Preparation method of high-strength and high-toughness graphene reinforced aluminum matrix composite

A composite material and a technology for strengthening aluminum matrix, which is applied in the field of preparation of aluminum matrix composite materials, can solve the problems of strength-toughness inversion, uneven dispersion of graphene, etc., and achieves enhanced interface bonding, good economic benefits, and increased crack propagation paths. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Specific embodiment one: the preparation method of high-strength and tough graphene-reinforced aluminum-based composite material in this embodiment is carried out according to the following steps:

[0028] 1. Weighing

[0029] Weighing 0.3% to 5% of graphene microflakes and 95% to 99.7% of aluminum metal powder by mass fraction;

[0030] 2. Pre-dispersion of graphene microflakes

[0031] Ultrasonic disperse the graphene microflakes weighed in step 1 in distilled water for 90 to 120 minutes to obtain an aqueous graphene microflake solution; add the aluminum metal powder weighed in step 1 to the graphene microflake aqueous solution, and stir at room temperature for 60 to 100 min. 90min, then carry out suction filtration, dry after suction filtration, put the powder obtained after drying into a ball mill tank and carry out ball milling to obtain a mixed powder;

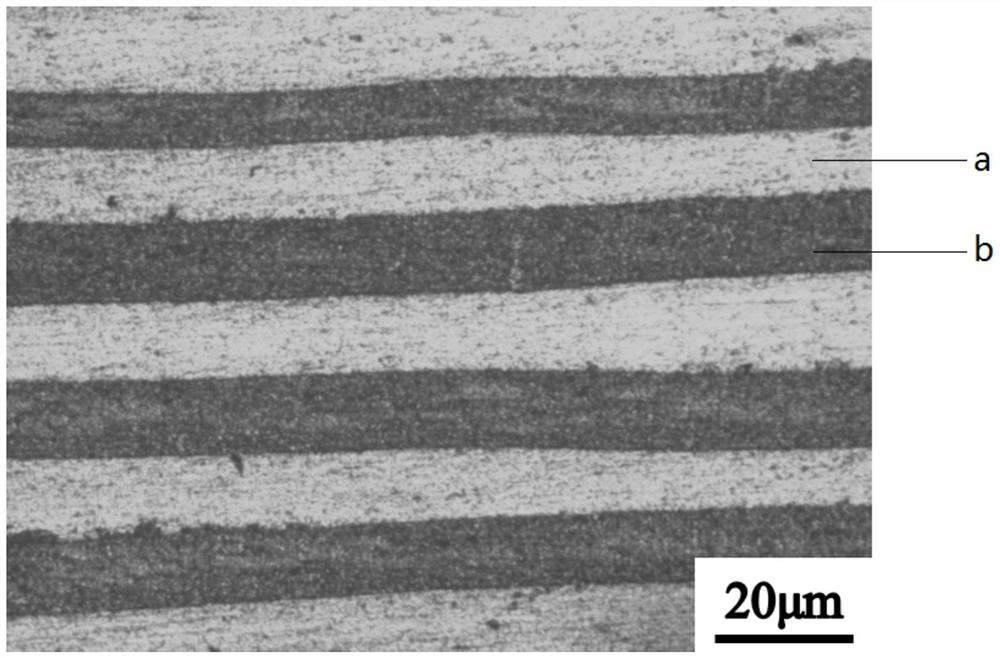

[0032] 3. Using the mixed powder obtained in step 2 as a raw material, a graphene microchip-reinforced alumin...

specific Embodiment approach 2

[0046] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the average sheet diameter of the graphene microsheets described in step one is 2 μm to 5 μm, and the average thickness is 5 to 10 nm; the average particle diameter of the aluminum metal powder is 10-20μm.

specific Embodiment approach 3

[0047] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the aluminum metal powder in step 1 is made of aluminum alloy; the aluminum alloy is Al-Si-Cu-Mg alloy, Al-Si- One of Mg-Be alloy, Al-Mg alloy, Al-Cu-Mg alloy, Al-Cu-Mn-Mg alloy, Al-Mn-Si-Cu alloy; in the Al-Si-Cu-Mg alloy Si is 4.5-6.5%, Cu is 1.6-2.2%, Mg is 0.45-0.65%; Mg in Al-Mg alloy is 3.5-5%; Cu in Al-Cu-Mg alloy is 0.5-5.8%, Mg is 0.3% ~3.5%; Cu in Al-Cu-Mn-Mg alloy is 3.8~4.9%, Mn is 0.3~9%, Mg is 1.5~1.8%; Si in Al-Si-Mg-Be alloy is 7.5~8.0%, Mg is 0.4-0.5%, Ti is 0.15-0.25%, Be is 0.15-0.20%; in Al-Mn-Si-Cu alloy, Mn is 4-5.2%, Cu is 0.6-0.8%, and Fe is 0.1-1.0%. , Si is 7.0 to 12%, and Ti is 0.1 to 1.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com