Thin warm type aerogel textile fiber fabric and preparation method thereof

A textile fiber and airgel technology, applied in the field of textile fabrics, can solve the problems of poor warmth retention and wearability, and achieve the effects of broadening the application range, improving quick-drying performance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

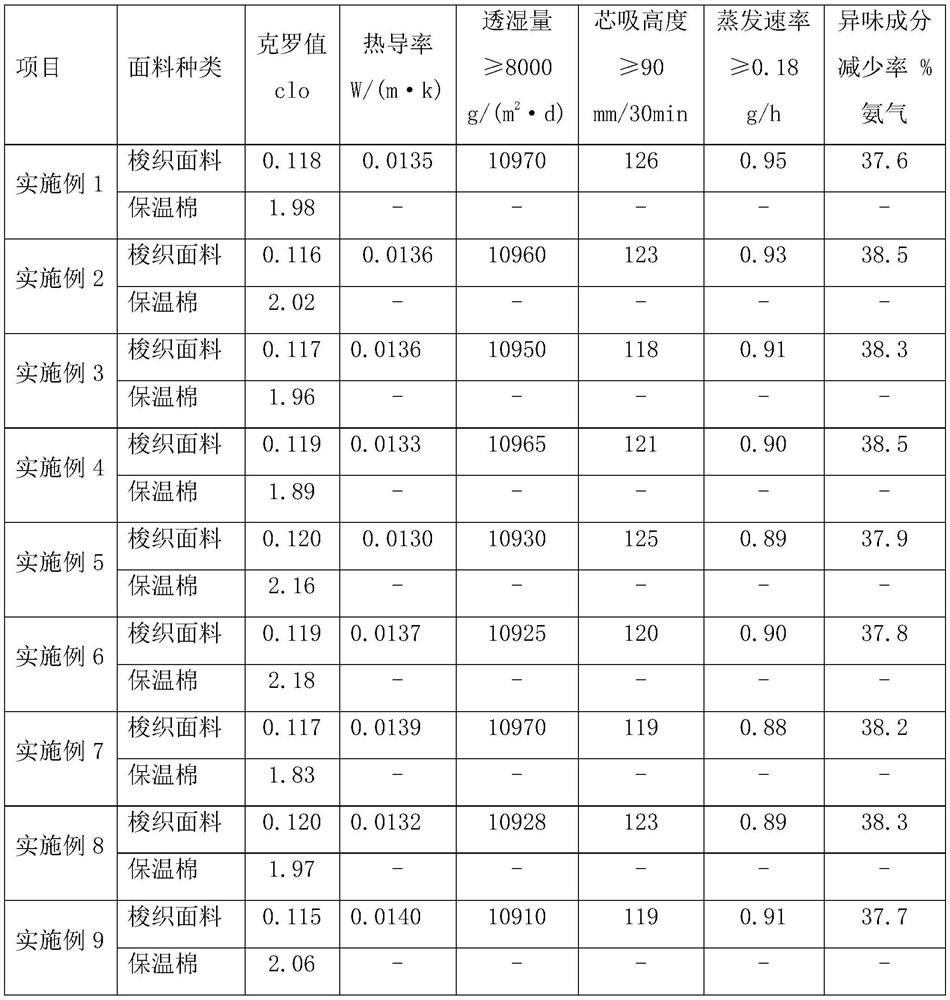

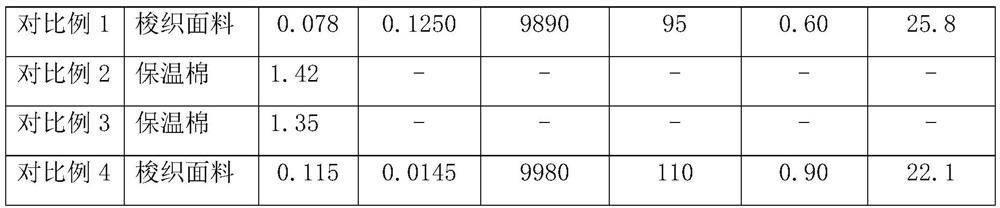

Examples

Embodiment 1

[0038] A thin warm airgel textile fiber fabric, comprising the following components in weight percentage: 10% of silica airgel modified fiber, the rest of cashmere fiber or wool fiber or cotton fiber, wherein silica gas The specific surface area of the gel is 600m 2 / g~1000m 2 / g, porosity of 95% to 99%; airgel modified fiber includes airgel and matrix fiber with a mass ratio of 1:10, wherein the matrix fiber is polyester fiber; a thin warm airgel The preparation method of textile fiber fabric, comprises the following steps:

[0039] S1. Pelletizing of modified polyester: Pelletizing airgel modified polyester according to specific specifications;

[0040] S2, melt spinning: the airgel modified polyester pellets prepared in step S1 are melt-spun through a melt spinning machine to obtain airgel modified polyester textile fibers, airgel modified polyester Textile fibers include airgel modified polyester fiber filaments and airgel modified polyester staple fibers, wherein airge...

Embodiment 2

[0043] A thin warm airgel textile fiber fabric, comprising the following components in weight percentage: 20% of silica airgel modified fiber, the rest of cashmere fiber or wool fiber or cotton fiber, wherein silica gas The specific surface area of the gel is 600m 2 / g~1000m 2 / g, porosity of 95% to 99%; airgel modified fiber includes airgel and matrix fiber with a mass ratio of 1:45, wherein the matrix fiber is polyester fiber; a thin warm airgel The preparation method of textile fiber fabric, comprises the following steps:

[0044] S1. Pelletizing of modified polyester: Pelletizing airgel modified polyester according to specific specifications;

[0045] S2, melt spinning: the airgel modified polyester pellets prepared in step S1 are melt-spun through a melt spinning machine to obtain airgel modified polyester textile fibers, airgel modified polyester Textile fibers include airgel modified polyester fiber filaments and airgel modified polyester staple fibers, wherein air...

Embodiment 3

[0048] A thin warm airgel textile fiber fabric, comprising the following components in weight percentage: 30% of silica airgel modified fiber, the rest of cashmere fiber or wool fiber or cotton fiber, wherein silica gas The specific surface area of the gel is 600m 2 / g~1000m 2 / g, porosity of 95% to 99%; airgel modified fiber includes airgel and matrix fiber with a mass ratio of 1:80, wherein the matrix fiber is polyester fiber; a thin warm airgel The preparation method of textile fiber fabric, comprises the following steps:

[0049] S1. Pelletizing of modified polyester: Pelletizing airgel modified polyester according to specific specifications;

[0050] S2, melt spinning: the airgel modified polyester pellets prepared in step S1 are melt-spun through a melt spinning machine to obtain airgel modified polyester textile fibers, airgel modified polyester Textile fibers include airgel modified polyester fiber filaments and airgel modified polyester staple fibers, wherein air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com