ETHYLENE/alpha-OLEFIN/NON-CONJUGATED POLYENE COPOLYMER, PRODUCTION METHOD THEREFOR, AND USE

A non-conjugated polyene and manufacturing method technology, applied in transportation and packaging, special tires, tire parts, etc., can solve problems such as insufficient processability, reduced crosslink density, stickiness, etc., and achieve excellent curing properties , Prevent phase separation, excellent balance of physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0762] use figure 1 The continuous polymerization apparatus shown was operated as follows to produce an ethylene-propylene-VNB copolymer.

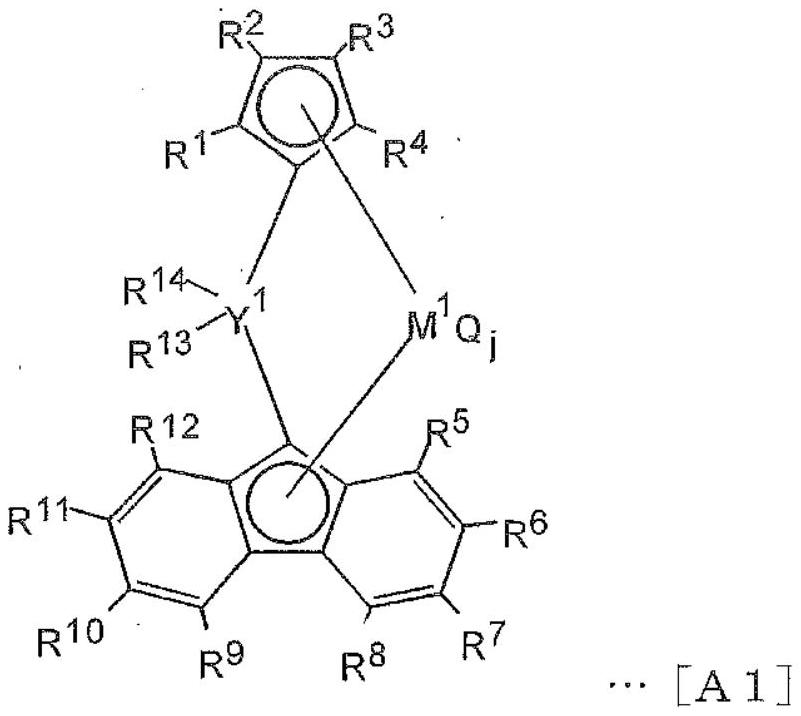

[0763] In the polymerization reactor C with a volume of 300 liters, the dehydrated and refined hexane solvent was continuously supplied from the pipe 6 at 58.3 L / hr, and the triisobutylaluminum (TiBA) was continuously supplied from the pipe 7 at 4.5 mmol / hr. 0.150mmol / hr continuous supply (C 6 h 5 ) 3 CB(C 6 f 5 ) 4 , Bis(p-tolyl)methylene(cyclopentadienyl)(octamethyloctahydrodibenzofluorenyl)zirconium dichloride was continuously supplied at 0.030 mmol / hr. At the same time, into the polymerization reactor C, ethylene was continuously supplied at 6.6 kg / hr, propylene was continuously supplied at 9.3 kg / hr, hydrogen was continuously supplied at 18 liters / hr, and 340 g / hr of VNB was continuously supplied, and copolymerization was carried out under the conditions of a polymerization temperature of 87° C., a total pressure of 1.6 MPaG, a...

Embodiment 2~4

[0777] Except having changed the production conditions of the ethylene-propylene-VNB copolymer to the conditions shown in Table 1, it carried out similarly to Example 1, and produced the ethylene-propylene-VNB copolymer. The production results are shown in Table 1. In addition, the physical properties of the obtained ethylene-propylene-VNB copolymer were evaluated in the same manner as in Example 1. The results are shown in Table 2. In addition, the molecular weight distribution of the obtained ethylene-propylene-VNB copolymer showed bimodality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com