Hydroxyapatite coating with biological activity and hierarchical structure on surface of degradable magnesium-based endosteal implant and preparation method

A hydroxyapatite and coating technology, applied in coating, metal material coating process, tissue regeneration and other directions, can solve the problems of insufficient anti-corrosion protection effect, easy to cause inflammation caused by degradation products, insufficient anti-corrosion ability, etc. Beneficial for adhesion and proliferation, good cytocompatibility and bioactivity, improved corrosion resistance and bioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

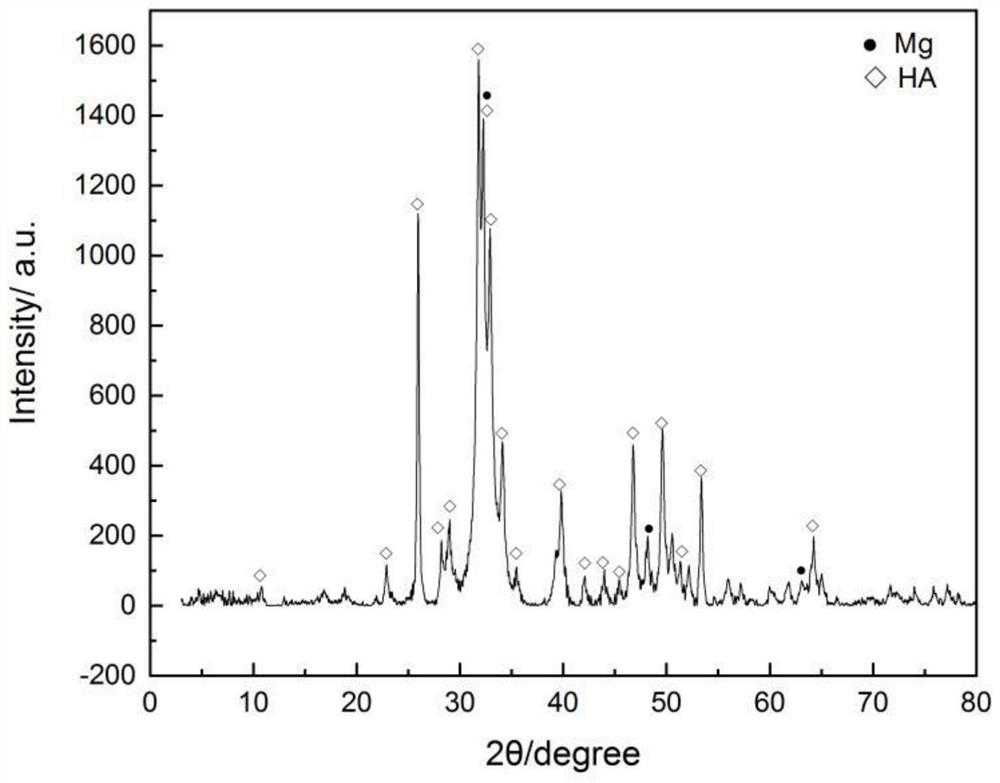

[0039] Preparation of bioactive hydroxyapatite coating on the surface of Mg-Nd-Zn-Zr alloy bone screws. Specific steps are as follows:

[0040] 1) Firstly, the Mg-Nd-Zn-Zr alloy is made into a Φ14×3mm sample, polished with 320#, 1200#, 3000# water sandpaper in sequence, ultrasonically cleaned with anhydrous ethanol for 5min×2 times, and dried.

[0041] 2) Soak the sample in 40% hydrofluoric acid at 30° C. for 6 hours while shaking on a shaker. Rinse with deionized water and absolute ethanol in turn, and blow dry.

[0042] 3) The fluorinated sample is in NaNO 3 : Ca(H 2 PO 4 ) 2 :H 2 o 2 = 4:3:1 (wt%) calcium-phosphorus solution at room temperature for 6 hours. The precursor brushite DCPD coating was prepared.

[0043] 4) Preparation of hydrothermal reaction liquid: take Ca-EDTA:NaH 2 PO 4 =1:1 (substance ratio), add deionized water to dissolve, then add 1mol / L NaOH solution to adjust pH=9. Soak the fluorinated Mg-Nd-Zn-Zr alloy covered with DCPD coating in the hydr...

Embodiment 2

[0046] Bioactive hydroxyapatite coating was prepared on the surface of ZK60 (Mg-Zn series) alloy bone plate. Specific steps are as follows:

[0047] 1) First, make a Φ14×3mm sample of ZK60 alloy, polish it with 320#, 1200#, 3000# water sandpaper in turn, ultrasonically clean it with absolute ethanol for 5min×2 times, and blow dry.

