Polyurethane prepared by adopting ultraviolet irradiation method and preparation method of polyurethane

A technology of polyurethane and illumination method, which is applied in the field of polyurethane, can solve the problems of decreased mechanical properties, poor interface bonding strength, insoluble and other problems, and achieve the effects of improving bonding strength, accelerating the curing process, and accelerating catalytic reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

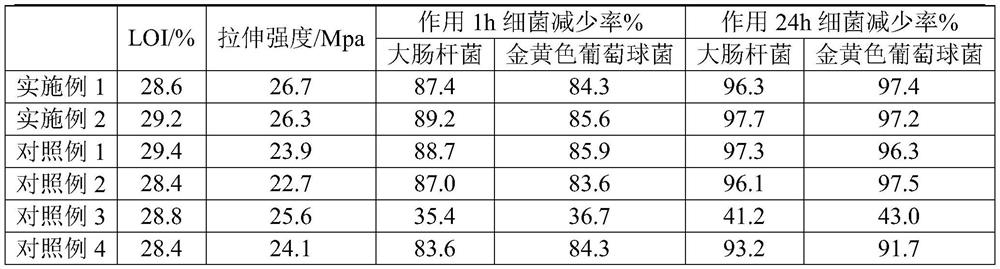

Examples

Embodiment 1

[0023] A kind of preparation method of the polyurethane that adopts ultraviolet light method to prepare, comprises the following steps:

[0024] (1) To prepare an organic modifier, mix 20 g of 500-mesh silicon dioxide and 100 g of water evenly, then add 25 g of carboxymethyl cellulose and 80 g of gelatin, stir evenly, heat to 60° C. for 1 hour, grind after drying, and pass 300 mesh sieve to obtain the organic modifier.

[0025] (2) Heat 13 g of organic modifier and 4 g of diethylene glycol to 60 ° C, and mix them ultrasonically for 20 minutes, then mix the mixture of organic modifier and diethylene glycol with 0.4 dimethylcyclohexylamine g, β-(1,4)-2-amino-2-deoxy-D-glucose 11g, polyurethane prepolymer 45g, mix evenly, at 50mW / cm 2 Under the intensity of ultraviolet light, it was heated to 80°C and reacted for 3 hours to obtain polyurethane.

Embodiment 2

[0027] A kind of preparation method of the polyurethane that adopts ultraviolet light method to prepare, comprises the following steps:

[0028] Heat 18g of the organic modifier and 6g of diethylene glycol in Example 1 to 60°C, and ultrasonically mix for 20min, then mix the mixture of the organic modifier and diethylene glycol with dimethylcyclohexane Amine 1173 0.4g, β-(1,4)-2-amino-2-deoxy-D-glucose 14g, polyurethane prepolymer 48g, mix well, at 40mW / cm 2 Under the intensity of ultraviolet light, it was heated to 90° C. and reacted for 2.5 hours to obtain polyurethane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com