Method for preparing ZnTe doped p-type polycrystalline Bi2Te3 thermoelectric material

A thermoelectric material, p-type technology, used in the growth of polycrystalline materials, the junction lead-out material of thermoelectric devices, the manufacture/processing of thermoelectric devices, etc. , difficult to wait

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

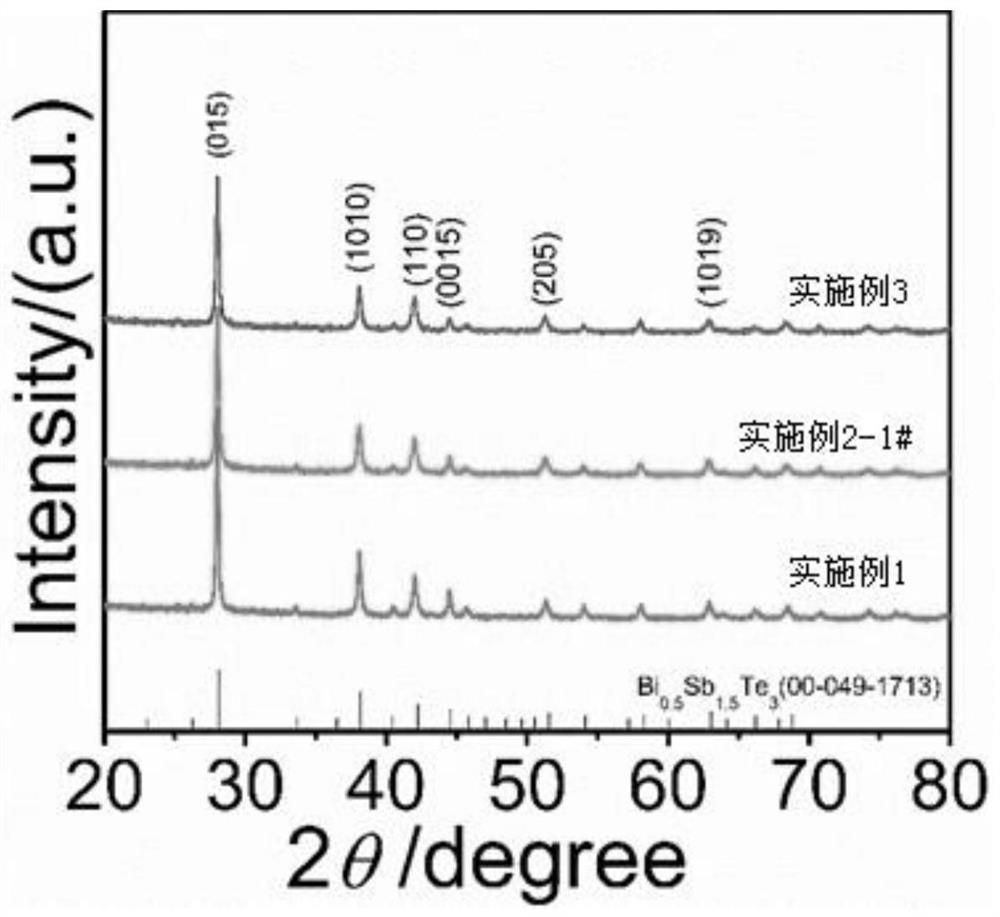

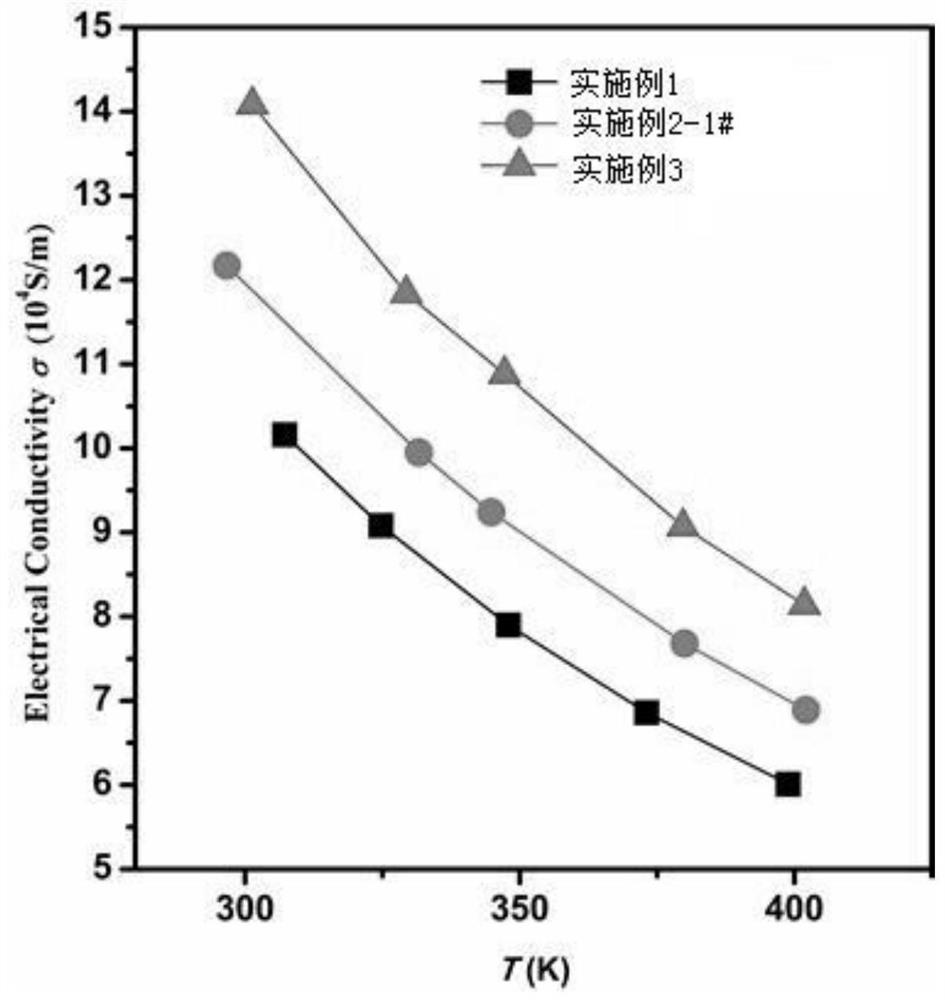

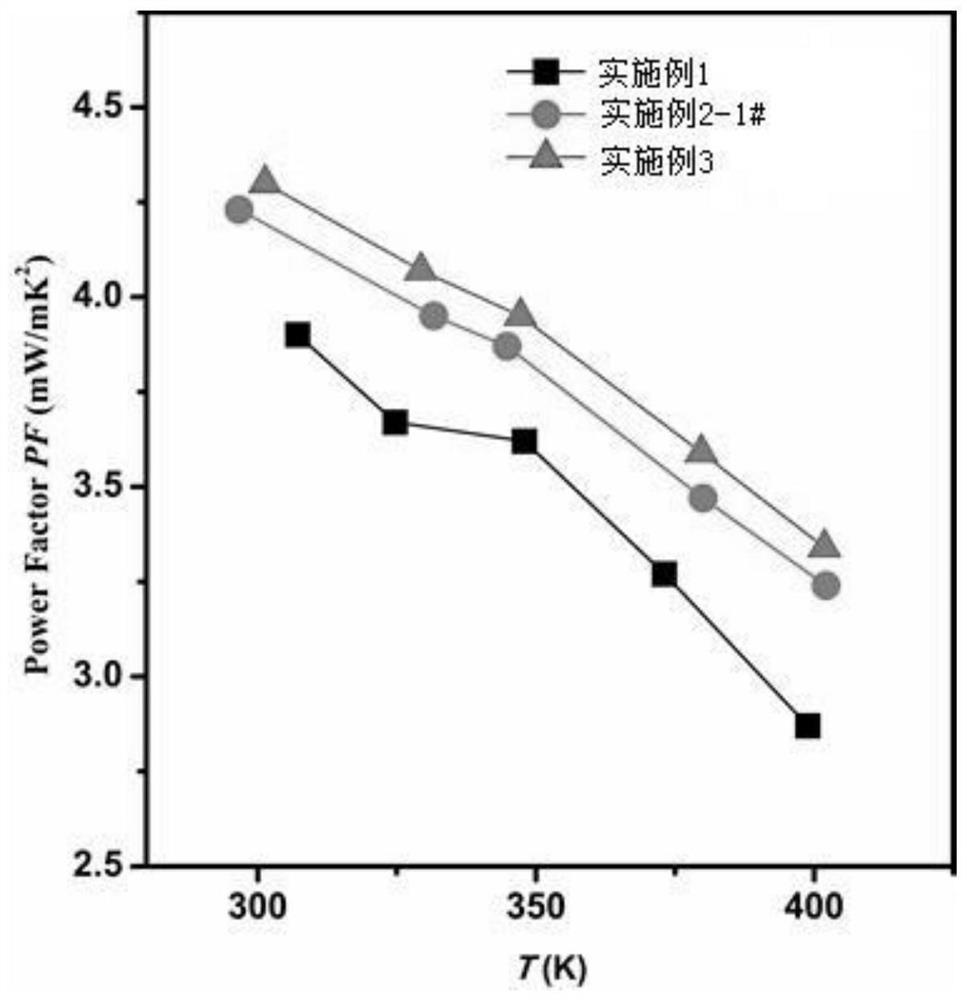

Embodiment 1

[0030] A preparation of ZnTe-doped p-type polycrystalline Bi 2 Te 3 The method of thermoelectric material, concrete steps are as follows:

[0031] (1) Using high-purity Bi, Sb, Te, Zn as initial raw materials, according to Zn 0.015 Bi 0.46 Sb 1.54 Te 3.015 The stoichiometric ratio of each element is weighed and vacuum-sealed in a quartz tube, the quartz tube is placed in a melting furnace, melted at 1123K for 10 hours, and cooled with the furnace to obtain an ingot;

[0032] (2) The ingot body that step (1) is obtained is carried out melt spinning, and protective atmosphere is argon gas, and copper stick rotating speed is 8m / s, and injection aperture is 0.35mm;