[0048] 2) Soak the sample in 30% hydrofluoric acid at 20° C. for 12 hours while shaking on a shaker. Rinse with deionized water and absolute ethanol in turn, and blow dry.

[0049] 3) The fluorinated sample is in NaNO 3 : Ca3(PO 4 ) 2 :H 2 o 2 =7:3:2 (wt%) calcium-phosphorus solution at room temperature and soak for 36h. The precursor brushite DCPD coating was prepared.

[0050] 4) Preparation of hydrothermal reaction solution: take Ca-EDTA:Na 2 HPO 4 =1.67:1 (substance ratio), add deionized water to dissolve, then add 1mol / L NaOH solution to adjust pH=6.5. Soak the above-mentioned fluorinated ZK60 alloy covered with DCPD coating in the ...

Embodiment 3

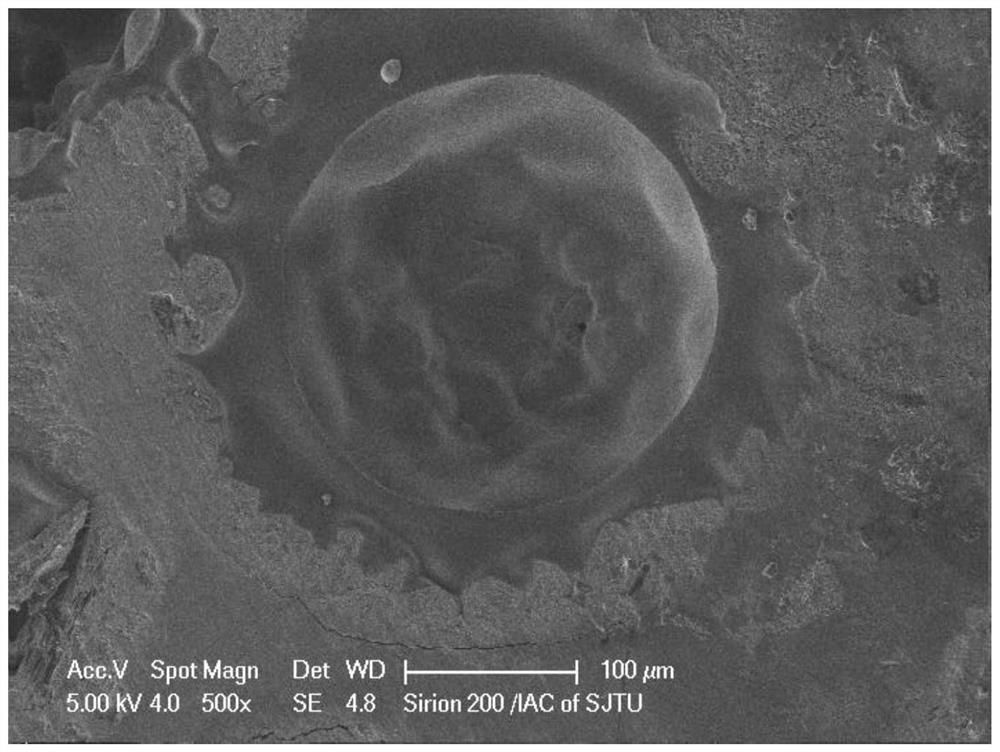

[0053] Preparation of bioactive hydroxyapatite coating on the surface of pure magnesium porous bone tissue engineering scaffolds for tissue engineering. Specific steps are as follows:

[0054] 1) First, make a Φ10×2mm sample of porous pure magnesium, ultrasonically clean it with acetone and absolute ethanol for 5 minutes, and dry it.

[0055] 2) Soak the sample in 20% hydrofluoric acid at 10° C. for 48 hours while shaking on a shaker. Rinse with deionized water and absolute ethanol in turn, and blow dry.

[0056] 3) The fluorinated sample is in NaNO 3 : Ca3(PO 4 ) 2 : CaHPO 4 :H 2 o 2 =5:2:1:1 (wt%) calcium-phosphorus solution at room temperature for 36 hours. The brushite DCPD coating on the surface of porous pure magnesium was prepared.

[0057] 4) Preparation of hydrothermal reaction solution: take Ca-EDTA:Na 3 PO 4 =2:1 (substance ratio), add deionized water to dissolve, then add 1mol / L NaOH solution to adjust pH=8.5. Soak the fluorinated porous pure magnesium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com