Device for producing connecting lines with terminals

A technology for connecting wires and terminals, applied in the field of motor vehicle parts processing equipment, can solve the problems of reducing production cost, low processing efficiency, affecting processing efficiency, etc., and achieves the effects of convenient operation and control, improved use effect, and simple and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

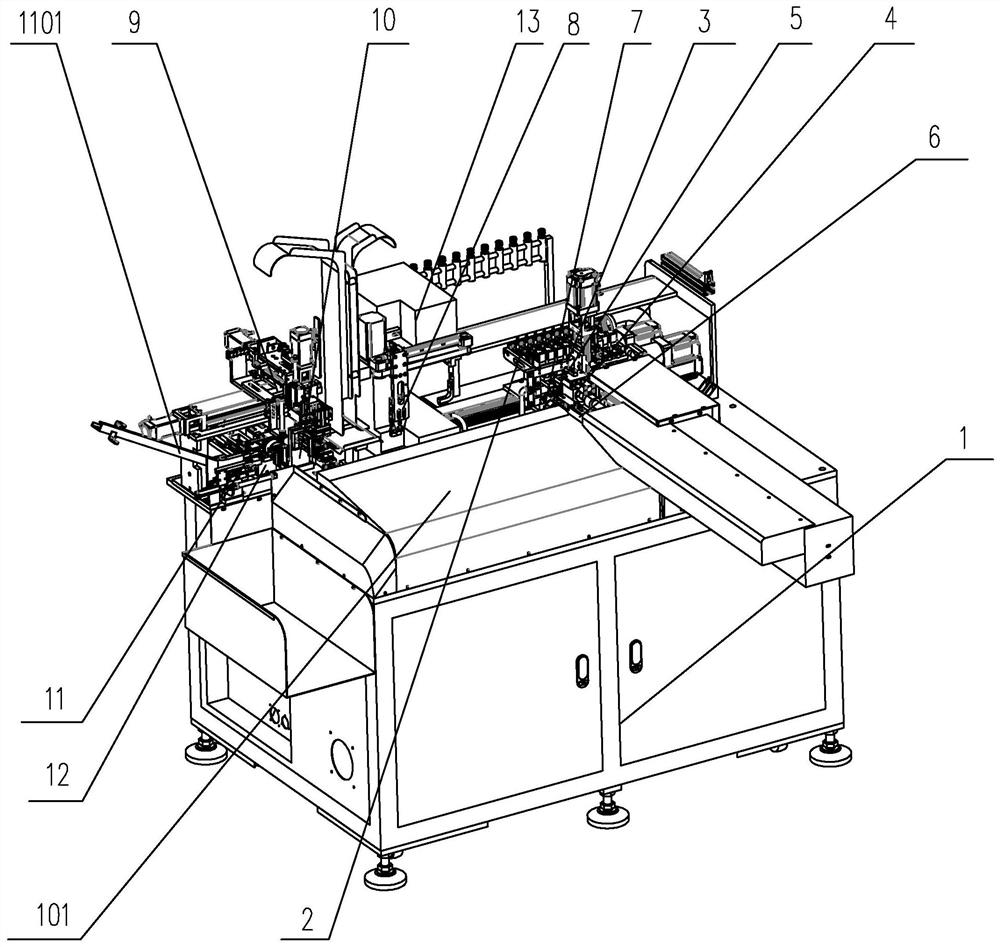

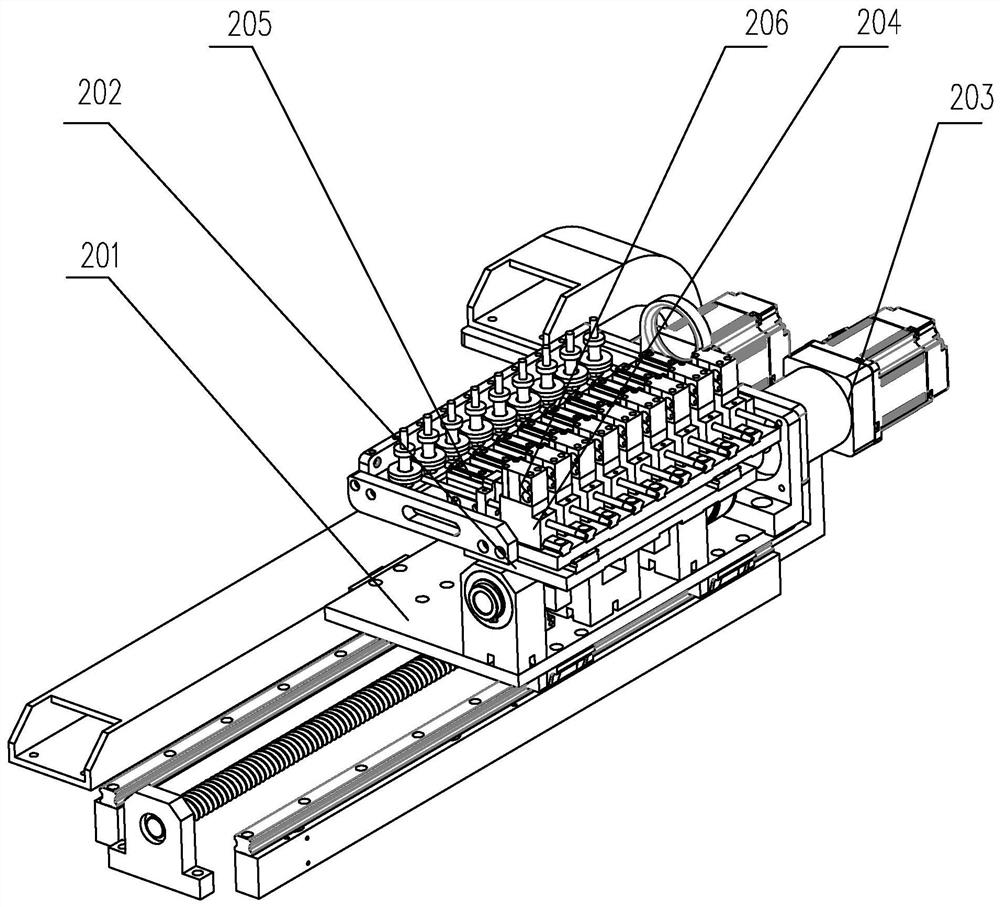

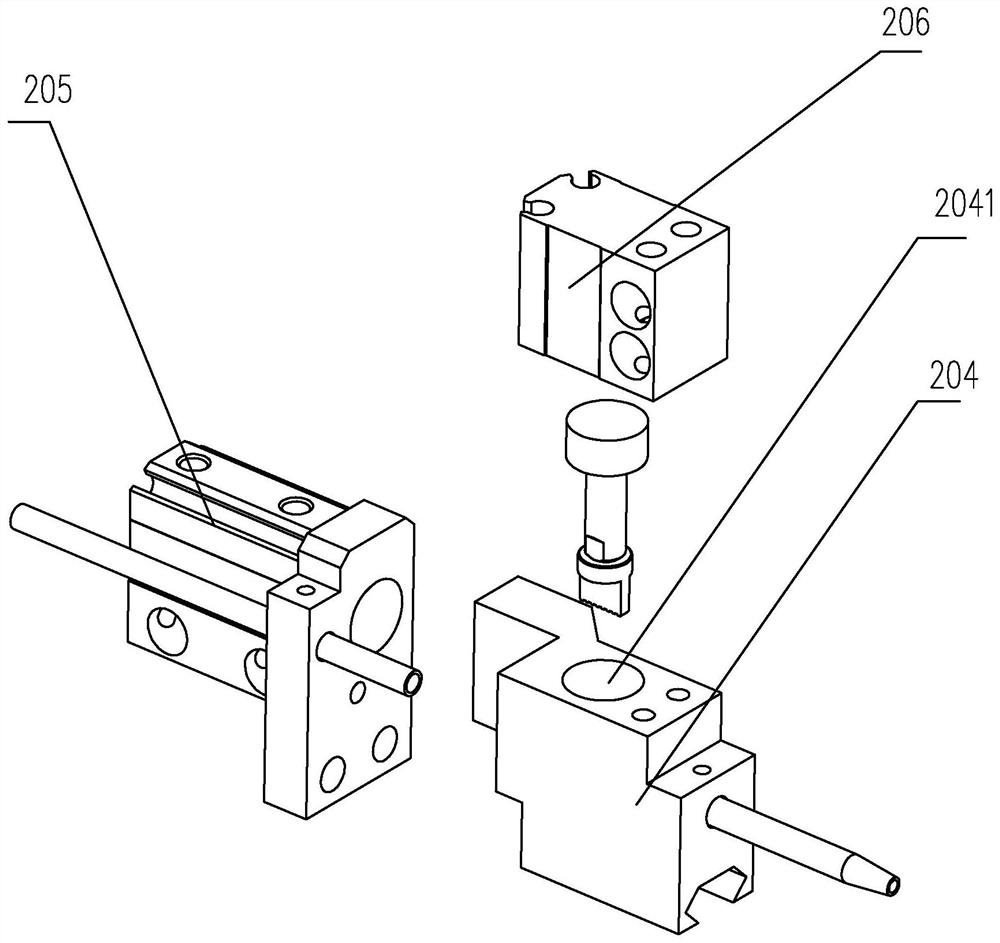

[0048] Embodiments of the present invention for the production of equipment for connecting wires with terminals are as Figure 1 to Figure 12 As shown: including a frame 1, the frame 1 is sequentially provided with a feeding mechanism 2, a terminal installation mechanism 13, a positioning seat 10, a loading support 12 and a feeding track 1101, and the corresponding feeding mechanism 1101 is on the frame 1 The position of the mechanism 2 is provided with a cutting knife seat 305, a ring cutter seat 303, a stripping knife seat 307, a lift frame 3 and a cutting cylinder 301 for driving the lift frame 3 to lift, and the lift frame 3 is provided with a ring cutter 302, a cutting knife 304 and a stripping knife 306, a ring cutting channel is formed between the ring cutting knife 302 and the ring cutting knife seat 303, a cutting channel is formed between the cutting knife 304 and the cutting knife seat 305, A stripping channel is formed between the stripping knife 306 and the stripp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com