Lithium-sulfur battery, positive electrode and negative electrode materials of lithium-sulfur battery and preparation method thereof

A technology for lithium-sulfur batteries and negative electrode materials, which is applied in the manufacture of battery electrodes, lithium batteries, and electrolyte batteries, can solve the problems of increasing electrolyte viscosity, capacity decay, and low conductivity, and achieve the effect of improving battery safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method for lithium-sulfur battery cathode and anode materials, the steps are as follows:

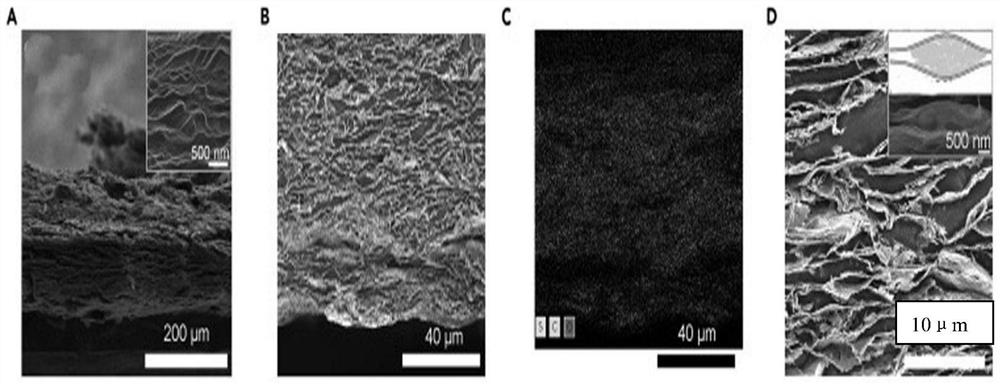

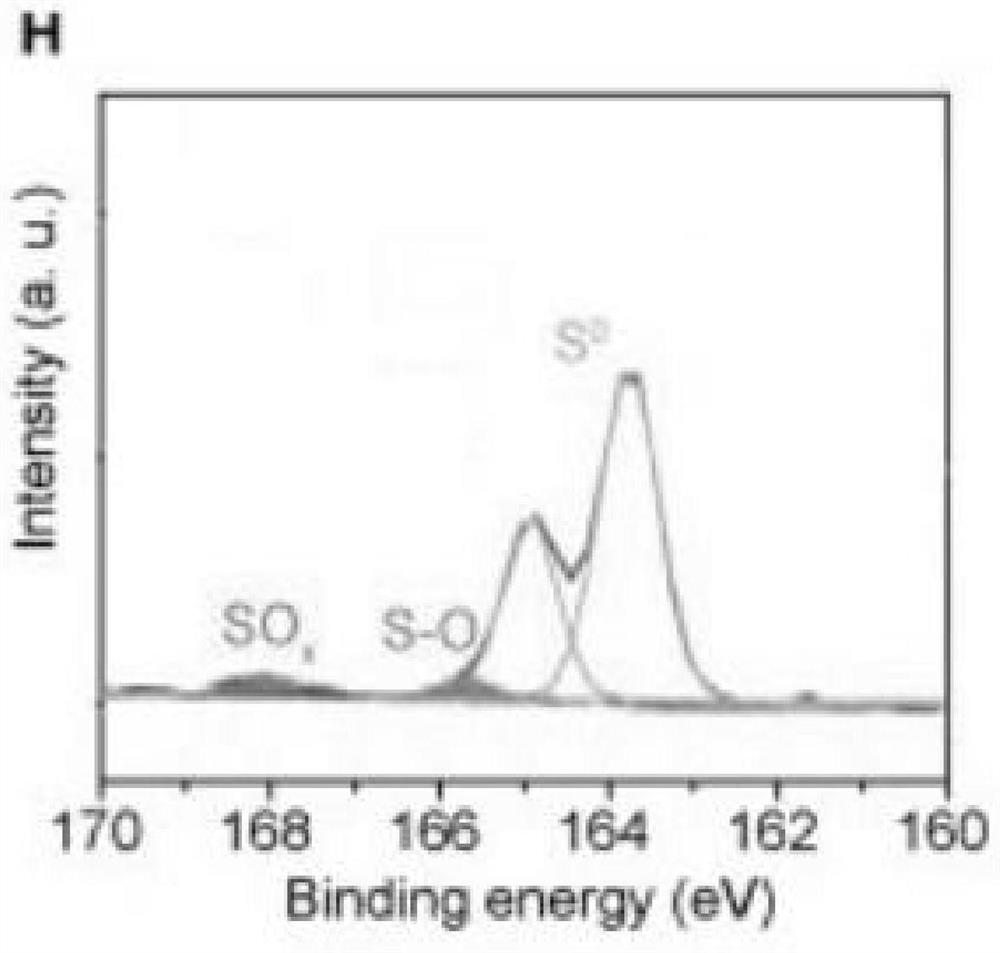

[0041] (1) Under a nitrogen atmosphere, graphene oxide was heated to 350° C. and kept for 0.2 h to obtain reduced graphene.

[0042] (2) Under nitrogen atmosphere, mix the reduced graphene described in step (1) with sulfur powder according to the mass ratio of 0.3:0.7, then heat to 155°C in a roller table atmosphere furnace and keep it warm for 1h to melt the sulfur, And fully absorbed into the nano-space structure of the reduced graphene to form a positive electrode active material with strong adsorption capacity for sulfur; that is, the lithium-sulfur battery positive electrode material.

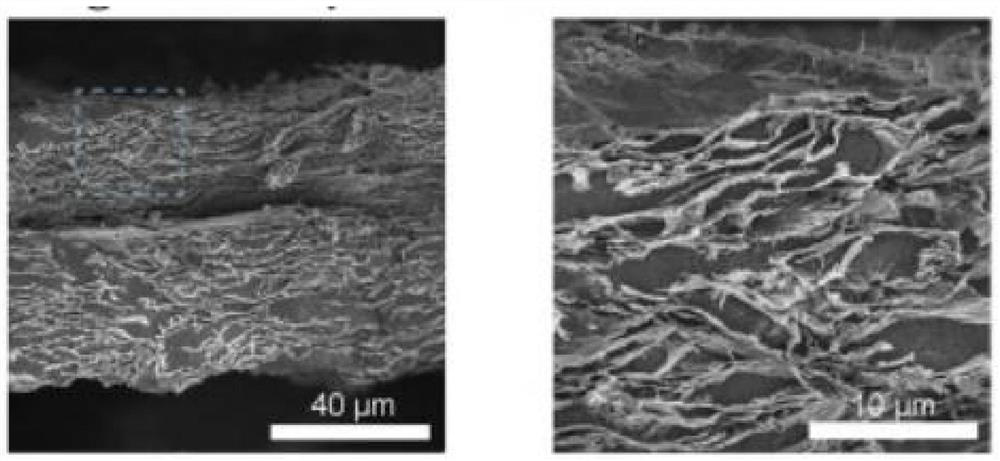

[0043] (3) Under nitrogen atmosphere, mix the reduced graphene described in step (1) with lithium powder according to the mass ratio of 0.4:0.6, then heat to 350°C in a roller table atmosphere furnace and keep it warm for 1h to melt lithium, And fully absorbed into the nano-spac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com