Rare earth ceramsite and preparation method thereof

A ceramsite and rare earth technology, applied in the field of rare earth ceramsite and its preparation, can solve the problems of low impact resistance, long drying time, and easy breakage of ceramsite, and achieve long regeneration cycle, simple and convenient regeneration, and small filtration resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

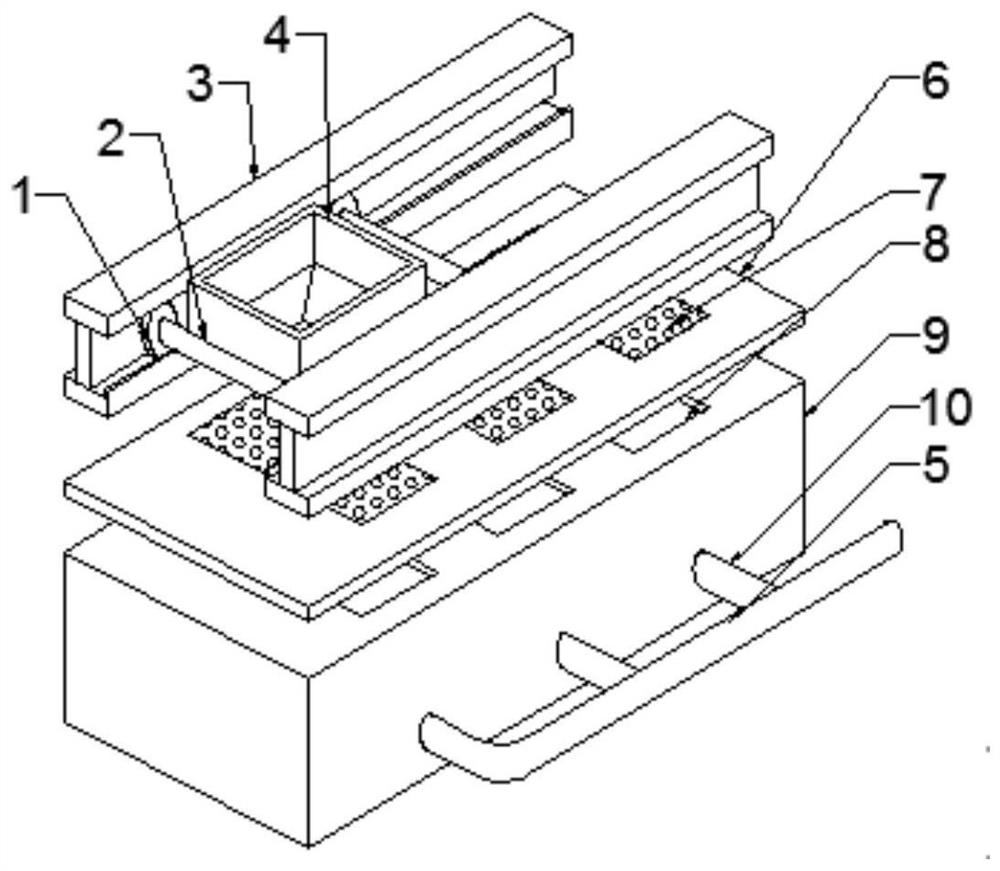

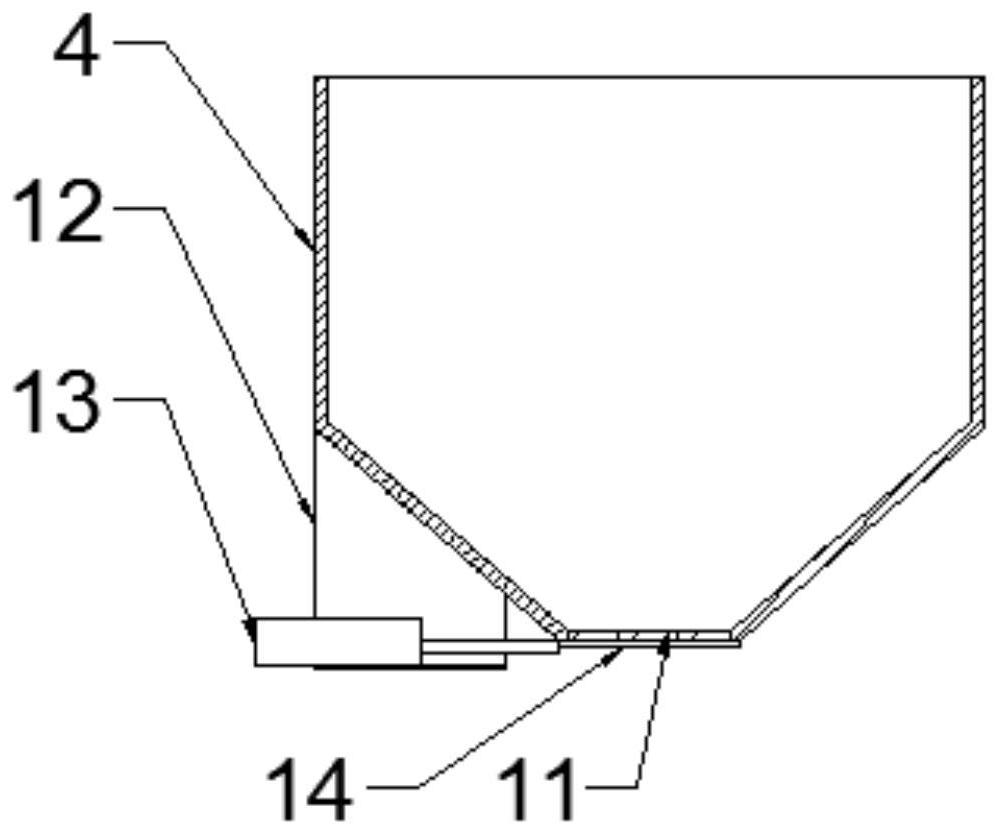

Image

Examples

Embodiment 1

[0037] Embodiment 1: a kind of rare earth ceramsite, main material comprises kaolin and potassium feldspar; Auxiliary material comprises pore-forming agent and bonding agent; pore-forming agent selects bamboo wood powder for use, binder selects latex powder for use;

[0038] The parts by weight of kaolin, potassium feldspar, bamboo wood powder and latex powder are 10 parts of kaolin, 8 parts of potassium feldspar, 2 parts of powder made from flue-cured tobacco rods, and 2.5 parts of latex powder.

Embodiment 2

[0039] Embodiment 2: the difference with Example 1 is that the parts by weight of kaolin, potassium feldspar, bamboo wood powder and latex powder are the powder that 8 parts of kaolin, 9 parts of potassium feldspar, bamboo wood powder+cured tobacco rod break into ( 1:1) 3 parts, latex powder 3 parts.

Embodiment 3

[0040] Embodiment 3: The difference with Example 1 is that the parts by weight of kaolin, potassium feldspar, bamboo wood powder and latex powder are 9 parts of kaolin, 7 parts of potassium feldspar, 2.5 parts of bamboo wood powder, and 2 parts of latex powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com