Mesoporous bioactive glass/polylactic acid-glycolic acid copolymer composite microspheres and preparation method and application thereof

A technology of glycolic acid copolymer and bioactive glass, which is applied in the field of PLGA microspheres, can solve the problems of lack of osteoinductive ability and limit the application of composite microspheres, and achieve good osteoinductive ability, good osteoconductivity, and preparation process easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

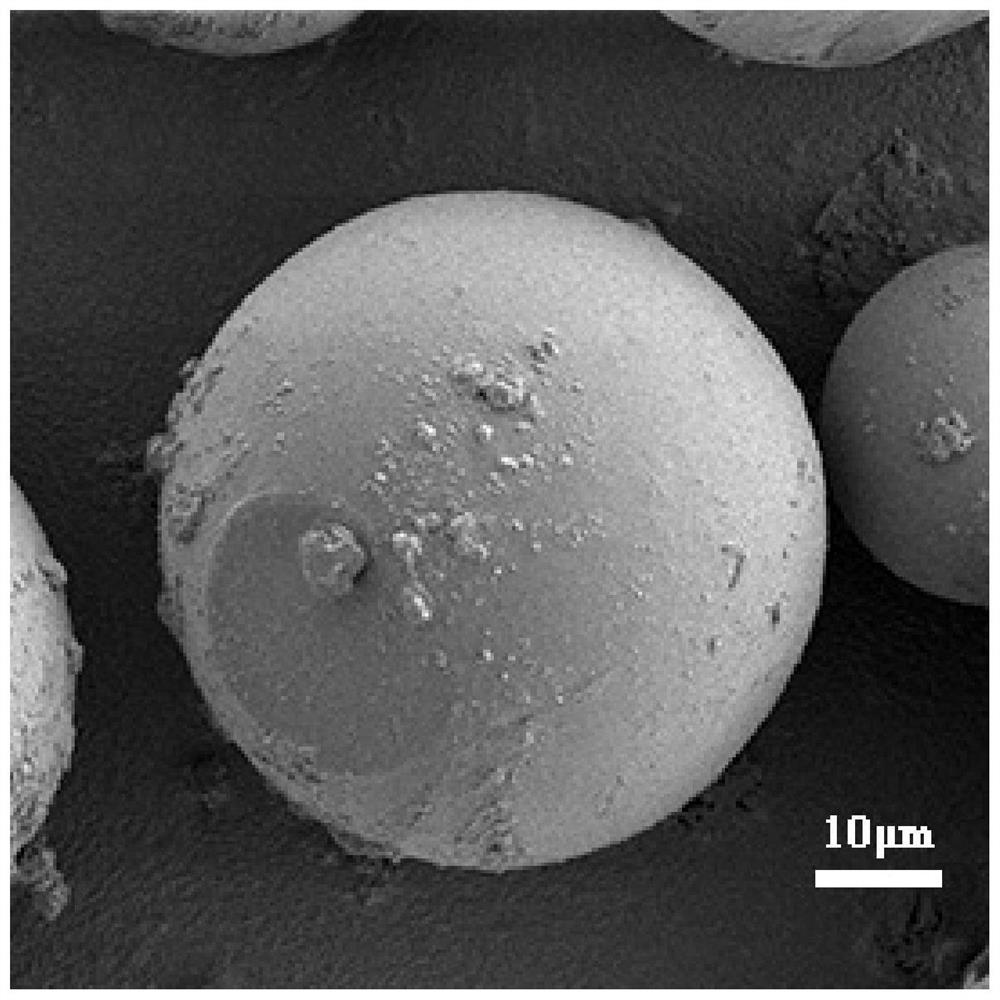

[0035] A kind of mesoporous bioactive glass / polylactic acid-glycolic acid copolymer composite microsphere, its preparation method is as follows:

[0036] (1) Preparation steps of mesoporous bioactive glass powder:

