Intelligent gas field system and method for self-adaption and intelligent analysis and decision making

An intelligent analysis and self-adaptive technology, applied in earthwork drilling, wellbore/well valve devices, and production fluids, etc., can solve problems such as abnormal production, incomplete data, and inability to intelligently adjust parameters to achieve high-quality production guarantee Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

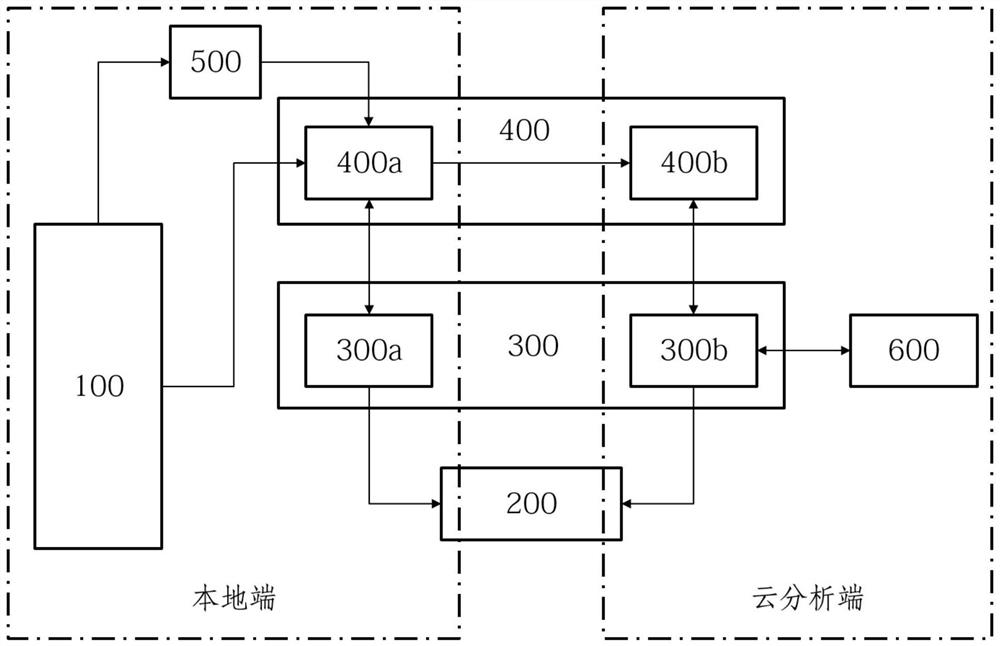

[0027] This embodiment discloses an intelligent gas field system for adaptive and intelligent analysis and decision-making. Such as figure 1 As shown, the system includes a production status acquisition module 100 , a production parameter adjustment module 200 , a working condition identification and prediction module 300 and an intelligent service module 400 .

[0028] Production status collection module 100: used to collect the operating parameters of the gas production device. For example, the production status collection module 100 collects the load, displacement, dynamometer diagram, temperature, production, oil jacket pressure, valve opening and electrical parameter data of the gas production device. The production status acquisition module 100 includes an electrical parameter acquisition module, a temperature sensor, a pressure sensor, a dynamic liquid level measuring instrument, an integrated dynamometer, a flow sensor, an angular displacement sensor, and the like.

...

Embodiment 2

[0038] This embodiment may be a further improvement and / or supplement to Embodiment 1, and repeated content will not be repeated here. In the case of no conflict or contradiction, the whole and / or part of the content of the preferred implementations of other embodiments may serve as supplements to this embodiment.

[0039] This embodiment provides a variety of fault diagnosis methods, which are applied to the intelligent application system of the gas production device:

[0040] 1. The technique of fault diagnosis of gas production devices based on dynamometer diagrams is based on the obtained high-quality dynamometer diagrams to establish a template library and a feature vector library of gas production well condition diagrams, and to use SVM and BR neural networks for machine learning to form Fault dynamic diagnosis model to realize fault identification of gas production equipment. Since the feature extraction method is used to abstract the main features of the outline of th...

Embodiment 3

[0057] This embodiment may be a further improvement and / or supplement to Embodiment 1, 2 or their combination, and repeated content will not be repeated. In the case of no conflict or contradiction, the whole and / or part of the content of the preferred implementations of other embodiments may serve as supplements to this embodiment.

[0058] Preferably, the cloud server 400b establishes a communication connection with the local server 400a corresponding to each gas production device via the wellhead Internet of Things device. The local server 400b corresponding to each gas production device in the cluster well site sends the operating parameters to the cloud server 400b. The cloud server 400b can obtain the operating parameters of each gas production device in the cluster well site via the local server 400a. The cloud server 400b can predict the occurrence time of the power peak under normal working conditions or abnormal working conditions, so that the cloud server 400b can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com