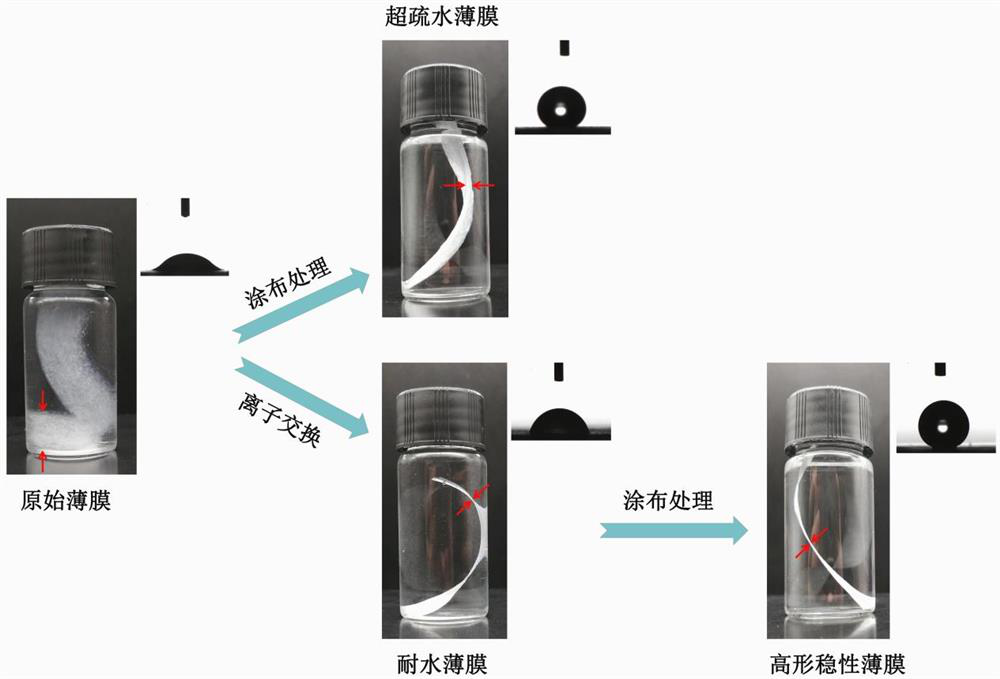

A kind of cellulose-based transparent waterproof film with high shape stability and preparation method thereof

A cellulose-based, waterproof film technology, applied in coatings and other directions, can solve the problems of inability to prevent small-volume water molecules from attacking layer by layer, dimensional stability effects, etc., to reduce electrostatic repulsion, reduce energy consumption, and improve water filtration. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of cellulose base transparent waterproof film of high shape stability, its preparation method comprises the steps:

[0045] (1) Using bleached hardwood pulp fiber as raw material, TEMPO oxidation pretreatment method was used to weigh 2,2,6,6-tetramethylpiperidine-nitrogen-oxide (TEMPO ) and 10wt% of dry pulp were weighed NaBr in a beaker, added distilled water to 100mL, and dissolved under magnetic stirring, stand-by. Transfer 200 g of bleached hardwood pulp fibers with a mass concentration of 10% to a round bottom flask, add 1000 g of water, and stir the slurry at a speed of 500 r / min. After stirring for 30 minutes, add sodium bromide solution and TEMPO solution in turn. Then weigh the NaClO solution according to 1 g of absolute dry pulp corresponding to 8 mmol NaClO, slowly add it into the flask, add distilled water to adjust the slurry concentration to 1.0%, and control the pH of the whole reaction process to maintain at 10.5. When the pH no longer drops, th...

Embodiment 2

[0050] A kind of cellulose base transparent waterproof film of high shape stability, its preparation method comprises the steps:

[0051] (1) Using bleached softwood pulp fiber as raw material, TEMPO oxidation pretreatment method was used to weigh 2,2,6,6-tetramethylpiperidine-nitrogen-oxide (TEMPO ) and 10wt% of dry pulp were weighed NaBr in a beaker, added distilled water to 100mL, and dissolved under magnetic stirring, stand-by. Transfer 200 g of bleached softwood pulp fibers with a mass concentration of 10% to a round bottom flask, add 1000 g of water, and stir the slurry at a speed of 500 r / min. After stirring for 30 minutes, add sodium bromide solution and TEMPO solution in turn. Then weigh the NaClO solution according to 1 g of absolute dry pulp corresponding to 8 mmol NaClO, slowly add it into the flask, add distilled water to adjust the slurry concentration to 1.0%, and control the pH of the whole reaction process to maintain at 10.5. When the pH no longer drops, th...

Embodiment 3

[0056] A kind of cellulose base transparent waterproof film of high shape stability, its preparation method comprises the steps:

[0057] (1) Using bamboo pulp fiber as raw material, TEMPO oxidation pretreatment method was used to weigh 2,2,6,6-tetramethylpiperidine-nitrogen-oxide (TEMPO) and Weigh 10wt% of dry pulp NaBr into a beaker, add distilled water to 100mL, dissolve under magnetic stirring, and set aside. Transfer 200 g of bamboo pulp fibers with a mass concentration of 10% to a round bottom flask, add 1000 g of water, and stir the slurry at a speed of 500 r / min. After stirring for 30 minutes, add sodium bromide solution and TEMPO solution in turn. Then weigh the NaClO solution according to 1 g of absolute dry pulp corresponding to 8 mmol NaClO, slowly add it into the flask, add distilled water to adjust the slurry concentration to 1.0%, and control the pH of the whole reaction process to maintain at 10.5. When the pH no longer drops, the reaction is complete. Then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com