Modified nanoscale zero-valent iron and preparation method and application thereof

A nano-zero-valent iron, modified technology, applied in transportation and packaging, metal processing equipment, etc., can solve the problem of the decrease in the mobility and activity of nano-zero-valent iron particles, reduce the adsorption sites of nano-zero-valent iron particles, and adversely affect nano-zero-valent iron particles. Solving problems such as the fluidity of valence iron particles, to achieve good application value, good stability efficiency, and improve the effect of dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

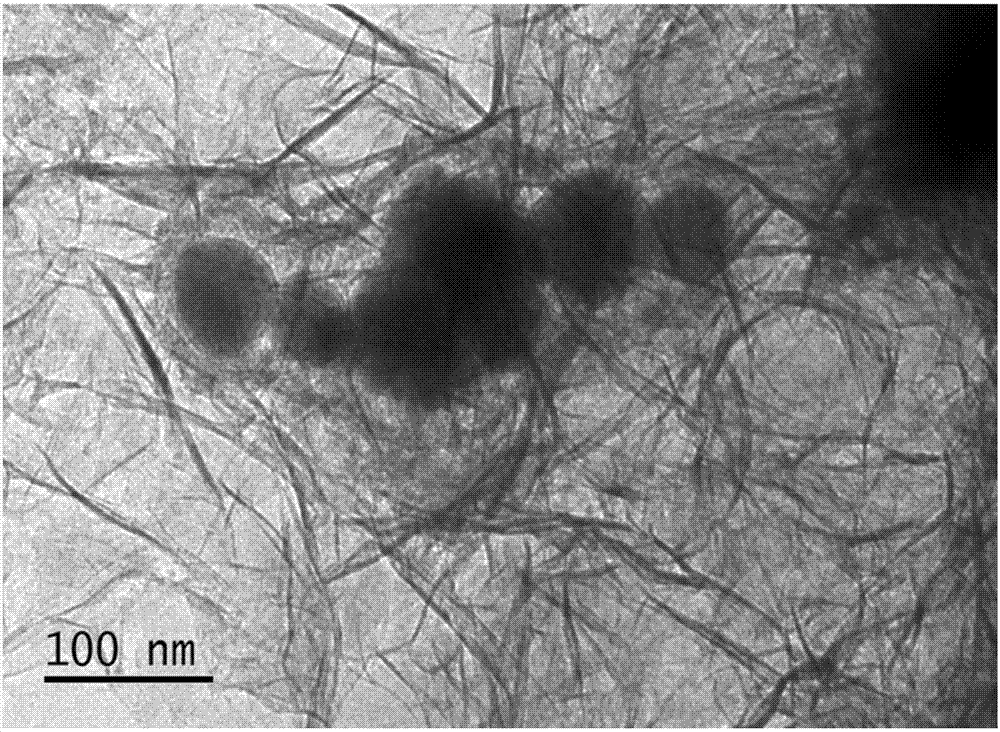

Image

Examples

Embodiment 1

[0039] A modified nano-zero-valent iron, the modified nano-zero-valent iron includes rhamnolipid (RL) and nano-zero-valent iron, and the rhamnolipid is modified on the surface of the nano-zero-valent iron, wherein the rhamnolipid is a dispersant .

[0040] In this embodiment, the mass ratio of rhamnolipid to nanometer zero-valent iron is 0.1:1.

[0041] In this embodiment, the particle size of the modified nano zero-valent iron is 120nm.

[0042] A preparation method of the modified nano zero-valent iron in the above-mentioned present embodiment, comprising the following steps:

[0043] (1) Prepare the solution:

[0044] FeSO 4 Solution preparation: weigh 0.496g FeSO 4 ·7H 2 Put O in a beaker, add an appropriate amount of ultrapure water to dissolve it and transfer it to a 25mL volumetric flask, use ultrapure water to make up the volume to the mark, shake well, and obtain FeSO with a concentration of 0.07M 4 solution.

[0045] Preparation of rhamnolipid solution: Weigh ...

Embodiment 2

[0049] A modified nano-zero-valent iron, which is basically the same as the modified nano-zero-valent iron in Example 1, the only difference being that the mass ratio of rhamnolipid to nano-zero-valent iron in Example 2 is 0.3:1.

[0050] A method for preparing the modified nano-zero-valent iron of the above-mentioned embodiment is basically the same as that of the embodiment 1, except that the concentration of the rhamnolipid solution in the embodiment 2 is 0.6 g / L. The modified nano zero-valent iron (RL-nZVI) suspension prepared by the method is coded as R2.

Embodiment 3

[0052] A modified nano-zero-valent iron, which is basically the same as the modified nano-zero-valent iron in Example 1, the only difference being that the mass ratio of rhamnolipid to nano-zero-valent iron in Example 3 is 0.5:1.

[0053] A method for preparing the modified nano-zero-valent iron of the above-mentioned embodiment is basically the same as that of the embodiment 1, except that the concentration of the rhamnolipid solution in the embodiment 3 is 1 g / L. The modified nano zero-valent iron (RL-nZVI) suspension prepared by the method is numbered R3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com