A kind of ultra-thin metal-organic framework nanosheet catalyst with lattice distortion, its preparation method and application

An ultra-thin metal and organic framework technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of unsatisfactory electrocatalytic water splitting oxygen evolution performance Problems such as not optimizing the position of the bimetallic energy band and not fully exposing the active site can achieve good catalytic stability, lower energy barrier, and low overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

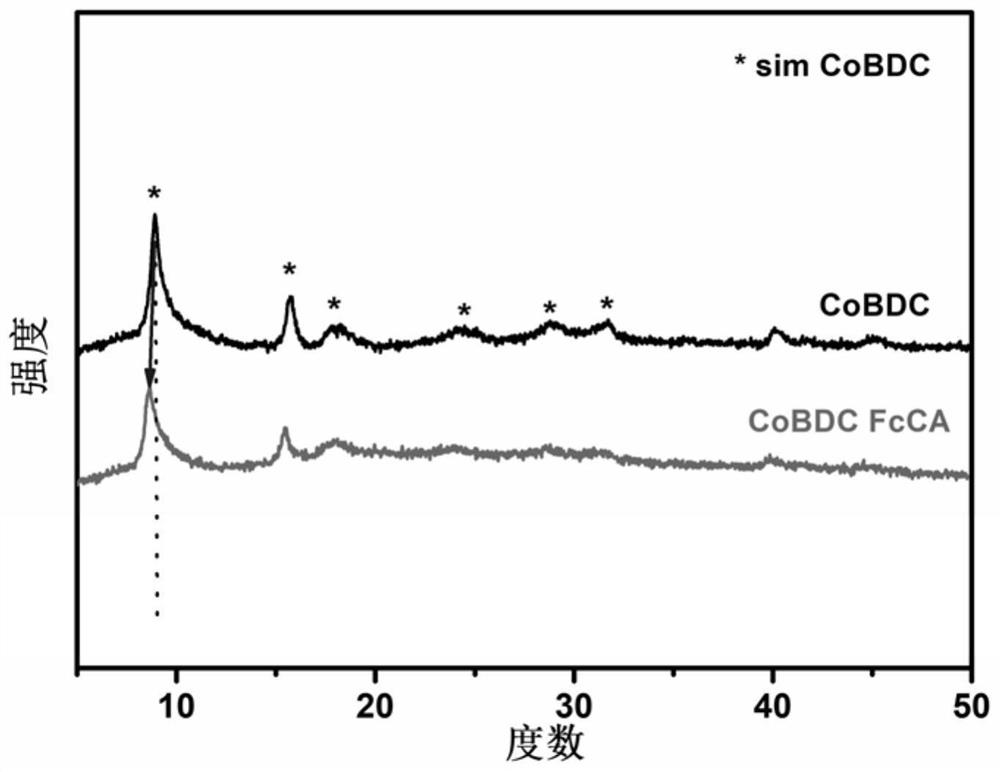

[0040] Synthesis of CoBDC FcCA catalyst: 166mg of terephthalic acid and 34.50mg of ferrocenecarboxylic acid were added to a mixed solution of N,N-dimethylformamide, absolute ethanol and deionized water (32mL:2mL:2mL), Subsequently, 238 mg of cobalt chloride hexahydrate was added to the above solution, and 1.5 mL of triethylamine was added rapidly at the same time, and magnetically stirred for 10 min. Then the above-mentioned mixed solution was transferred to a cell disruptor, and the strength of 700W was used for ultrasonic peeling for 500min. Then use absolute ethanol to wash several times, and use a 10000r / s high-speed centrifuge to separate the solid sample. Finally, the samples were dried under vacuum at room temperature for 12 h.

[0041] The catalyst after adding cobalt chloride and stirring is directly dried to obtain block CoBDC FcCA catalyst. What is finally obtained after sonication is an ultrathin CoBDC FcCA catalyst.

Embodiment 2

[0045] According to the preparation process of Example 1, the only difference is that 11.50 mg of ferrocenecarboxylic acid was added to obtain the CoBDC Fc0.05 catalyst.

Embodiment 3

[0047] According to the preparation process of Example 1, the only difference is that 23.00 mg of ferrocenecarboxylic acid was added to obtain the CoBDC Fc0.1 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com