A kind of segmental isobaric ammonia synthesis process

An ammonia synthesis and ammonia synthesis tower technology, which is applied in the field of ammonia synthesis, can solve the problems of low nitrogen and hydrogen utilization rate, low net value of exported ammonia, etc., and achieve the effects of reducing energy consumption, improving ammonia synthesis activity, and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

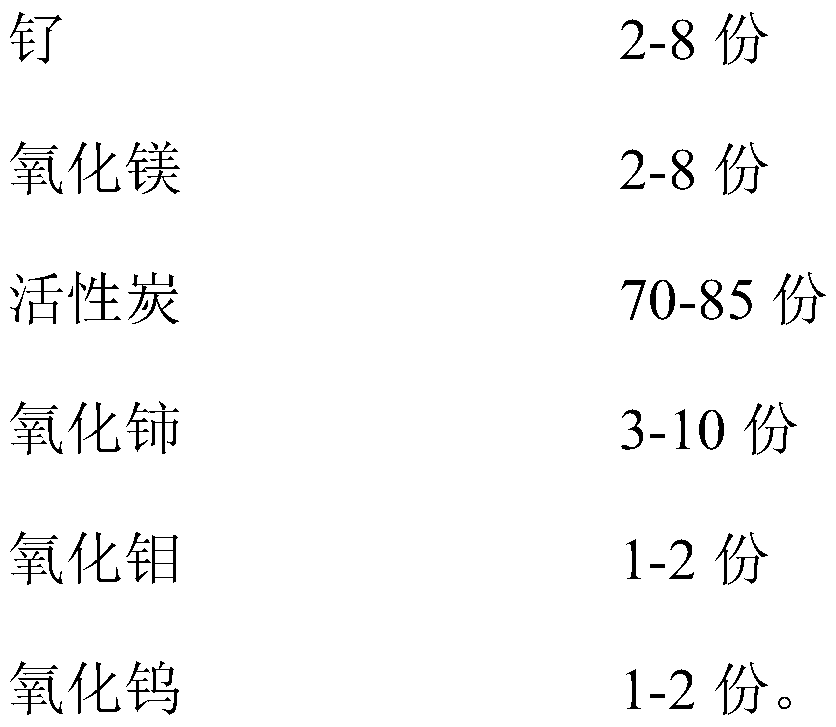

Method used

Image

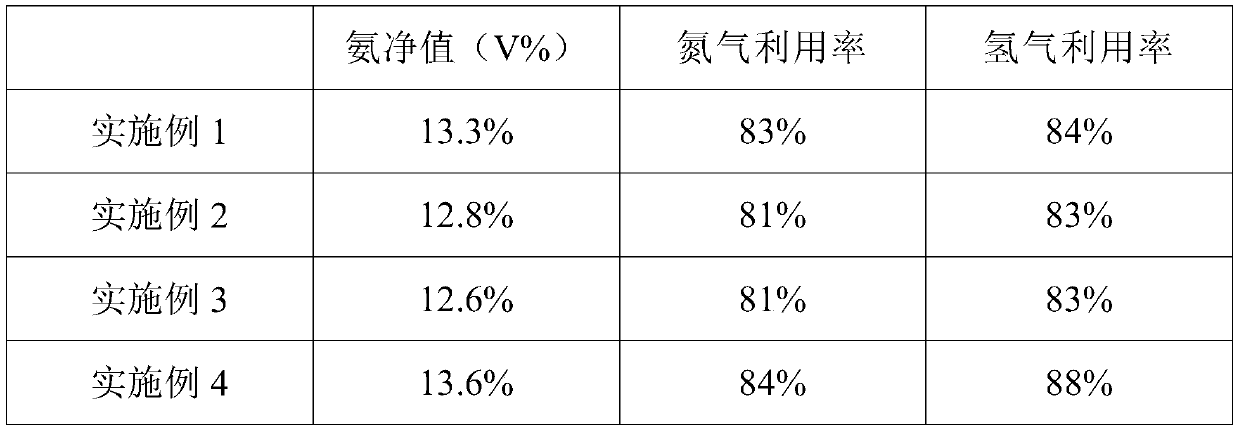

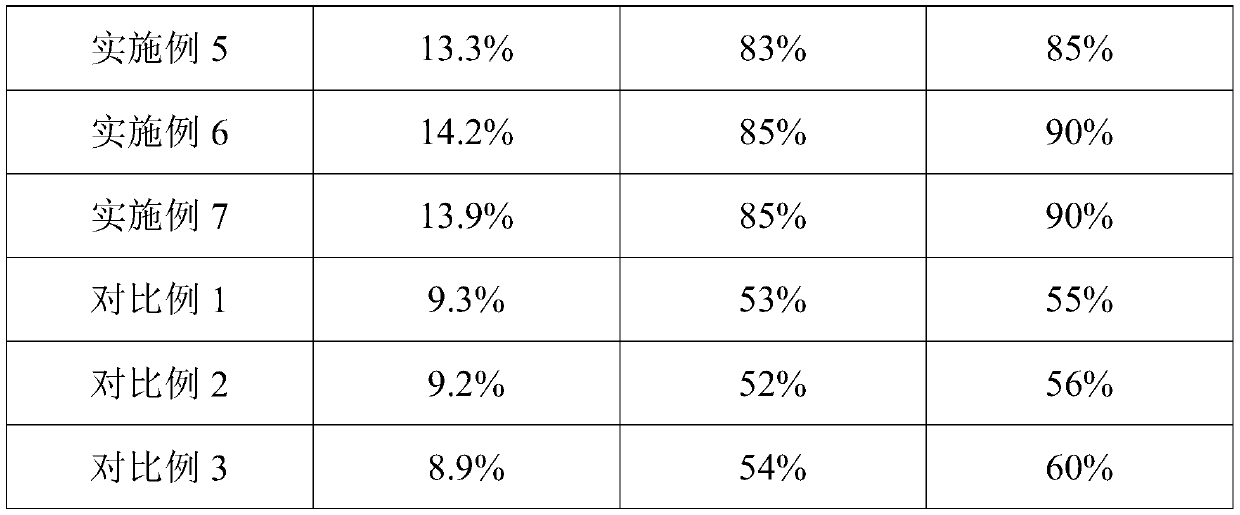

Examples

Embodiment 1

[0053] The present embodiment provides a segmented isobaric ammonia synthesis process, comprising the following steps:

[0054] 1) The raw material gas for ammonia synthesis is obtained after desulfurization, shift, desulfurization, decarburization and refining of shift gas, wherein S2 <10ppm, the molar ratio of hydrogen to nitrogen is 1.7:1;

[0055] 2) the above-mentioned synthetic ammonia raw material gas is 5000h with space velocity -1 The primary ammonia synthesis is carried out in the first ammonia synthesis tower filled with iron-based catalyst, the synthesis pressure of the primary ammonia synthesis is 6MPa, and the synthesis temperature is 450°C;

[0056] Wherein, the iron-based catalyst is Fe with a mass ratio of 2:2:1 3 o 4 , FeO and K 2 O is the active ingredient, with rare earth element oxides CeO and MgAl 2 o 4 As an auxiliary agent, the content of the active ingredient in the iron-based catalyst is 4wt%, the rare earth element oxide content is 0.1wt%, MgAl ...

Embodiment 2

[0065] The present embodiment provides a segmented isobaric ammonia synthesis process, comprising the following steps:

