Automatic jasmine tea processing production line

A technology for jasmine tea and production line, which is applied in the directions of tea, tea spice, tea treatment before extraction, etc., can solve the problems of lack of high-efficiency automatic production line, cumbersome jasmine tea production process, etc., so as to reduce intervention, mix flowers evenly, and ensure cleanliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

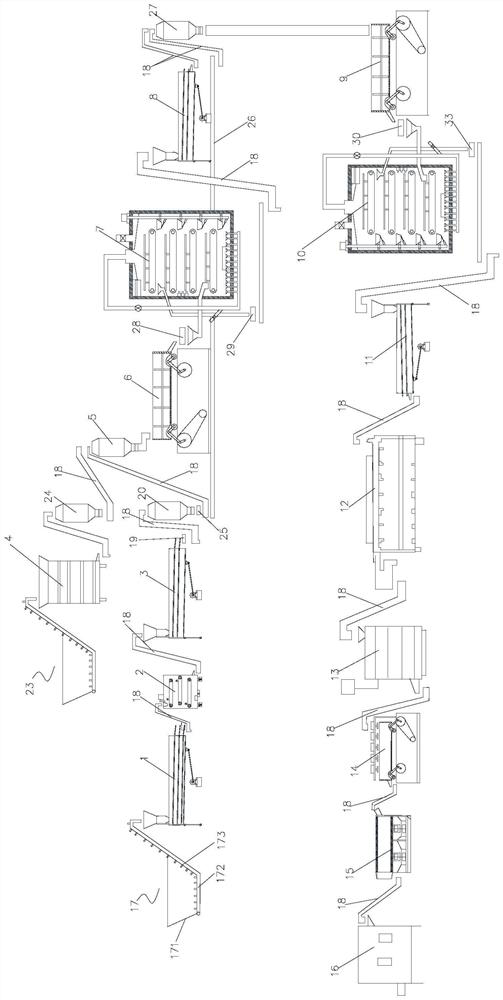

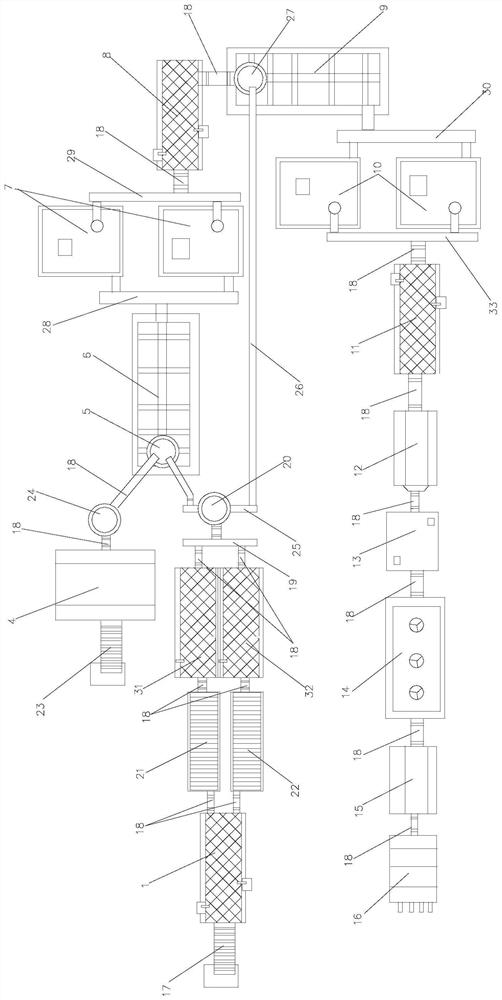

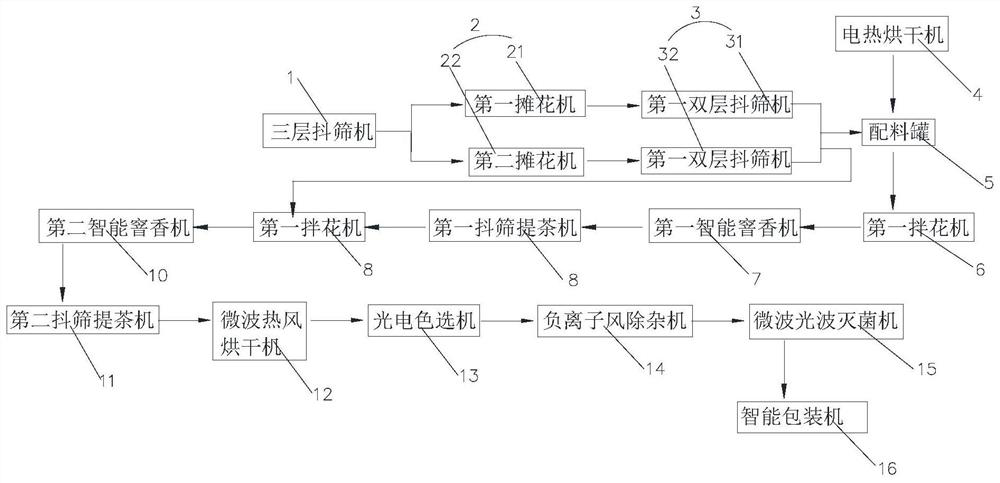

[0030] Examples such as image 3 Shown, a kind of automatic processing production line of jasmine tea, is used for realizing the automation of jasmine tea, continuous processing. It is mainly composed of the following equipment connected by the conveying device, including three-layer shaking screen machine 1, flower spreading machine 2, double-layer shaking screen machine 3, electric heating dryer 4, the first flower mixing machine 6, and the first intelligent scenting machine Machine 7, the first shaking and sieving tea machine 8, the second flower mixing machine 9, the second intelligent scenting machine 10, the second shaking and sieving tea machine 11, microwave dryer 12, photoelectric color sorter 13, negative ion wind Impurity remover 14, microwave light wave sterilizer 15, intelligent packaging machine 16.

[0031] The following is a specific description of the connection combination relationship of each equipment in this production line and the specific structure of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com