Bioactive porous poly-ether-ether-ketone as well as preparation method and application thereof

A polyetheretherketone and biologically active technology, which is applied in the field of bioactive porous polyetheretherketone material and its preparation, can solve the problems of lack of osteoconduction and bone integration performance and application limitations, and achieve good sustained release effect and drug loading Convenience, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

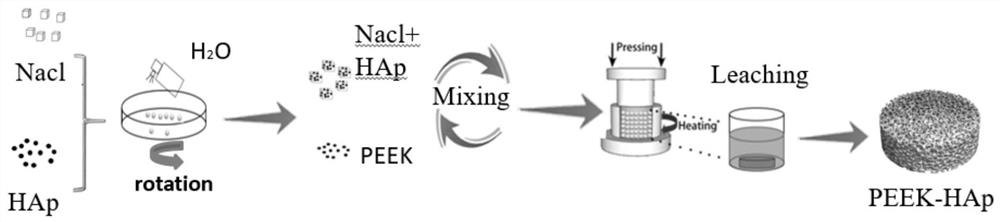

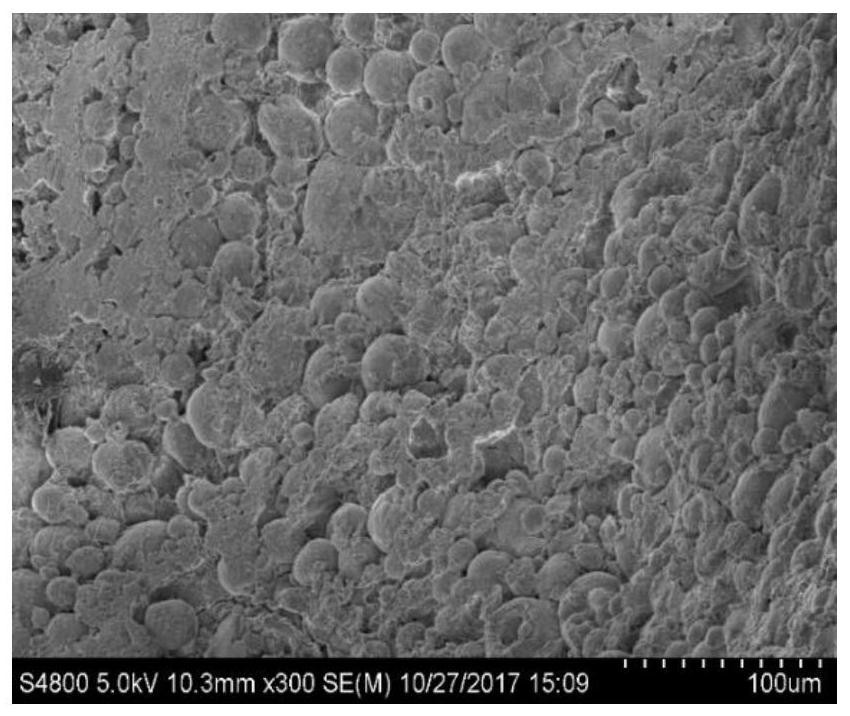

[0039] (1) All the raw materials in the example are commercially available. Screen 450 μm ~ 800 μm NaCl particles and 1 μm ~ 20 μm hydroxyapatite microspheres, and wet the surface of NaCl particles according to the mass ratio of 100:3 to make hydroxyapatite Stone microspheres are evenly adhered to the surface of NaCl particles and sintered at 700°C for 2 hours to construct composite porogenic particles;

[0040](2) Mix the composite porogenic particles and PEEK powder uniformly according to the mass ratio of 6:1, compact under the pressure of 10MPa, sinter at 380°C for 30min, soak in deionized water at 60°C for 4h, and then the active porous polyetheretherketone can be obtained The materials were ultrasonically cleaned with distilled water, placed in an oven at 60°C for 3 hours, and stored for later use;

