Induction element of pyroelectric sensor, manufacturing method of induction element and pyroelectric sensor

A technology of a pyroelectric sensor and a manufacturing method, which is applied in the directions of thermoelectric devices with thermal changes in dielectric constant, electric radiation detectors, etc., can solve the problems of difficulty in achieving further thinning of thickness, high polarization process voltage, and high production scrap rate. , to improve the pyroelectric coefficient, realize large-scale processing, and facilitate mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

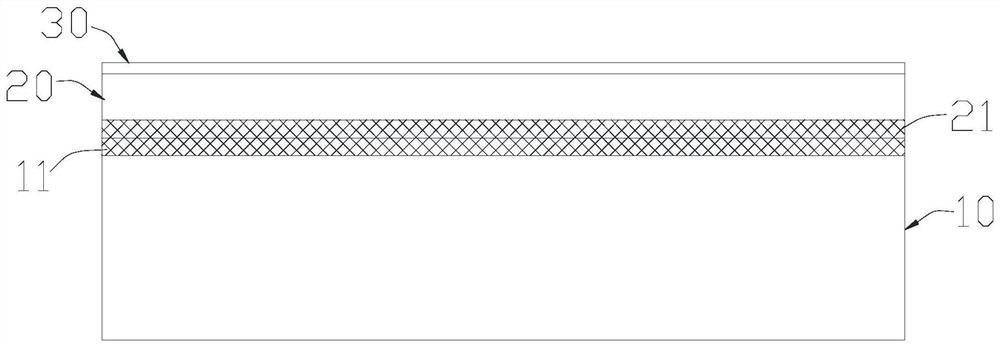

[0030] like figure 1 As shown, the sensing element of the pyroelectric sensor according to an embodiment of the present invention may include an insulating substrate 10, a PZT sheet stacked on the insulating substrate 10, and a metal layer disposed between the insulating substrate 10 and the PZT sheet 20. A bonding layer, an electrode layer 30 disposed on the surface of the PZT sheet 20 away from the insulating substrate 10 .

[0031] Among them, the thickness of the PZT sheet 20 is 0.015mm-0.065mm, which is ultra-thin compared with the existing thickness of 0.1mm, and realizes high pyroelectric response and low internal resistance of the sensing element. The metal bonding layer is formed by bonding the metal coating f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com