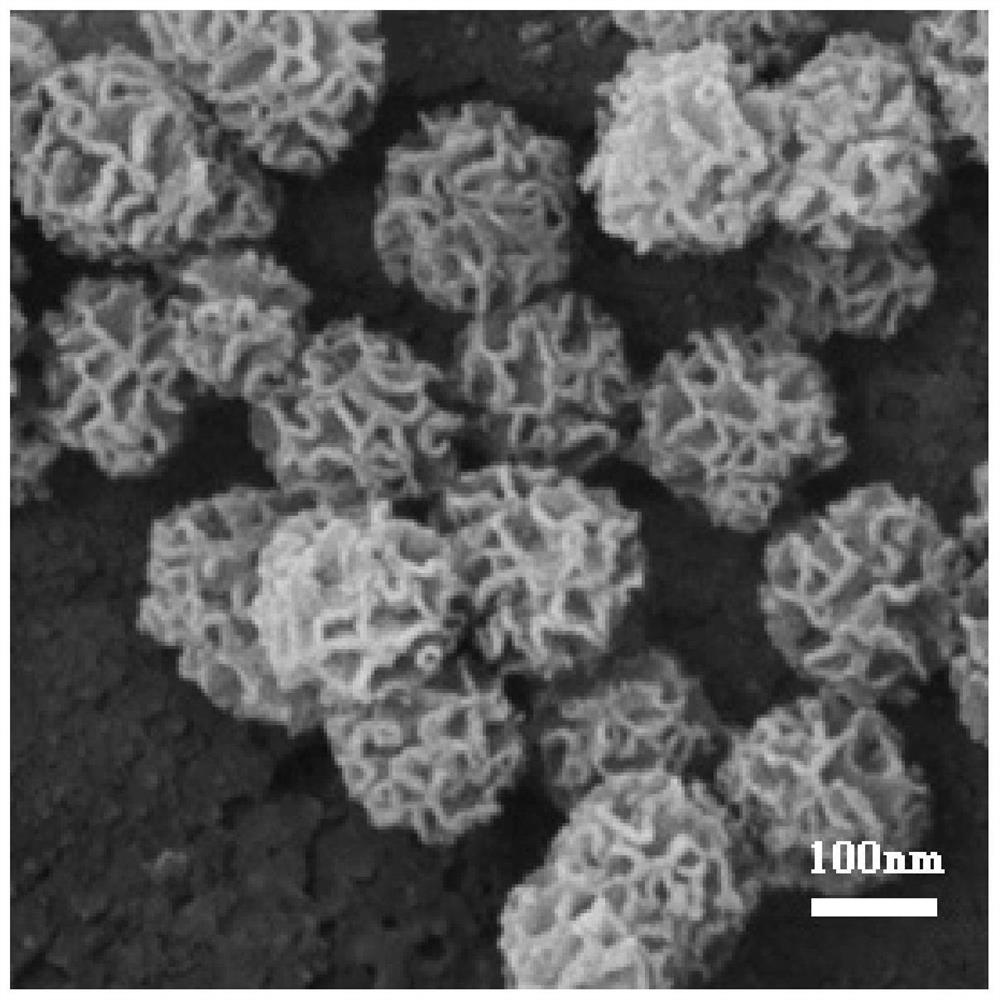

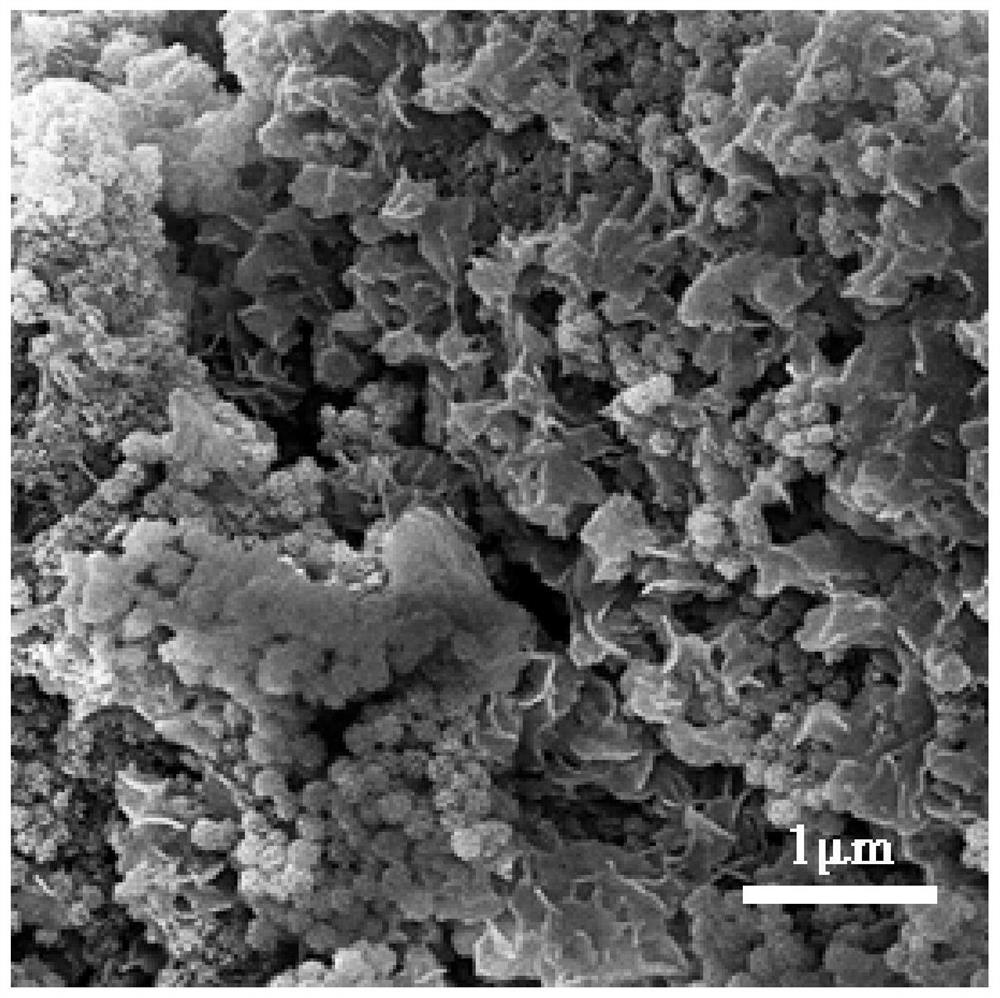

[0037] Mesoporous bioactive glass is prepared by microemulsion technology combined with sol-gel template method. The specific synthesis process is as follows: First, 12g of cetyltrimethylammonium bromide (CTAB) is added to 108ml of deionized water, and heated in a 60°C water bath. Stir in the pot until completely dissolved; then add 0.36ml triethanolamine (TEA), then add 2.510g calcium nitrate tetrahydrate and stir until completely dissolved to obtain an aqueous phase solution; then add 12mL tetraethyl orthosilicate (TEOS), 0.921mL triphosphate Mix ethyl ester (TEP) and 48mL cyclohexane evenly to form an oil phase mixture; then use a syringe pump to add the oil phase solution to the water phase solution at a speed of 1.5ml / min, and condense and reflux in a water ba...

Embodiment 2

[0041] A kind of mesoporous bioactive glass / polylactic acid-glycolic acid copolymer composite microsphere, its preparation method is as follows:

[0042] (1) Preparation steps of mesoporous bioactive glass powder:

[0043] Mesoporous bioactive glass is prepared by microemulsion technology combined with sol-gel template method. The specific synthesis process is as follows: First, 8g of cetyltrimethylammonium bromide (CTAB) is added to 108ml of deionized water, and heated in a 60°C water bath. Stir in the pot until completely dissolved; then add 0.36ml triethanolamine (TEA), then add 