Oil sludge demulsifier and preparation method thereof

A demulsifier and oil sludge technology, which is applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of long treatment cycle, flammable and explosive, high energy consumption, etc. The effect of science, easy industrial application, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

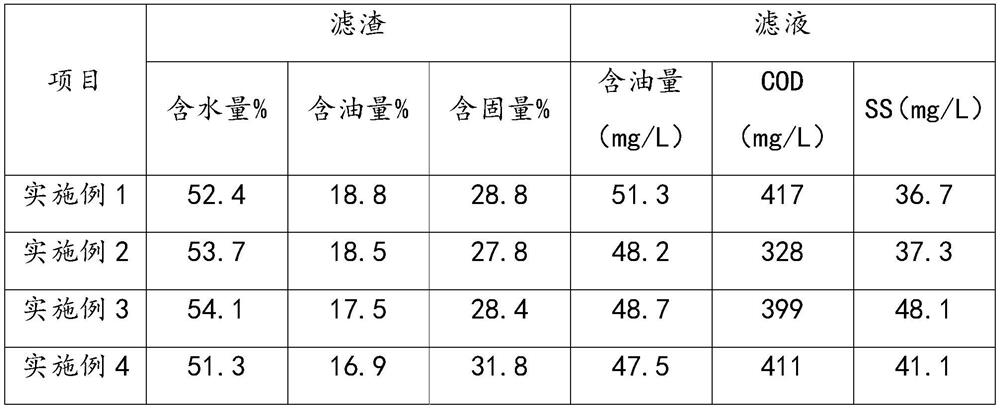

Examples

Embodiment 1

[0022] The preparation method of oil sludge demulsifier is as follows: weigh cetyltrimethylammonium bromide, polyacrylamide and ethanol at a mass ratio of 30:40:30, and mix cetyltrimethylammonium bromide and ethanol at 60 Mix evenly at a speed of 800 rpm, cool to 40 °C, add polyacrylamide, and stir at a speed of 1600 rpm for 30 minutes at 20 °C to obtain a sludge demulsifier.

Embodiment 2

[0024] The preparation method of oil sludge demulsifier is as follows: weigh imidazoline oxide ethylene oxide propylene polymer, polyacrylamide and methanol according to the mass ratio of 9:0.5:30, and mix imidazoline oxide ethylene oxide propylene polymer and methanol at 60°C at 600rpm Mix evenly at a rotating speed, cool to 30°C, add polyacrylamide, and stir at 30°C at a speed of 1500rpm for 30 minutes to obtain a sludge demulsifier.

Embodiment 3

[0026] The preparation method of oil sludge demulsifier is as follows: weigh polyol ethylene oxide propylene oxide polymer, isopropanol, and fatty acid amide at a mass ratio of 50:20:60, and mix polyol ethylene oxide propylene oxide polymer and isopropanol at 70°C Mix evenly at a speed of 500 rpm, cool to 20°C, add fatty acid amide, and stir at a speed of 1500 rpm for 20 minutes at 20°C to obtain a sludge demulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com