High-temperature-resistant nitrification inhibitor as well as preparation method and application thereof

A technology of nitrification inhibitor and high temperature resistance, which is applied in application, agricultural gas emission reduction, fertilizer mixture, etc. It can solve the problems of unusable, low environmental pollution, and high temperature resistance, and achieve low cost, low environmental pollution, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

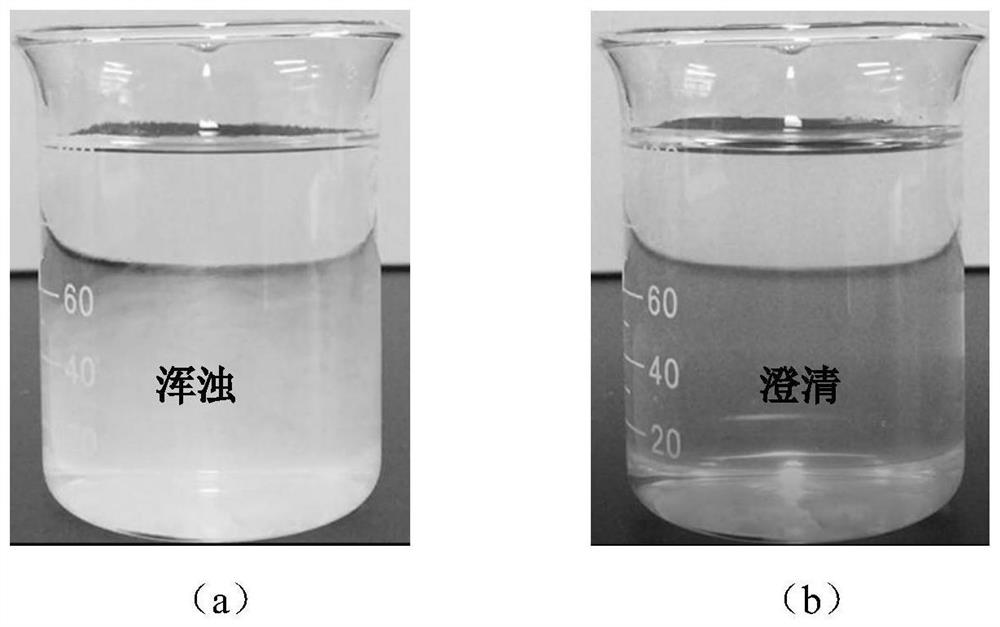

Image

Examples

Embodiment 1

[0035] A high temperature resistant nitrification inhibitor, the steps are as follows:

[0036] Step 1: Add 200g distilled water, 20g calcium silicate and 27g mass concentration of 98% hydrochloric acid aqueous solution to the reaction kettle with temperature sensor and stirrer, mix and disperse evenly, and heat it from Room temperature rises to 80°C;

[0037] Step 2: Add 60g of acrylic acid and 45g of 3,4-dimethylpyrazole to the system of Step 1, mix and disperse evenly;

[0038] Step 3: slowly add 9g composite initiator (ammonium persulfate / ammonium bicarbonate / tert-butyl peroxybenzoate, ammonium persulfate, ammonium bicarbonate and tert-butyl peroxybenzoate) in step (two) system The molar ratio is 1:1:1); then react at 80°C for 2h, and finally cool down to collect the product. The above reactions do not require additional introduction of protective gas.

[0039] The nitrification inhibitor prepared in this example was tested by gel permeation chromatography, and its numb...

Embodiment 2

[0043] A high-temperature-resistant nitrification inhibitor, as described in Example 1, the difference is: the heating rate in step 1 is 1°C / min, and the heating temperature is 40°C, and other steps and conditions are the same as in Example 1.

Embodiment 3

[0045] A high temperature resistant nitrification inhibitor, as described in Example 1, the difference is: the quality of the composite initiator, calcium silicate, hydrochloric acid, 3,4-dimethylpyrazole, acrylic acid, distilled water is respectively 11g, 44g, 35g, 63g, 76g and 400g; other steps and conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com