Exhaust SCR denitration purification silencer for marine diesel engine

A marine diesel engine and muffler technology, which is applied in exhaust gas treatment, exhaust devices, machines/engines, etc., can solve the inconvenience of maintenance and disassembly of the exhaust reaction catalyst carrier, occupy a large amount of space on the ship, and have poor exhaust gas treatment and noise reduction effects and other problems, to achieve the effect of saving initial installation cost, saving installation space and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

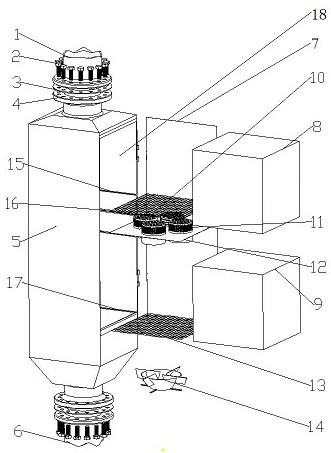

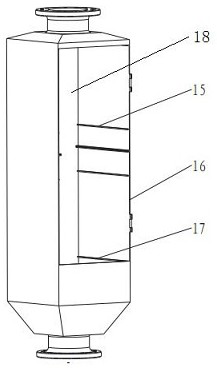

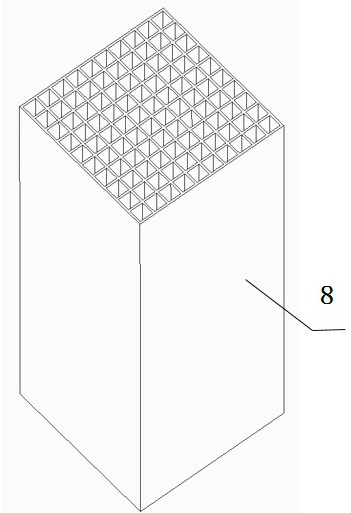

[0021] Example: such as Figure 1 to Figure 5 As shown, a marine diesel engine exhaust SCR denitrification purification muffler includes a cuboid housing 5, the two ends of the housing 5 are provided with an intake pipe 6 and an exhaust pipe 1, and the inner hollow part of the housing 5 is provided with a catalytic converter. The catalyst carrier, the connection between the housing 5 and the catalyst carrier adopts a drawer structure, one side of the housing 5 is opened and set as a maintenance port 18 to facilitate the placement and removal of the catalyst carrier, and the open part of the housing 5 is provided with an openable The cover plate is set as the maintenance cover plate 7, the inside of the catalyst carrier is a honeycomb structure, and an appropriate amount of reaction catalyst is attached to the surface of the inner hole of the catalyst carrier; the inner wall of the side wall of the open part of the housing 5 is provided with a three-layer raised structure set as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com