4A type molecular sieve modified photocuring pipeline repair lining material and processing technology

A pipeline repair and processing technology, applied in the direction of pipes/pipe joints/fittings, pipe components, layered products, etc., can solve problems such as production process obstacles, uneven mixing, etc., achieve extreme physical properties, improve curing rate, design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A 4A-type molecular sieve-modified light-cured pipeline repair lining material and its processing technology in this embodiment are characterized in that the light-cured pipeline repair lining material is composed of an anti-ultraviolet film, a resin isolation film, a vacuum introduction isolation film, glass Fiber axial braid, waterproof inner lining braid and high light transmittance film are covered in sequence, arranged according to the ring-mounted circular pipe, and its cross-section is from outside to inside: anti-ultraviolet film, resin isolation film, and vacuum introduction isolation film , glass fiber axial braid, waterproof lining braid and high light transmittance film;

[0038] The glass fiber axial braid is impregnated with a hyperbranched epoxy photocurable resin mother liquor;

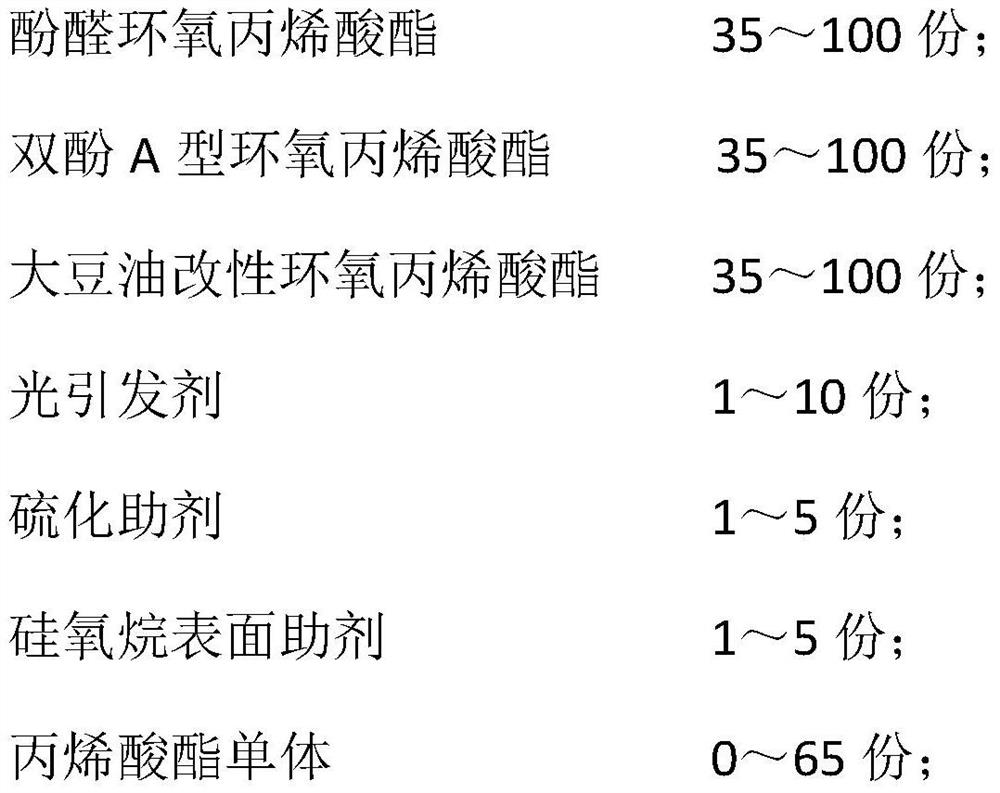

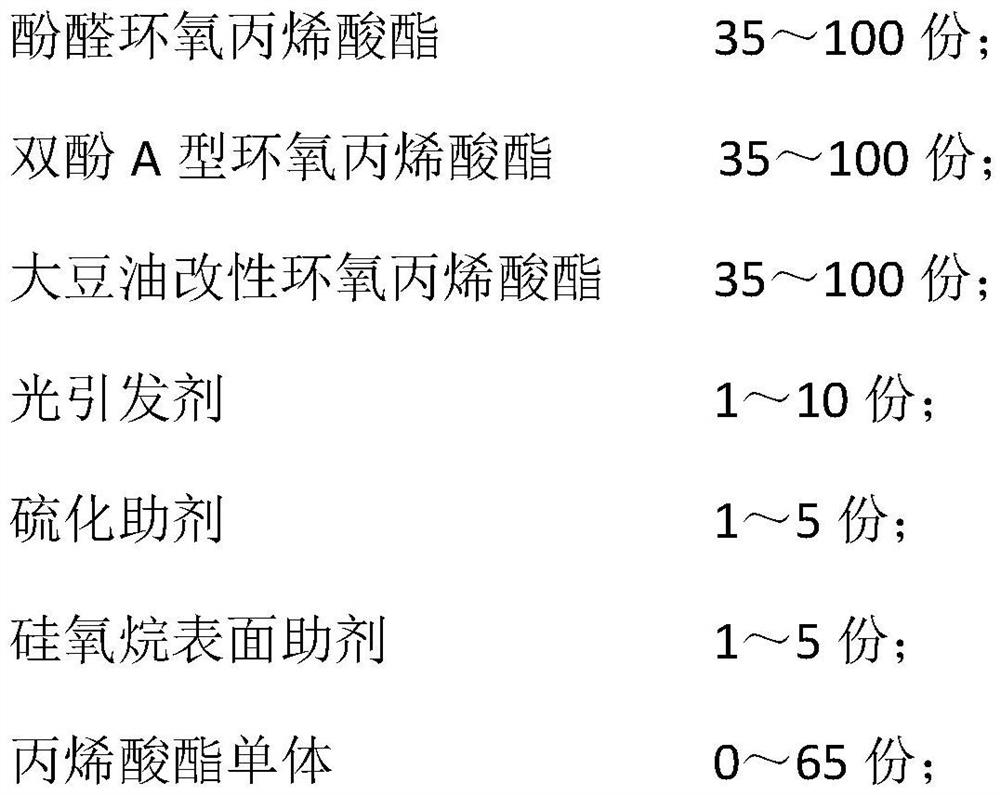

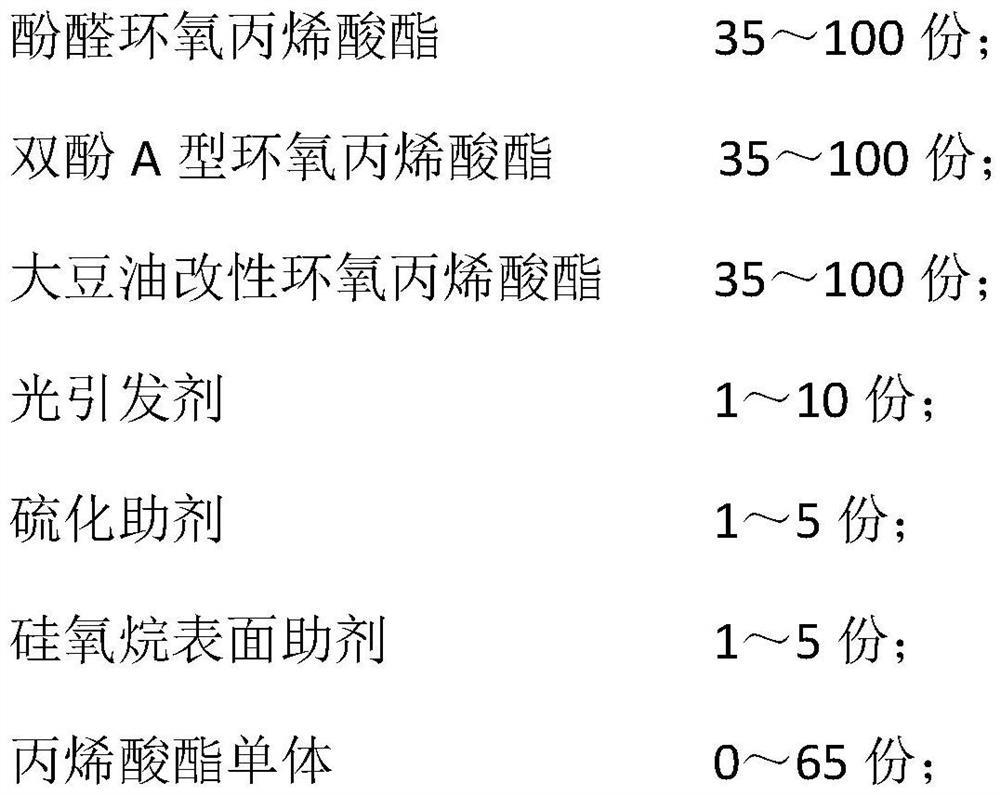

[0039] Wherein, the hyperbranched epoxy photocurable resin mother liquor comprises the following components in parts by weight:

[0040]

[0041] Add the above components in...

Embodiment 2

[0045] A 4A-type molecular sieve-modified light-curing pipeline repair lining material and its processing technology in this embodiment, wherein the processing technology of the light-curing pipeline repair lining material includes the following specific steps:

