High-entropy alloy for manufacturing flexspline and processing method of flexspline

A technology of high-entropy alloys and processing methods, which is applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems that the service life of the harmonic reducer is difficult to make a major breakthrough, the uniformity of the structure is poor, and there are many metallurgical defects. The product quality is easy to control, the production cost is low, and the performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

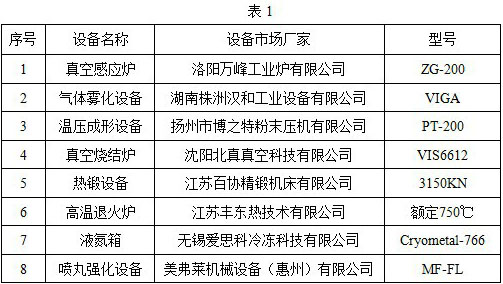

Image

Examples

Embodiment 1

[0055] A method for processing a flexible wheel includes the following steps:

[0056] a. Screen the types of high-entropy alloys, and select high-entropy alloys with FCC-type single-phase solid solution structure as the flexible wheel material;

[0057] b. Design high-entropy alloy chemical composition: high-entropy alloy is FeCoCrNiMo 0.2 C 0.1 , Where the mole ratio of Fe, Co, Cr and Ni is 24.925%, Mo mole ratio is 0.2%, and C mole ratio is 0.1%;

[0058] c. Melting high-entropy alloys: Use vacuum induction furnace to smelt high-entropy alloys. Before loading the furnace, the surface of Fe, Co, Cr, Ni, Mo and C (graphite) raw materials is derusted, dusted and dried; the vacuum is maintained during the melting period At 0.7Pa, the vacuum degree during refining is maintained at 5Pa, the refining temperature is 1530℃, and the retention time is 30min after the refining.

[0059] d. Preparation of high-entropy alloy powder: adopt gas atomization method to prepare high-entropy alloy powd...

Embodiment 2

[0068] A method for processing a flexible wheel includes the following steps:

[0069] a. Screen the types of high-entropy alloys, and select high-entropy alloys with FCC-type single-phase solid solution structure as the flexible wheel material;

[0070] b. Design high-entropy alloy chemical composition: high-entropy alloy is FeCoCrNiMo 0.2 C 0.1 , Where the mole ratio of Fe, Co, Cr and Ni is 24.925%, Mo mole ratio is 0.2%, and C mole ratio is 0.1%;

[0071] c. Melting high-entropy alloys: Use vacuum induction furnace to smelt high-entropy alloys. Before loading the furnace, the surface of Fe, Co, Cr, Ni, Mo and C (graphite) raw materials is derusted, dusted and dried; the vacuum is maintained during the melting period At 5Pa, the vacuum degree during refining is maintained at 30Pa, the refining temperature is 1500℃, and the retention time is 50min after the refining.

[0072] d. Preparation of high-entropy alloy powder: adopt gas atomization method to prepare high-entropy alloy powde...

Embodiment 3

[0081] A method for processing a flexible wheel includes the following steps:

[0082] a. Screen the types of high-entropy alloys, and select high-entropy alloys with FCC-type single-phase solid solution structure as the flexible wheel material;

[0083] b. Design high-entropy alloy chemical composition: high-entropy alloy is FeCoCrNiMo 0.2 C 0.1 , Where the mole ratio of Fe, Co, Cr and Ni is 24.925%, Mo mole ratio is 0.2%, and C mole ratio is 0.1%;

[0084] c. Melting high-entropy alloys: Use vacuum induction furnace to smelt high-entropy alloys. Before loading the furnace, the surface of Fe, Co, Cr, Ni, Mo and C (graphite) raw materials is derusted, dusted and dried; the vacuum is maintained during the melting period At 1.0Pa, the vacuum degree during refining is maintained at 15Pa, the refining temperature is 1510℃, and the retention time is 35min after the refining.

[0085] d. Preparation of high-entropy alloy powder: adopt gas atomization method to prepare high-entropy alloy pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com