Additive and subtractive composite manufacturing device and method based on in-situ multi-laser regulation and control

A manufacturing method and technology for adding and subtracting materials, which are applied in the field of increasing materials manufacturing, can solve problems such as difficulty in reducing materials processing, and achieve the effect of significant strengthening effect, improving surface quality, and reducing processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

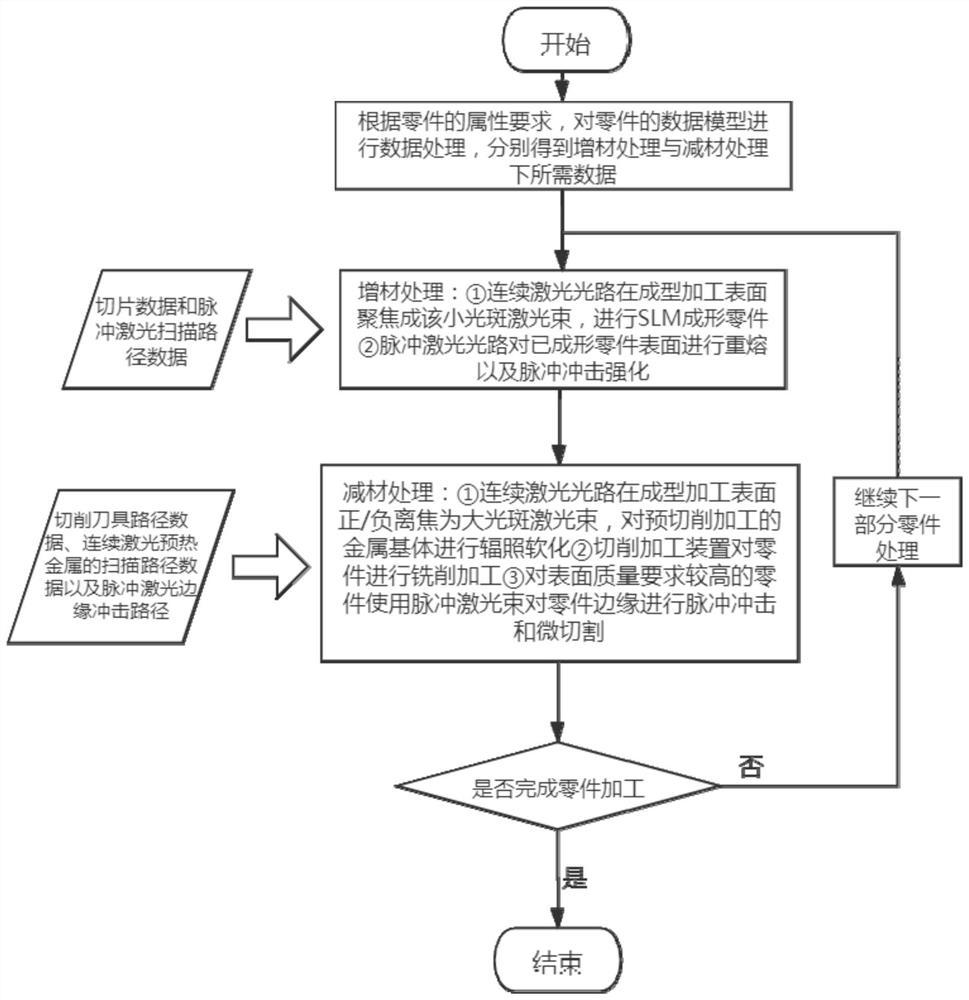

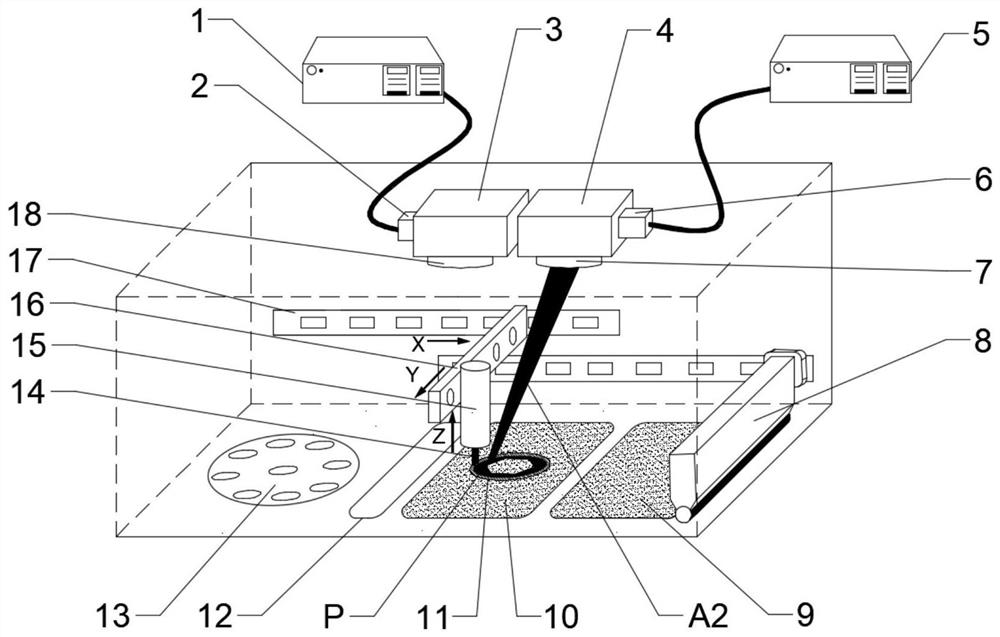

[0048] Such as figure 2 , image 3 , Figure 4As shown, the present invention proposes a composite manufacturing device for adding and subtracting materials based on in-situ multi-laser regulation, including a pulsed laser optical path device, a continuous fiber laser optical path device, a cutting processing device, and a laser selective melting device; Position control, multi-wavelength laser material addition, subtraction and tool milling integrated collaborative forming, to achieve low-defect, high-precision, high-performance parts efficient, integrated additive and subtractive composite manufacturing.

[0049] Further, the pulsed laser optical path device includes a pulsed laser 1, a first collimator 2, a first scanning galvanometer 3 and a first f-θ mirror 18, and the laser light generated by the pulsed laser 1 passes through the first collimator 2 and then controlled by the first scanning galvanometer 3 and focused on the molding surface under the action of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com