Silicon removal agent and silicon removal and hardness removal sewage treatment system and method

A sewage treatment method and technology of sewage treatment system, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of low soluble silicon removal efficiency, high reaction temperature requirements, The gel is not easy to settle and other problems, so as to achieve the effect of enhancing the flocculation and separation effect, increasing the specific gravity of the floc and prolonging the storage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

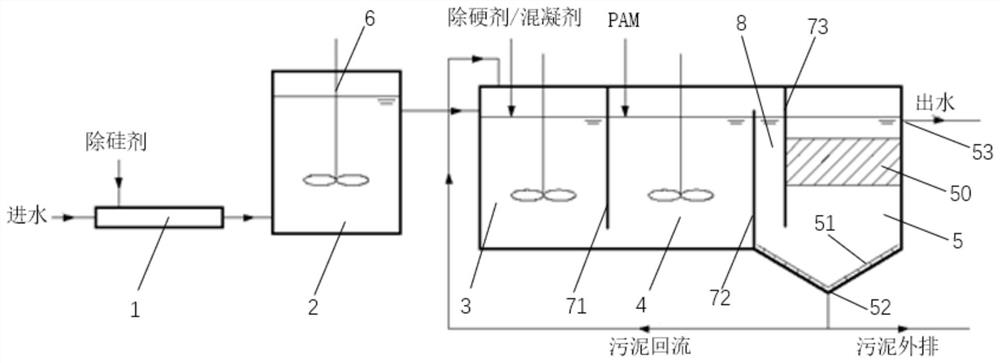

Method used

Image

Examples

Embodiment 1

[0085] For a sewage treatment plant reverse osmosis concentrated water containing silicon 156mg / L (SiO 2 ), hardness 50mg / L, adopt technical solution of the present invention to process:

[0086] S1. Add 200 mg / L silicon remover through the pipeline mixer; in the silicon remover, the mass fraction of the active agent is 76%, the modifier is 20%, and the stabilizer is 4%, so that the silicon remover is mixed with the waste water; And wherein the active agent is sodium metaaluminate, the modifier is calcium oxide powder, and the stabilizer is sodium hydroxide;

[0087] S2. After mixing evenly, enter the silicon removal tank, adjust the pH to 9, stir and react at 40°C, and the residence time is 10min;

[0088] S3, the reacted water enters the coagulation tank, and 50mg / L of ferric chloride is added as a coagulant, and the residence time is 15min;

[0089] S4. The reacted water enters the flocculation tank through the bottom of the first partition, and 2mg / L PAM is added as a fl...

Embodiment 2

[0100] For a high-density pool effluent containing silicon 90mg / L (SiO 2 ), hardness 560mg / L, adopt technical solution of the present invention to process:

[0101] S1. Add 100 mg / L silicon remover through the pipeline mixer. In the silicon remover, the mass fraction of the active agent is 72%, the modifier is 25%, and the stabilizer is 3%, so that the silicon remover is mixed with the waste water; In addition, sodium metaaluminate is used as the active agent, and aluminum chloride accounting for 3 wt% of sodium metaaluminate is added to the sodium metaaluminate; calcium oxide powder is used as the modifier; sodium hydroxide is used as the stabilizer;

[0102] S2. After mixing evenly, enter the silicon removal tank, adjust the pH to 8.5, stir and react at 30°C, and the residence time is 10min;

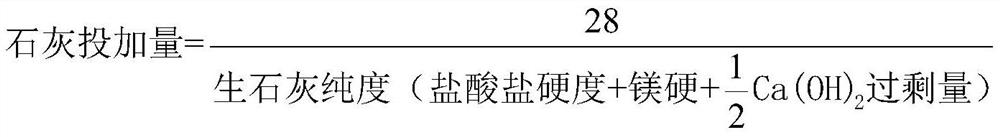

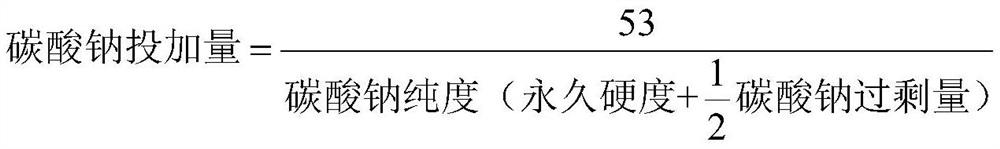

[0103] S3. After the reaction, the water enters the coagulation tank, and 300mg / L lime and 300mg / L sodium carbonate are added as the hardening agent, and the pH is adjusted to 10.4, a...

Embodiment 3

[0115] For a certain high-density pool effluent containing silicon 70mg / L (SiO 2 ), hardness 560mg / L, adopt technical solution of the present invention to process:

[0116] S1. Add 100 mg / L silicon remover through the pipeline mixer, and mix the silicon remover with wastewater; in the silicon remover, the mass fraction of the active agent is 85%, the modifier is 10%, and the stabilizer is 5%; The desiliconization agent is mixed with waste water; wherein the active agent is sodium metaaluminate, and aluminum sulfate accounting for 5wt% of sodium metaaluminate is added to the sodium metaaluminate; the modifier is magnesium oxide powder; the stabilizer is sodium hydroxide ;

[0117] S2. After mixing evenly, enter the silicon removal tank, adjust the pH to 10.5, stir and react at 20°C, and the residence time is 30min;

[0118] S3. After the reaction, the water enters the coagulation tank, add 300mg / L lime and 300mg / L sodium carbonate as the hardening agent, adjust the pH to 11, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com