Method for degumming hemp

A hemp degumming and degumming technology, applied in the field of hemp degumming, can solve the problems of large degumming water consumption, expensive equipment, low quality and low efficiency, etc., and achieve the effect of high raw material utilization rate, high degumming efficiency and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

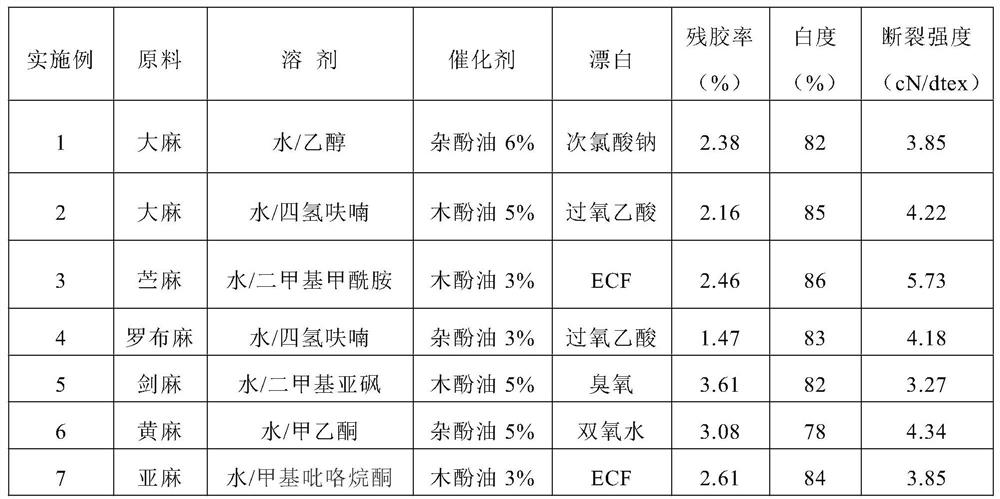

Examples

Embodiment 1

[0034] 1. Catalytic cooking

[0035] Choose the loose hemp after the dedusting of dry weight 10 kilograms, put into pressure cooker, add 14L water, 80L ethanol (95%), 6L creosote (produced by Shanxi Jinyuan Coal Chemical Technology Co., Ltd., density 0.98-1.01, distilled 160-180°C), heated to 150°C, kept warm for 1 hour, and then extruded to release the cooking liquid.

[0036] 2. Solvent washing

[0037] Add the hemp fiber obtained in step 1 to 70L of 95% ethanol for replacement washing, circulate for 20 minutes, extrude the solvent, then re-add new ethanol washing solvent, repeat three times, keep the washing temperature at 60°C, and then extrude detergent. Add the hemp fiber to 100L water and heat it to 95°C to evaporate the residual ethanol. The evaporated ethanol contains azeotropic water and enters the alcohol-water separation equipment for recycling and reuse of ethanol.

[0038] 3. Washing

[0039] Wash the hemp fiber obtained in step 2 with 80L of water, wash with...

Embodiment 2

[0047] 1. Catalytic cooking

[0048] Choose the dedusted open cannabis with a dry weight of 10 kg, put it into a pressure cooker, add 20L of water, 75L of industrial tetrahydrofuran, and 5L of wood phenol oil (produced by Zhiyuan Biochemical Co., Ltd., Yongan City, Fujian Province, natural phenol content (GC)> 55%, specific gravity 1.12, distillation range 180-200°C), heated to 120°C, kept for 1.5 hours, and then extruded to release the cooking liquid.

[0049] 2. Solvent washing

[0050] Add the hemp fiber obtained in step 1 to 60L tetrahydrofuran for replacement washing, circulate for 20 minutes, squeeze out the solvent, then re-add new tetrahydrofuran, repeat three times, keep the washing temperature at 40°C, and then squeeze out the washing liquid. Add the hemp fiber to 80L of water and heat it to 90°C to evaporate the residual tetrahydrofuran.

[0051] 3. Washing

[0052] The hemp fiber that step 2 obtains is washed with 80L water, carries out water washing three times...

Embodiment 3

[0060] 1. Catalytic cooking

[0061] Choose the scraped green ramie skin after dust removal with a dry weight of 10 kg, put it into a pressure cooker, add 17L water, 80L dimethylformamide, 3L wood phenol oil (produced by Zhiyuan Biochemical Co., Ltd., Yongan City, Fujian Province, natural phenol content (GC) > 55%, specific gravity 1.12, distillation range 180-200°C), heated to 150°C, kept for 0.5 hours, and then extruded to release the cooking liquid.

[0062] 2. Solvent washing

[0063] Add 80L dimethylformamide to the hemp fiber obtained in step 1 for replacement washing, circulate for 20 minutes, extrude to release the solvent, then re-add new dimethylformamide, repeat three times, keep the washing temperature at 80°C, and then extrude Squeeze out the washing liquid.

[0064] 3. Washing

[0065] The hemp fiber that step 2 obtains is washed with 80L water, carries out water washing three times, emits waste water after extruding.

[0066] 4. Bleaching

[0067] Using the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com