[0033] (3) Collect the thin strip obtained in step (2), then vacuum-seal it in a quartz tube, put it into the sample for annealing after the temperature of the annealing furnace reaches 423K, and the annealing time is 20min;

[0034](4) Grinding the annealed thin strip through a 200-mesh sieve and then performin...

Embodiment 2

[0041] A preparation of ZnTe-doped p-type polycrystalline Bi 2 Te 3 The method of thermoelectric material, concrete steps are as follows:

[0042] (1) Using high-purity Bi, Sb, Te, Zn as initial raw materials, according to Zn 0.015 Bi 0.46 Sb 1.54 Te 3.015 The stoichiometric ratio of each element is weighed and vacuum-sealed in a quartz tube, the quartz tube is placed in a melting furnace, melted at 1123K for 10 hours, and cooled with the furnace to obtain an ingot;

[0043] (2) The ingot body that step (1) is obtained is carried out melt spinning, and protective atmosphere is argon, and copper stick rotating speed is 4m / s, and injection aperture is 0.35mm;

[0044] (3) Collect the thin strips obtained in step (2), and then vacuum-seal them in a quartz tube. When the temperature of the annealing furnace reaches 423K, put the sample into the sample for annealing, and the annealing time is 20 minutes;

[0045] (4) Grinding the annealed thin strip through a 200-mesh sieve ...

Embodiment 3

[0052] A preparation of ZnTe-doped p-type polycrystalline Bi 2 Te 3 The method of thermoelectric material, concrete steps are as follows:

[0053] (1) Using high-purity Bi, Sb, Te, Zn as initial raw materials according to Zn 0.015 Bi 0.46 Sb 1.54 Te 3.015 The stoichiometric ratio of each element is weighed and vacuum-sealed in a quartz tube, the quartz tube is placed in a melting furnace, melted at 1123K for 10 hours, and cooled with the furnace to obtain an ingot;

[0054] (2) The ingot body obtained in step (1) is subjected to melt spinning, the protective atmosphere is argon, the rotational speed of the copper rod is 4 m / s, and the injection diameter is 0.35 mm.

[0055] (3) Collect the thin strips obtained in step (2), and then vacuum-seal them in a quartz tube. When the temperature of the annealing furnace reaches 523K, put the sample into it for annealing, and the annealing time is 20min.

[0056] (4) Grinding the annealed thin strip through a 200-mesh sieve and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com