Preparation method of graphite spherical shell sheet

A graphite ball and graphite technology, applied in the field of materials, can solve the problems of unsatisfactory conductivity and stability of carbon materials, and achieve the effects of high capacity, excellent transmission performance, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

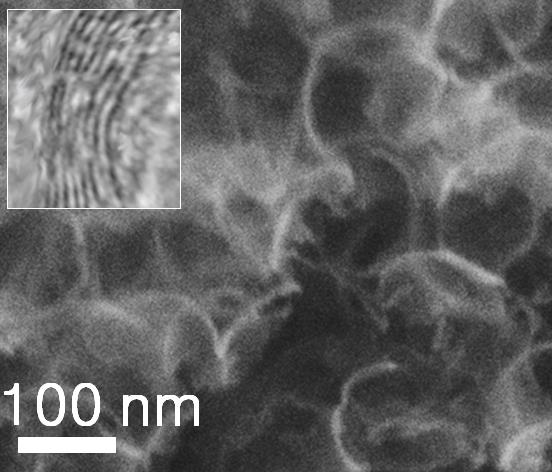

Embodiment 1

[0025] Mix 2.5 g of polystyrene spheres with an average diameter of 150 nm, 2.5 g of glucose, 0.3 g of ferric nitrate and 40 mL of deionized water, ultrasonically disperse it into a uniform emulsion, and pour it into a 50 mL Teflon-lined In a high pressure reactor. Seal the autoclave, place it in an oven, heat up to 180°C, and keep it warm for 16 hours. After cooling, the solid was collected by filtration and dried at 80°C for 1 hour. The dried product was placed in a microwave oven and heated at 300-400° C. in an air atmosphere for 4 minutes. Then, the product was placed in a tube furnace, and the temperature was raised to 1000 °C at a rate of 10 °C / min under a nitrogen atmosphere and kept for 1 hour. After cooling to room temperature, use 1 mol L -1 Soak in hydrochloric acid to remove iron, then wash the sample with deionized water until neutral, and finally dry at 80 °C to obtain graphite spherical shell sheets with a thickness of 3-12 nm and a specific surface area of ...

Embodiment 2

[0028] Mix 1 g of polystyrene spheres with an average diameter of 100 nm, 2 g of glucose, 0.2 g of potassium ferrocyanide, and 20 mL of deionized water, ultrasonically disperse it into a uniform emulsion, and pour it into a polytetrafluoroethylene liner with a volume of 50 mL. In the autoclave of vinyl fluoride. Seal the autoclave, place it in an oven, heat up to 160°C, and keep it warm for 24 hours. After cooling, the solid was collected by filtration and dried at 80°C for 1 hour. The dried product was placed in a microwave oven and heated for 3 minutes at 350-450° C. in an air atmosphere. Then, the product was placed in a tube furnace, and the temperature was raised to 1100 °C at a rate of 10 °C / min under a nitrogen atmosphere, and kept for 0.5 hours. After cooling to room temperature, use 1 mol L -1 Soak in hydrochloric acid to remove iron, then wash the sample with deionized water until neutral, and finally dry at 80 °C to obtain graphite spherical shell sheets with a t...

Embodiment 3

[0030] Mix 1 g of polystyrene spheres with an average diameter of 2 μm, 0.3 g of glucose, 0.06 g of ferric chloride, and 30 mL of deionized water, ultrasonically disperse into a uniform emulsion, and pour into a volume of 50 mL lined with polytetrafluoroethylene in the high pressure reactor. Seal the autoclave, place it in an oven, heat up to 200°C, and keep it warm for 8 hours. After cooling, the solid was collected by filtration and dried at 80°C for 1 hour. The dried product was placed in a microwave oven and heated for 30 seconds at 500-600° C. in an air atmosphere. Then, the product was placed in a tube furnace, and the temperature was raised to 600 °C at a rate of 10 °C / min under a nitrogen atmosphere and kept for 4 hours. After cooling to room temperature, use 1mol L -1 Soak in hydrochloric acid to remove iron, then wash the sample with deionized water until neutral, and finally dry at 80 °C to obtain graphite spherical shell sheets with a thickness of about 20 nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com