form a mixture B; the dodecyl alcohol, ethylene glycol, and diethylene glycol monobutyl ether weighed in step S1 are fully mixed to form a mixture C ; Xanthan gum, carboxymethyl cellulose, and urea weighed in step S1 are fully mixed to form a mixture D;

[0035] S3: ...

Embodiment 2

[0043] A preparation method of an environment-friendly fluorine-free foam fire extinguishing agent, comprising the following steps:

[0044] S1: Weigh 4g of sodium lauryl sulfate, 3g of modified silicone surfactant, 17.5g of alkyl glycoside, 3.5g of polyethylene glycol, 15.5g of water-soluble imidazoline, and dodecyldimethyl betaine 12g, 2.5g of lauryl alcohol, 12.5g of ethylene glycol, 3.5g of diethylene glycol monobutyl ether, 0.3g of xanthan gum, 0.35g of sodium carboxymethylcellulose, 4g of urea.

[0045] S2: Fully mix the sodium lauryl sulfate, modified silicone surfactant, alkyl glycoside, polyethylene glycol and 8.5 mL of water weighed in step S1 to form mixture A; dissolve the weighed water in step S1 Imidazoline, dodecyl dimethyl betaine and 4.3mL of water are fully mixed to form mixture B; lauryl alcohol, ethylene glycol, and diethylene glycol monobutyl ether weighed in step S1 are fully mixed to form a mixture C; Xanthan gum, carboxymethyl cellulose, and urea weigh...

Embodiment 3

[0054] A preparation method of an environment-friendly fluorine-free foam fire extinguishing agent, comprising the following steps:

[0055] S1: Weigh 5 g of sodium lauryl sulfate, 4 g of modified silicone surfactant, 20 g of alkyl glycoside, 5 g of polyethylene glycol, 18 g of water-soluble imidazoline, 14 g of dodecyl dimethyl betaine, 3g of glycol, 15g of ethylene glycol, 5g of diethylene glycol monobutyl ether, 0.4g of xanthan gum, 0.5g of sodium carboxymethylcellulose, and 5g of urea.

[0056] S2: Fully mix the sodium lauryl sulfate, modified silicone surfactant, alkyl glycoside, polyethylene glycol and 2mL of water weighed in step S1 to form mixture A; mix the water-soluble Imidazoline, dodecyl dimethyl betaine and 1 mL of water are fully mixed to form a mixture B; the dodecyl alcohol, ethylene glycol, and diethylene glycol monobutyl ether weighed in step S1 are fully mixed to form a mixture C; Fully mixing the xanthan gum, carboxymethyl cellulose, and urea weighed in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com