Wide-width continuous fiber thermoplastic resin preimpregnation equipment and production process thereof

A thermoplastic resin and continuous technology, which is applied in the field of wide-width continuous fiber thermoplastic resin pre-impregnation equipment and its production process, can solve the problems that fiber bundles cannot be completely seamlessly connected, increase the waste rate of unidirectional fabrics, etc., and achieve satisfactory results. The effect of splitting, improving the accuracy of tension detection, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

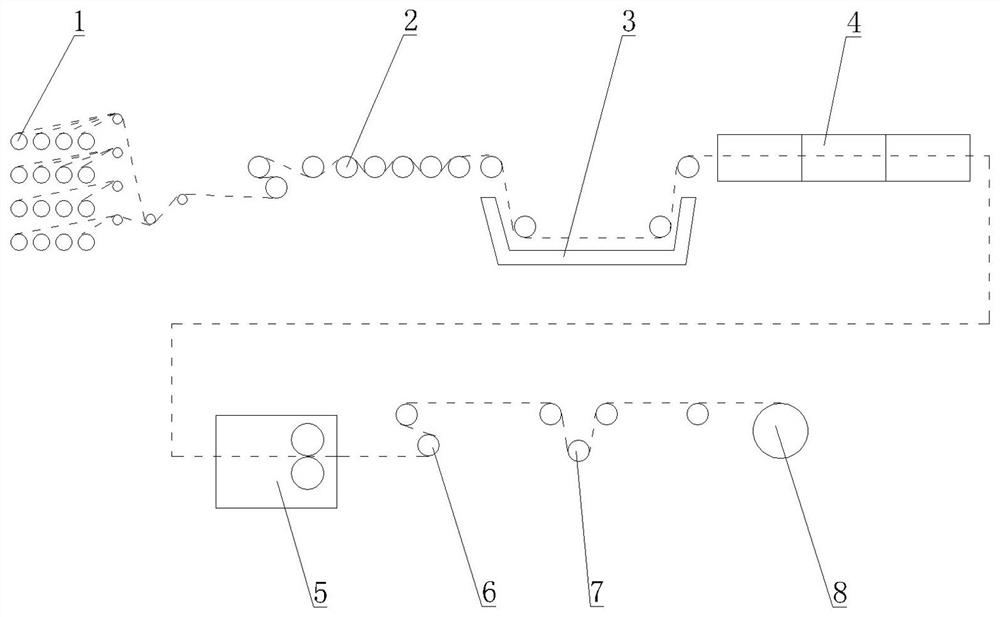

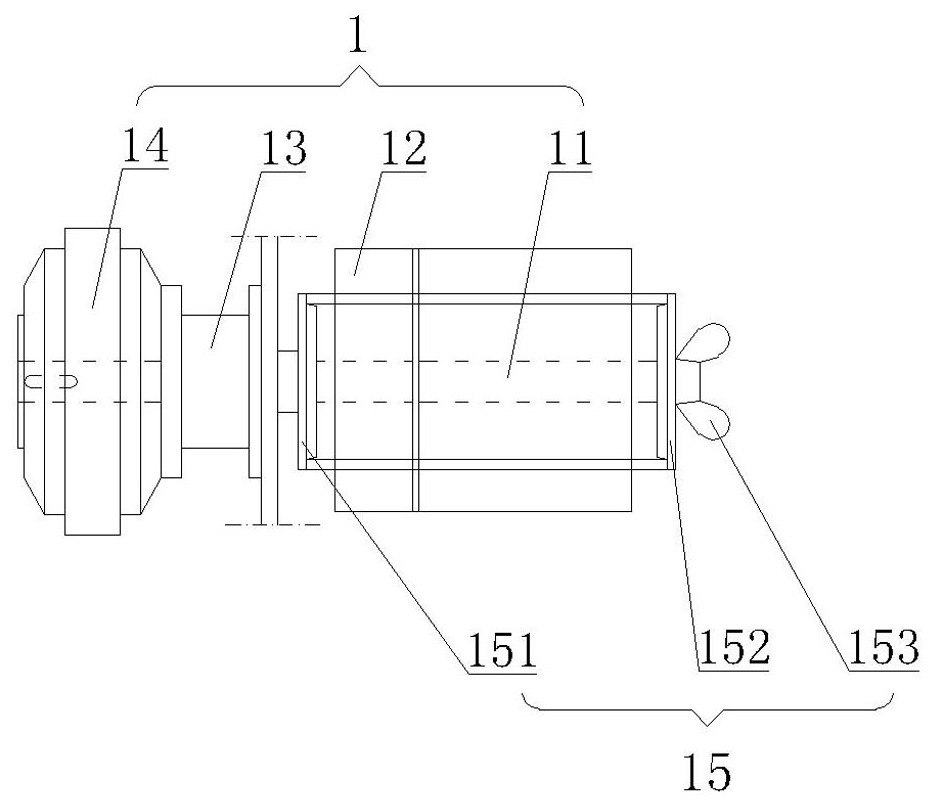

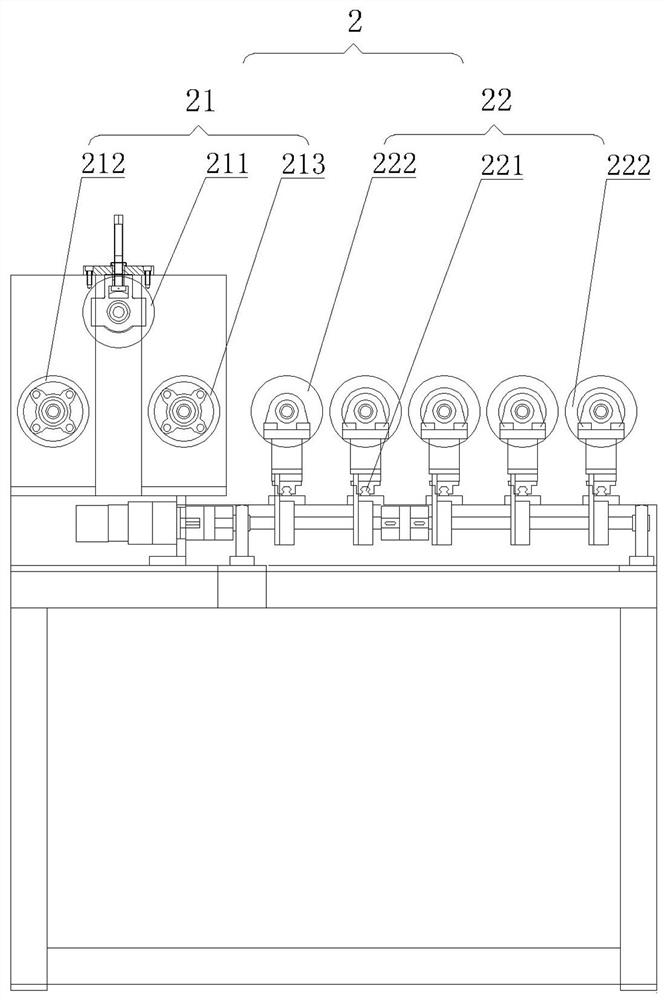

[0039] Example: as attached figure 1 - attached Figure 6 As shown, a wide-width continuous fiber thermoplastic resin prepreg equipment includes a fiber bobbin creel 1, the yarn output end of the fiber bobbin creel 1 is provided with a fiber splitting device 2, and the fiber splitting device 2 The yarn output end is provided with a mud tank device 3, and the fiber splitting device 2 includes a three-roller device 21 for generating and maintaining fiber tension. The yarn output end of the three-roller device 21 is horizontally provided with five shaking shafts 22, The shaking shafts 22 reciprocate perpendicularly to the fiber moving direction, and the two adjacent shaking shafts 22 move in opposite directions. The fibers referred to in the present invention can be selected from carbon fiber; glass fiber; aramid fiber and the like.

[0040] as attached image 3 , attached Figure 4 As shown, the three-roller device 21 includes a first roller 211 that can be adjusted up and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com