Ammonia separation device and method

A technology of ammonia separation and thermal evaporation, which is applied in the direction of ammonia preparation/separation, sustainable manufacturing/processing, climate sustainability, etc. It can solve the problems of limiting the increase of production capacity, increasing the system circulation, and consuming large refrigeration work. Achieve the effects of easy operation, increased ammonia production, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

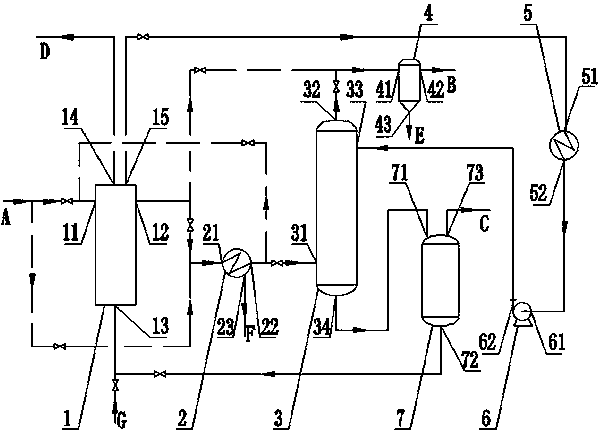

[0021] Ammonia separation device designed by the present invention (abbreviation device, see figure 1 , figure 2 , in the figure, the solid arrow line is the device connection structure in the production stage, and the dotted arrow line is the device connection structure in the production preparation stage), which is characterized in that the device mainly includes a heat exchange evaporator 1, a gas cooler 2, and an absorption tower 3 , gas-liquid separator 4, absorbent cooler 5, high-pressure pump 6 and flash evaporator 7, as well as connecting pipelines and two sets of process switching valves.

[0022] The heat exchange evaporator 1 of the device of the present invention is designed with five process nozzles, which are respectively a hot flow inlet 11, a hot flow outlet 12, a cold flow inlet 13, a cold flow gas phase outlet 14 and a cold flow liquid phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com