High-thermal-conductivity strong-insulation epoxy composite material for solid-state transformer under low doping amount and preparation method thereof

A technology of solid-state transformers and composite materials, applied in the field of thermally conductive and insulating composite materials, can solve the problems of iron core hysteresis loss, coil insulation material loss and heat generation, damage to insulation performance, large amount of filler doping, etc., and achieve low dielectric constant and loss , Improve the electrical insulation performance, and the effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

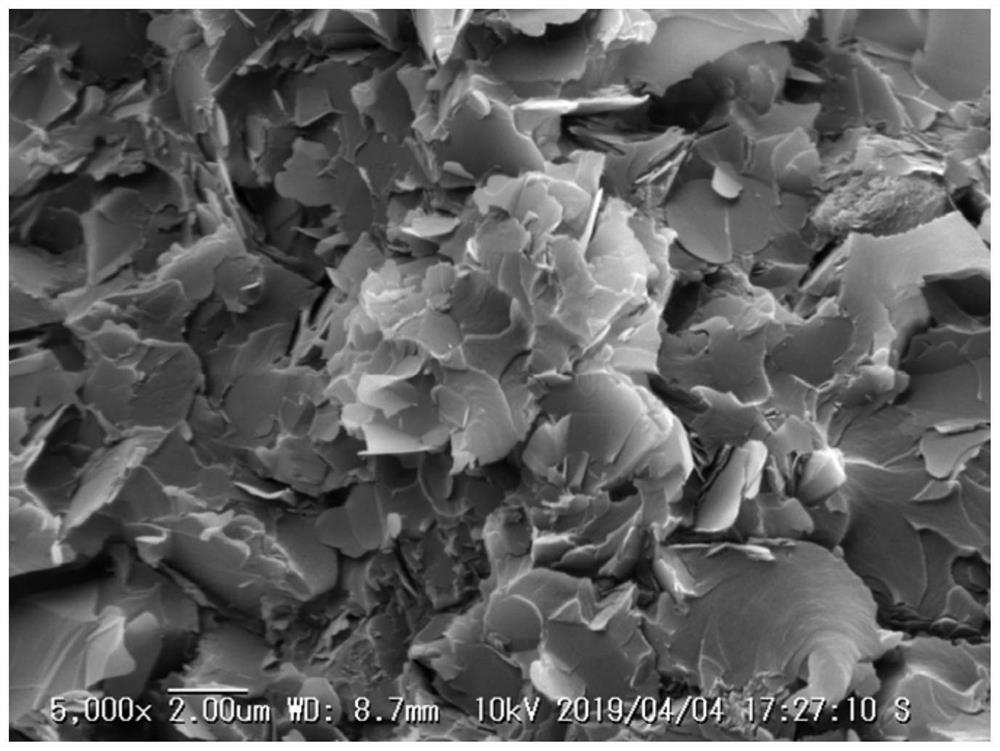

[0057] This embodiment provides an epoxy composite material with high thermal conductivity and strong insulation for solid-state transformers and a preparation method thereof. The proportion of nano-boron nitride particles in the filler system is 4.994wt%. (1) First prepare nano-silica-coated boron nitride microparticles and modified nano-boron nitride particles with a core-shell structure:

[0058] Weigh 1 g of micron boron nitride particles and disperse them into 100 ml of absolute ethanol (analytical pure), and add 25 ml of deionized water (analytical pure). Heat in a constant temperature water bath, control the temperature at 35°C, ultrasonically disperse and stir with a magnetic rotor for 45 minutes, and make a crude BN suspension. 12ml ammonia water (NH 3 content between 30% by weight) was added to the BN suspension, and then 0.2ml of TEOS (tetraethylorthosilicate, analytically pure) was added dropwise, and reacted at room temperature for 12 hours. After the reaction, ...

Embodiment 2

[0070] This embodiment provides an epoxy composite material with high thermal conductivity and strong insulation for solid-state transformers and its preparation method. The proportion of nano boron nitride particles in the filler system is 3 wt%.

[0071] (1) First prepare nano-silica-coated boron nitride microparticles and modified nano-boron nitride particles with a core-shell structure:

[0072] Weigh 1 g of micron boron nitride particles and disperse them into 100 ml of absolute ethanol (analytical pure), and add 25 ml of deionized water (analytical pure). Heat in a constant temperature water bath, control the temperature at 20°C, ultrasonically disperse and stir with a magnetic rotor for 60 minutes, and make a crude BN suspension. 12mL ammonia water (NH 3 content between 25% by weight) was added to the BN suspension, and then 0.2 mL of TEOS (tetraethylorthosilicate, analytically pure) was added dropwise, and reacted at room temperature for 14 hours. After the reaction,...

Embodiment 3

[0083] This embodiment provides an epoxy composite material with high thermal conductivity and strong insulation for solid-state transformers and a preparation method thereof. The proportion of nano-boron nitride particles in the filler system is 5 wt%.

[0084] (1) First prepare nano-silica-coated boron nitride microparticles and modified nano-boron nitride particles with a core-shell structure:

[0085] Weigh 1 g of micron boron nitride particles and disperse them into 100 ml of absolute ethanol (analytical pure), and add 25 ml of deionized water (analytical pure). Heat in a constant temperature water bath, control the temperature at 40°C, ultrasonically disperse and stir with a magnetic rotor for 30 minutes, and make a crude BN suspension. 12mL ammonia water (NH 3 content between 20% by weight) was added to the BN suspension, and then 0.2mLTEOS (tetraethyl orthosilicate, analytically pure) was added dropwise, and reacted at room temperature for 15 hours. After the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com