Novel aluminium alloy floor manufacturing method

A manufacturing method and technology of aluminum alloy, applied in the field of floor manufacturing, can solve the problems of reducing the thermal conductivity of aluminum alloy floors, deformation and bending of aluminum alloy floors, and increasing energy consumption of floor heating equipment, etc. The effect of convenient maintenance and secondary use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Aiming at the deficiencies in the prior art, the present invention provides a manufacturing method of a novel aluminum alloy floor, which has good mechanical properties, strong compression resistance and deformation resistance, and can avoid oxidation of the aluminum alloy surface, and has better appearance and Thermal conductivity, easy maintenance and secondary use after installation.

[0029] In order to solve the problems of the technologies described above, the present invention adopts the following technical solutions:

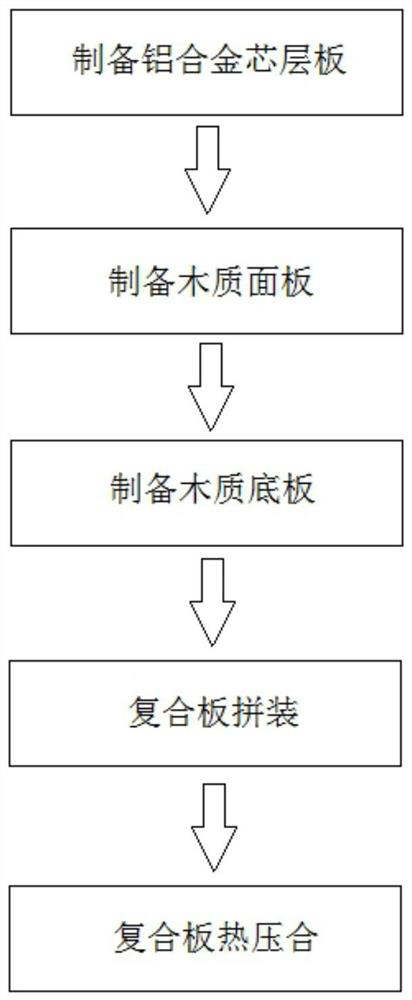

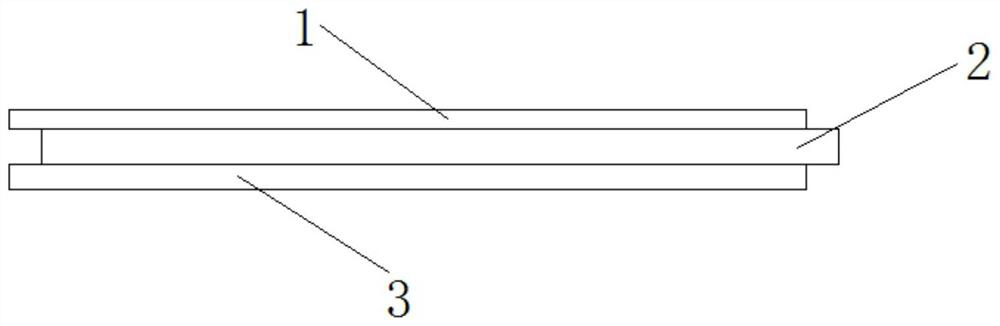

[0030] As an implementation, such as figure 1 As shown, a method for manufacturing a novel aluminum alloy floor, the aluminum alloy floor includes a wooden panel 1, an aluminum alloy core board 2 and a wooden bottom plate 3, and the manufacturing method for the aluminum alloy floor includes the following steps:

[0031] Step 1, preparing the aluminum alloy core plate: heating the aluminum alloy rod to melt it, pouring the melted metal liquid into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com