Method for separating ammonia

An absorbent and desorption technology, applied in the field of ammonia separation and production technology for separating ammonia and synthesizing ammonia, can solve the problems of increasing the consumption of raw coal, increasing the amount of circulation, wasting energy, etc. net worth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

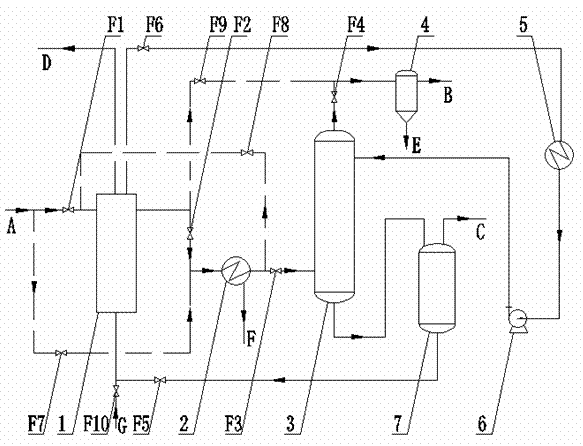

[0012] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

[0013] The method for separating ammonia designed by the present invention (abbreviation method, see figure 1 ,exist figure 1 Among them, the solid arrow line is the process flow of the production stage, and the dotted arrow line is the process flow of the production preparation stage). This method includes the production preparation stage (catalyst heating and reduction stage) and production stage (ammonia separation stage), and the process flow is as follows:

[0014] The production preparation stage of the method of the present invention refers to the stage of temperature raising and reduction of the catalyst that needs to be carried out before normal production. This stage is to use the hydrogen in the cycle gas to reduce the catalyst (the main component is iron oxide) in the synthesis tower to a catalyst with catalytic activity (α-Fe), and it is necessar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com