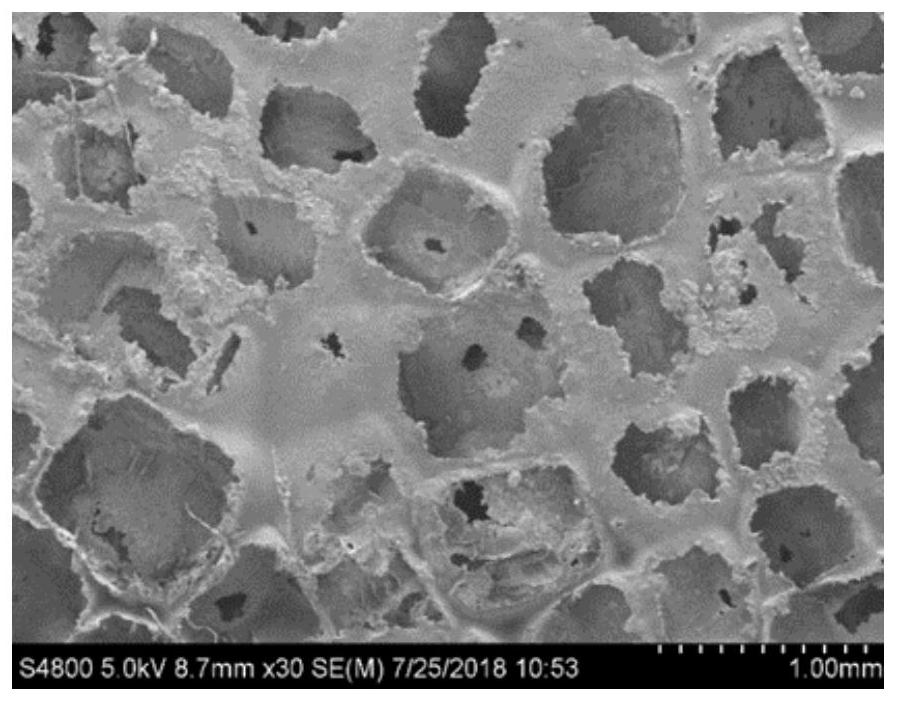

[0041] (3) The porosity of the active porous polyetheretherketone is 82%, the compressive yield strength is 1.52MPa, and the compressive modulus is 54.3MPa;

[0042] (4) Pr...

Embodiment 2

[0045] (1) Screen 450 μm ~ 800 μm NaCl particles and 1 μm ~ 20 μm hydroxyapatite microspheres, and wet the surface of NaCl particles according to the mass ratio of 100:3, so that the hydroxyapatite microspheres evenly adhere to the NaCl particles On the surface, sinter at 700°C for 2 hours to construct composite porogenic particles;

[0046] (2) Mix the composite porogenic particles and PEEK powder uniformly according to the mass ratio of 6:1, compact under the pressure of 10MPa, sinter at 380°C for 30min, soak in deionized water at 60°C for 4h, and then the active porous polyetheretherketone can be obtained The materials were ultrasonically cleaned with distilled water, placed in an oven at 60°C for 3 hours, and stored for later use;

[0047] (3) The porosity of the active porous polyetheretherketone is 82%, the compressive yield strength is 1.52MPa, and the compressive modulus is 54.3MPa;

[0048] (4) Prepare 10mg / ml BMP-2 solution, keep the negative pressure adsorption at ...

Embodiment 3

[0051] (1) Screen 450 μm ~ 800 μm NaCl particles and 1 μm ~ 20 μm hydroxyapatite microspheres, and wet the surface of NaCl particles according to the mass ratio of 100:3, so that the hydroxyapatite microspheres evenly adhere to the NaCl particles On the surface, sinter at 700°C for 2 hours to construct composite porogenic particles;

[0052] (2) Mix the composite porogenic particles and PEEK powder uniformly according to the mass ratio of 6:1, compact under the pressure of 10MPa, sinter at 380°C for 30min, soak in deionized water at 60°C for 4h, and then the active porous polyetheretherketone can be obtained The materials were ultrasonically cleaned with distilled water, placed in an oven at 60°C for 3 hours, and stored for later use;

[0053] (3) The porosity of the active porous polyetheretherketone is 82%, the compressive yield strength is 1.52MPa, and the compressive modulus is 54.3MPa;

[0054] (4) Prepare icariin solution of 10mg / ml, keep the negative pressure adsorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com