[0046](a1) Molecular sieve spraying: Cover the high light transmittance film, waterproof lining braid and glass fiber axial braid sequentially from the inside to the outside. The outer surface of the glass fiber axial braid is sprayed with molecular sieve;

[0047] (a2) Molecular sieve lining: After the molecular sieve is uniformly sprayed and dried, the vacuum is introduced into the isolation film, resin isolation film and UV protection film, and the glass fiber axial braid is coated sequentially from the inside to the outside to obtain a dry molecular sieve lining. material;

[0048] (a3) resin mother liquor preparation: by weight parts, with novolac epoxy acrylate, bisphenol A type epoxy acrylate, soybean oil modi...

Embodiment 3

[0055] A 4A-type molecular sieve-modified light-curing pipeline repair lining material and its processing technology in this embodiment, wherein the processing technology of the light-curing pipeline repair lining material includes the following specific steps:

[0056] (b1) resin mother liquor preparation: by weight parts, with novolac epoxy acrylate, bisphenol A type epoxy acrylate, soybean oil modified epoxy acrylate photoinitiator, vulcanization auxiliary agent, siloxane surface auxiliary agent and acrylate monomer into a mixing container, and fully mixed to obtain a hyperbranched epoxy photocurable resin mother liquor, which is ready for use;

[0057] (b2) Resin mother liquor preparation: add molecular sieves to the hyperbranched epoxy photocurable resin mother liquor obtained in step (b1), and fully mix to obtain a hyperbranched epoxy photocurable resin modified mother liquor;

[0058] (b3) Impregnation of the glass fiber axial braid: at 20°C, place the glass fiber axial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com