Boehmite/inert lithium powder composite slurry, lithium supplementing negative plate, preparation method thereof and lithium ion battery

A technology of composite slurry and boehmite, which is applied in the direction of negative electrodes, electrode manufacturing, secondary batteries, etc., can solve the problems of inability to insert equal amounts of negative electrodes, insufficient space for lithium insertion in negative electrodes, and uneven distribution, so as to improve the first-time efficiency and cycle stability, ensuring cycle and rate characteristics, and improving the effect of safety indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Boehmite / inert lithium powder composite slurry formula: 10 parts by weight of boehmite, 1.5 parts by weight of inert lithium powder, 5 parts by weight of binder (PVDF), 1 part by weight of conductive agent (carbon nanotube conductive paste), Solvent (NMP) 82.5 parts by weight.

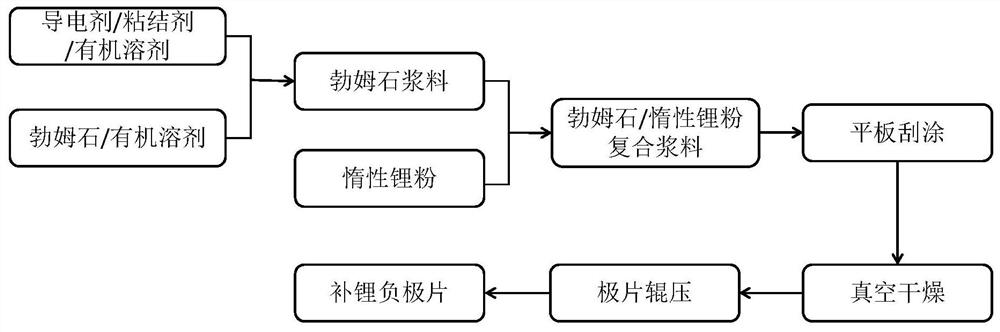

[0063] refer to figure 1 , in a low-humidity environment, add PVDF and NMP into the high-speed dispersion equipment tank according to the above formula, prepare PVDF glue, and add carbon nanotube conductive paste after the dispersion is uniform to prepare conductive glue; disperse boehmite in NMP , to obtain a boehmite dispersion; add the conductive glue to the boehmite dispersion, and stir at high speed for 2 to 3 hours to obtain a stable and dispersed boehmite slurry; then add inert lithium powder to the above boehmite slurry at high speed Stir and disperse evenly, control the temperature at 20-40°C, and stir for 30-60 minutes to obtain a stable and dispersed boehmite / inert lithium powder mix...

Embodiment 2

[0066] Boehmite / inert lithium powder composite slurry formula: 9 parts by weight of boehmite, 2 parts by weight of inert lithium powder, 5 parts by weight of binder (PVDF), 0.8 parts by weight of conductive agent (carbon nanotube conductive paste), Solvent (NMP) 83.2 parts by weight.

[0067] refer to figure 1 , in a low-humidity environment, add PVDF and NMP into the high-speed dispersion equipment tank according to the above formula, prepare PVDF glue, and add carbon nanotube conductive paste after the dispersion is uniform to prepare conductive glue; disperse boehmite in NMP , to obtain a boehmite dispersion; add the conductive glue to the boehmite dispersion, and stir at high speed for 2 to 3 hours to obtain a stable and dispersed boehmite slurry; then add inert lithium powder to the above boehmite slurry at high speed Stir and disperse evenly, control the temperature at 20-40°C, and stir for 30-60 minutes to obtain a stable and dispersed boehmite / inert lithium powder mix...

Embodiment 3

[0069] Boehmite / inert lithium powder composite slurry formula: 8 parts by weight of boehmite, 2.5 parts by weight of inert lithium powder, 5 parts by weight of binder (PVDF), 0.5 parts by weight of conductive agent (carbon nanotube conductive paste), Solvent (NMP) 84 parts by weight.

[0070] refer to figure 1 , in a low-humidity environment, add PVDF and NMP into the high-speed dispersion equipment tank according to the above formula, prepare PVDF glue, and add carbon nanotube conductive paste after the dispersion is uniform to prepare conductive glue; disperse boehmite in NMP , to obtain a boehmite dispersion; add the conductive glue to the boehmite dispersion, and stir at high speed for 2 to 3 hours to obtain a stable and dispersed boehmite slurry; then add inert lithium powder to the above boehmite slurry at high speed Stir and disperse evenly, control the temperature at 20-40°C, and stir for 30-60 minutes to obtain a stable and dispersed boehmite / inert lithium powder mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com