SiOC microspheres, preparation method thereof and application thereof in lithium ion battery negative electrode material

A microsphere, oil phase technology, applied in battery electrodes, secondary batteries, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing SiOC microspheres, comprising the following steps:

[0033] Mix polysiloxane, liquid pore former and catalyst to obtain oil phase; mix water and surfactant to obtain water phase;

[0034] adding the oil phase dropwise to the water phase to form an oil-in-water emulsion;

[0035] solidifying the oil phase in the oil-in-water emulsion to obtain a gel;

[0036] The gel was heat-treated under an inert atmosphere to obtain SiOC microspheres.

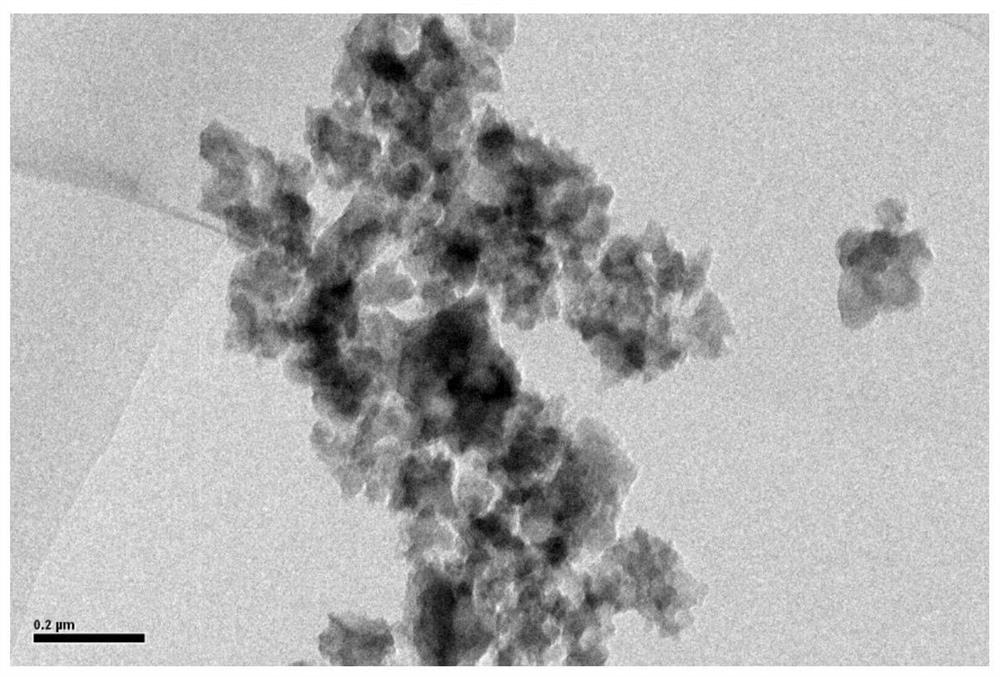

[0037] The method provided by the invention utilizes the emulsion template method combined with the liquid pore-forming process, uses liquid organic matter stable at room temperature as the pore-forming agent, and adopts a simple emulsion template method to prepare a microspherical SiOC negative electrode with high porosity, avoiding the use of hydrothermal polymerization, supercritical Complex processes such as drying and mechanical crushing and screening; the interior of the repeatedly ...

Embodiment 1

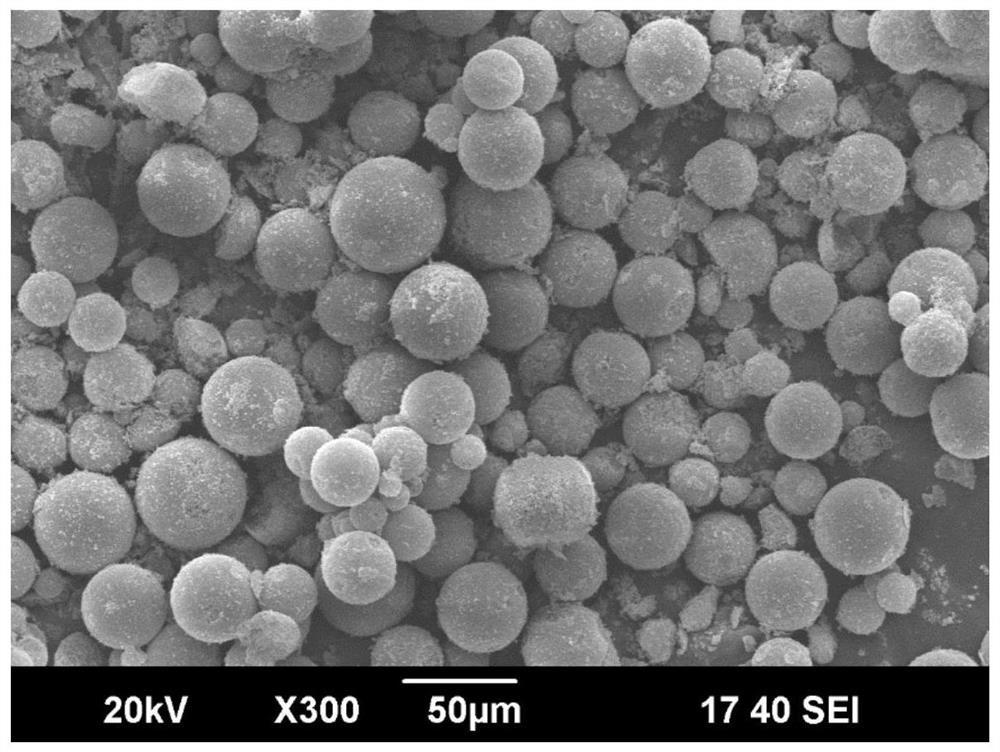

[0056] Mix hydrogen-containing polysiloxane and polydimethylsiloxane in a mass ratio of 1:4 by magnetic stirring for 30 minutes. Then, platinum divinyltetramethyl-disiloxane complex (accounting for 1% of the mass of hydrogen-containing polysiloxane) was added into the mixture, and stirred for 15 minutes to form an oil phase. In another beaker, 20 wt.% Tween 80 was added to deionized water to obtain an aqueous phase. The mass ratio of water and oil phase is 50:1. After the water phase and the oil phase are mixed uniformly, while stirring, the oil phase is added drop by drop into the water phase to form an oil-in-water emulsion. After stirring rapidly for 15 minutes, the emulsion was heated in an oven at 80 °C for 12 hours. During this process, the oil phase liquid rapidly gels and solidifies. The obtained gel was pyrolyzed at 1000° C. for 3 h in a flowing argon atmosphere to obtain SiOC microspheres.

Embodiment 2

[0057] Example 2: Mix polymethylphenylsiloxane and phenolic resin with a mass ratio of 1:2 by magnetic stirring for 30 minutes. Then, dibutyltin dilaurate (accounting for 0.5% of the mass of polymethylphenylsiloxane) was added into the mixture, and stirred for 15 minutes to form an oil phase. In another beaker, 10 wt.% Tween 20 was added to deionized water to obtain an aqueous phase. The mass ratio of water and oil phase is 30:1. After the water phase and the oil phase are mixed uniformly, while stirring, the oil phase is added drop by drop into the water phase to form an oil-in-water emulsion. After stirring rapidly for 15 minutes, the emulsion was irradiated with ultraviolet light for 6 hours. During this process, the oil phase liquid rapidly gels and solidifies. The obtained gel was pyrolyzed at 1100° C. for 3 h in a flowing argon atmosphere to obtain SiOC microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com