Controllable surface nitriding device and using method thereof

A nitriding and vacuum device technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of uneven nitriding on the workpiece surface, uneven performance distribution, and adsorption on a certain workpiece surface. and other problems, to achieve the effect of improving mechanical properties and novel device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

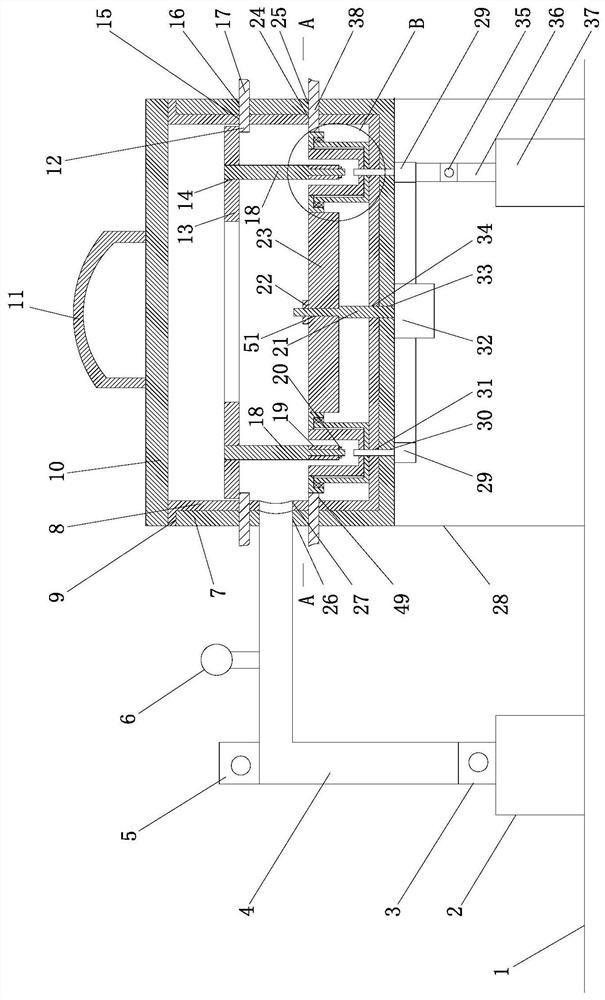

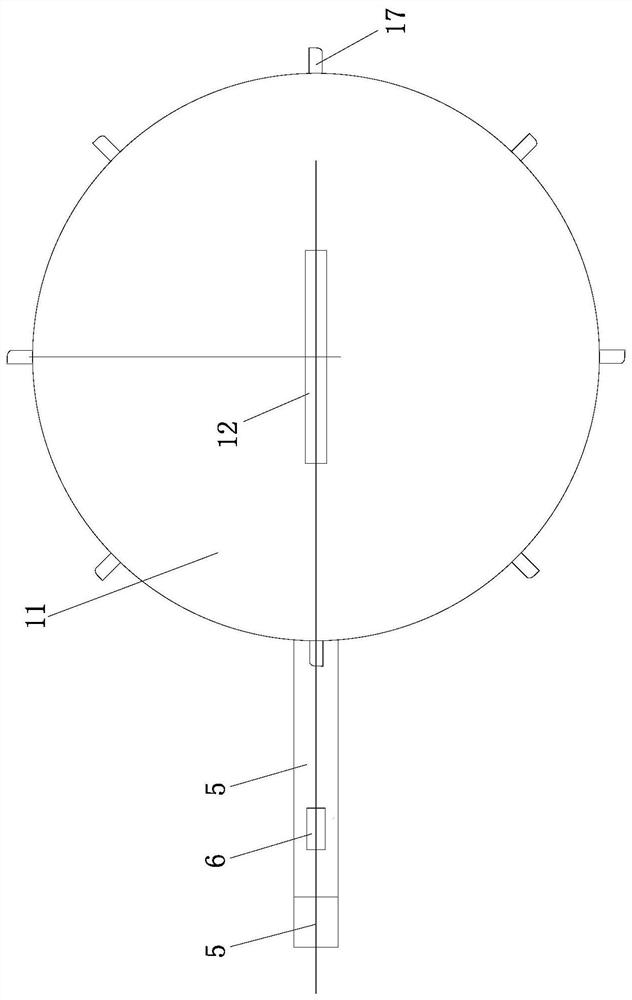

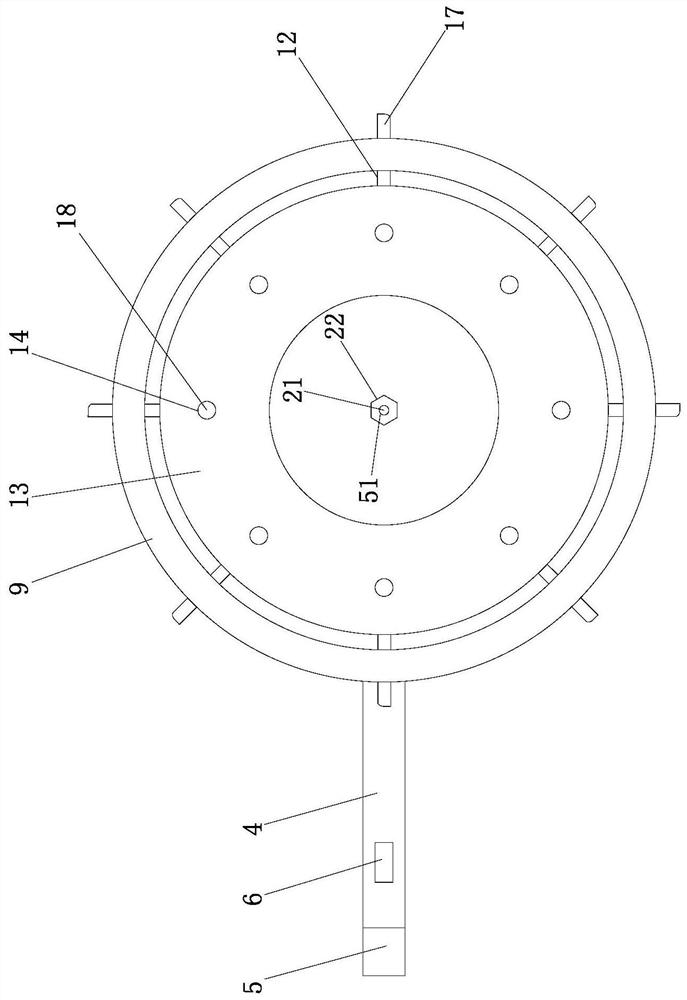

[0024] Such as Figure 1-7 As shown, a controllable surface nitriding device is composed of a vacuum device, a surface nitriding control mechanism and a nitrogen gas supply structure.

[0025] Such as Figure 1-7As shown, a controllable surface nitriding device, the vacuum device consists of a vacuum pump 2, a first solenoid valve 3, a metal pipe 4, a second solenoid valve 5, a pressure gauge 6, a vacuum chamber shell 7, an insulating inner pad 8, a gland 10. The support frame 28 is composed of; the metal pipe 4 is connected to the vacuum pump 2 through the first solenoid valve 3, the second solenoid valve 5 and the pressure gauge 6 are all set on the metal pipe 4, and the vacuum chamber shell 7 is supported on the ground 1 through the support frame 28. Above, the insulating inner pad 8 is arranged on the inner wall of the vacuum chamber shell 7, the top of the insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com