2.510g calcium nitrate tetrahydrate and stir until completely dissolved to obtain an aqueous phase solution; then add 12mL tetraethyl orthosilicate (TEOS), 0.921mL triphosphate Mix ethyl ester (TEP) and 48mL cyclohexane evenly to form an oil phase mixture; then use a syringe pump to add the oil phase solution to the water phase solution at a speed of 1.5ml / min, and condense and reflux in a water bat...

Embodiment 3

[0047] A kind of mesoporous bioactive glass / polylactic acid-glycolic acid copolymer composite microsphere, its preparation method is as follows:

[0048] (1) Preparation steps of mesoporous bioactive glass powder:

[0049] Mesoporous bioactive glass is prepared by microemulsion technology combined with sol-gel template method. The specific synthesis process is as follows: First, 15g of cetyltrimethylammonium bromide (CTAB) is added to 108ml of deionized water, and heated in a 60°C water bath. Stir in the pot until completely dissolved; then add 0.36ml triethanolamine (TEA), then add 2.510g calcium nitrate tetrahydrate and stir until completely dissolved to obtain an aqueous phase solution; then add 12mL tetraethyl orthosilicate (TEOS), 0.921mL triphosphate Mix ethyl ester (TEP) and 48mL cyclohexane evenly to form an oil phase mixture; then use a syringe pump to add the oil phase solution to the water phase solution at a speed of 1.5ml / min, and condense and reflux in a water ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com