A kind of silk protein/gelatin composite material and its application

A composite material and silk protein technology, which is applied in the field of silk protein/gelatin composite materials and the preparation of internal fixation systems, can solve the problems of thermal stability, swelling in vivo and unsatisfactory mechanical stability, etc., to promote cell growth and The effect of tissue recovery, high mechanical strength, and not easy to break nails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Preparation of silk protein / gelatin composite material

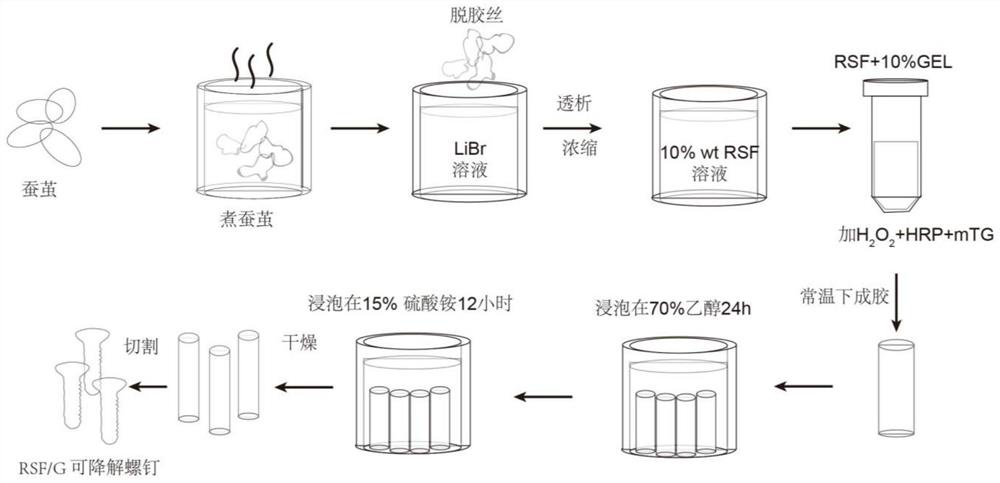

[0052] see figure 1 , the preparation of silk protein / gelatin composite material includes the following steps:

[0053] 1. Degumming the natural silkworm cocoons with a sodium carbonate aqueous solution with a concentration of 0.5% and drying them to make degummed silk; then according to the mass ratio of silkworm cocoons: lithium bromide solution 1:10, dissolve with a concentration of 0.8% lithium bromide solution, dialysis desalination, Concentrated to make a 10% wt regenerated silk protein solution.

[0054] 2. Mix 9 mL of silk protein solution obtained in step 1 and 1 mL of 30% wt gelatin solution, then add 900 U / mL horseradish peroxidase and 0.5% v / v hydrogen peroxide solution (concentration 30%) and 20000 U Glutamine transaminase / mL, and gelatinized in a water bath at 37°C after mixing.

[0055] 3. The silk protein / gelatin gel obtained in step 2 is soaked in 70% alcohol for 24-36 hours, and then...

Embodiment 2

[0057] Example 2 Processing of Bone Nails and Bone Plates

[0058] The silk protein / gelatin composite material obtained in Example 1 was processed into columnar or massive mother embryos, and then processed into bone nails and bone plates by a multi-axis CNC machining lathe to obtain degradable silk protein / gelatin composite bone nails and bone nails. Internal fixation system consisting of bone plates. figure 2 A photograph of the bone screw is shown, which is a silk protein / gelatin composite screw. The size of the bone nail is: the diameter of the screw is 2 mm, the length of the screw is 5 mm, and the diameter of the end cap is 3.6 mm.

[0059] For comparison, regenerated silk protein (RSF) material and PLGA were used as raw materials to manufacture screws of the same size using a multi-axis CNC machining lathe.

Embodiment 3

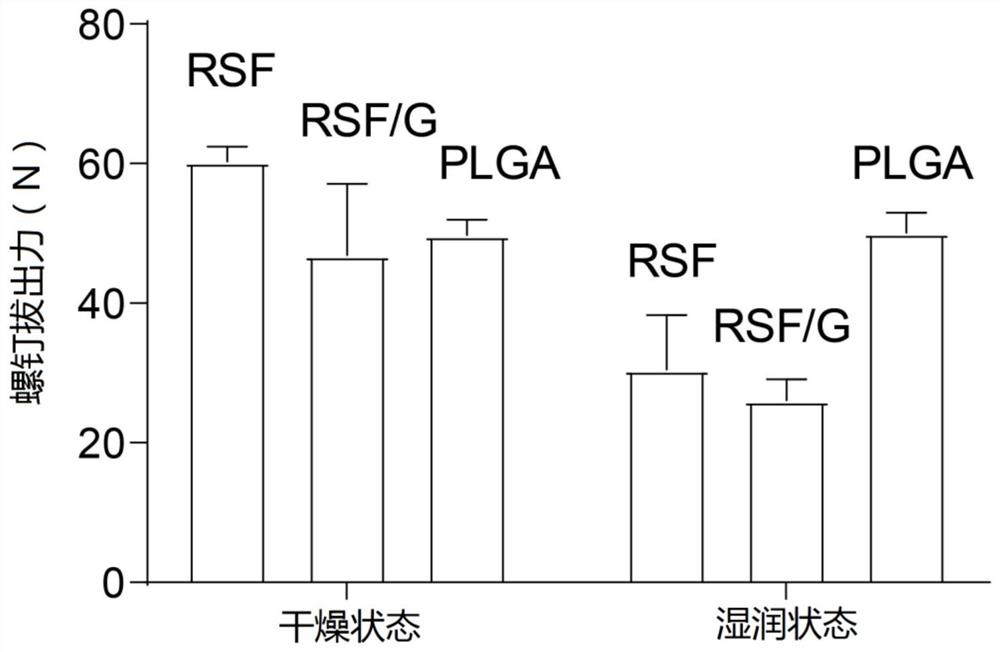

[0060] Example 3 Mechanical test of external pull-out force of screws

[0061] For the silk protein / gelatin composite screw (RSF / G), regenerated silk protein screw (RSF) and PLGA screw obtained in Example 2, the pull-out force in the dry state and the wet state were tested according to the following methods.

[0062] According to American Society for Testing and Materials (ASTM) standard F1839, using an Instron 5966 (Instron, USA) universal chemistry instrument, a custom-made screw cap stainless steel holder and an artificial bone block (Sawbones, USA) paired The pullout force strength of RSF / G, RSFRSF / G and PLGA screws was tested. Artificial bone blocks were pre-embedded in bone cement, fixed to the bottom of an Instron 5966 test frame, and drilled with a drill (1.7 mm diameter). Screw the RSF / G and RSF screws into the artificial bone block, and then connect the Instron mechanics after clamping the screw cap with a holder. The screw was gradually pulled out of the artificia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com