[0066] 1) The raw material gas for ammonia synthesis is obtained after desulfurization, shift, desulfurization, decarburization and refining of shift gas, wherein S2 <10ppm, the molar ratio of hydrogen to nitrogen is 1.5:1;

[0067] 2) The above-mentioned synthetic ammonia raw material gas is 6000h with space velocity -1 The primary ammonia synthesis is carried out in the first ammonia synthesis tower filled with iron-based catalyst, the synthesis pressure of the primary ammonia synthesis is 5MPa, and the synthesis temperature is 500°C;

[0068] Wherein, the iron-based catalyst is Fe with a mass ratio of 3:1:1 3 o 4 , FeO and K 2 O is the active ingredient, with rare earth element oxides CeO and MgAl 2 o 4 As an auxiliary agent, the content of the active ingredient in the iron-based catalyst is 2wt%, the rare earth element oxide content is 0.2wt%, MgAl ...

Embodiment 3

[0077] The present embodiment provides a segmented isobaric ammonia synthesis process, comprising the following steps:

[0078] 1) The raw material gas for ammonia synthesis is obtained after desulfurization, shift, desulfurization, decarburization and refining of shift gas, wherein S2 <10ppm, the molar ratio of hydrogen to nitrogen is 2.5:1;

[0079] 2) the above-mentioned synthetic ammonia raw material gas is 4000h with space velocity -1 The primary ammonia synthesis is carried out in the first ammonia synthesis tower filled with iron-based catalyst, the synthesis pressure of the primary ammonia synthesis is 7MPa, and the synthesis temperature is 430°C;

[0080] Wherein, the iron-based catalyst is Fe with a mass ratio of 2.5:1.5:1 3 o 4 , FeO and K 2 O is the active component, with rare earth element oxides CeO and MgAl 2 o 4 As an auxiliary agent, the content of the active ingredient in the iron-based catalyst is 3wt%, the rare earth element oxide content is 0.15wt%, M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com