Method for efficiently producing organic fertilizer

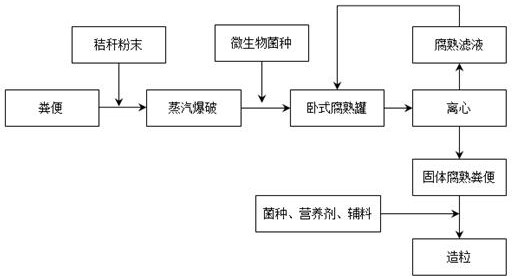

An organic fertilizer and high-efficiency technology, which is applied in the direction of organic fertilizer, bio-organic part treatment, and fertilizer made from biological waste, can solve the problems of accelerating the decomposition of organic fertilizer, long production cycle, and low production efficiency, so as to speed up the decomposition and improve the production efficiency. Improve production efficiency and improve the effect of deodorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

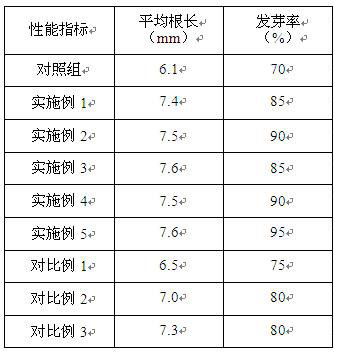

Embodiment 1

[0041] (1) Add the corn stalk powder passed through a 100-mesh sieve into pig manure to adjust the water content to 12.5%, then add ethanol, the amount of sodium cetylsulfonate is 7.5‰ of the mixed material, and the amount of ethanol 7.5% of the mixed material, stir evenly, then add the mixed material into the steam explosion tank and feed steam at a speed of 70mL / min, adjust the pressure in the steam explosion tank to 4.6MPa, keep the pressure for 12min, and then open the steam explosion tank instantly The bottom valve is used for steam explosion, and the material is discharged to obtain feces after steam explosion;

[0042] (2) Add 150kg of feces after steam explosion into the horizontal decomposing tank, then add 0.2kg of Bacillus subtilis, then adjust the water content of the feces by spraying the decomposing filtrate, and at the same time, feed oxygen to maintain the oxygen content, and then turn on the stirring rod to turn over For feces, the stirring rod of the horizont...

Embodiment 2

[0046] (1) Add rice straw powder passed through a 100-mesh sieve into cow dung to adjust the water content to 11%, and then add ethanol. The amount of polyoxyethylene fatty alcohol ether added is 6‰ of the mixed material, and the amount of ethanol added is 6% of the mixed material, stir evenly, then add the mixed material into the steam explosion tank and introduce steam at a speed of 65mL / min, adjust the pressure inside the steam explosion tank to 4.5MPa, keep the pressure for 14min, and then open the bottom of the steam explosion tank instantly The valve is used for steam explosion, and the material is discharged to obtain feces after steam explosion;

[0047] (2) Add 120kg of steam-exploded feces into the horizontal decomposing tank, then add 0.25kg of Bacillus megaterium, then adjust the water content of the feces by spraying the decomposing filtrate, while feeding oxygen to maintain the oxygen content, and then turn on the stirring rod to turn over For feces, the stirring...

Embodiment 3

[0051] (1) Add the sorghum stalk powder passed through a 100-mesh sieve into the chicken manure to adjust the water content to 14%, then add sodium cetyl sulfonate and ethanol, the amount of sodium cetyl sulfonate is 9‰, the amount of ethanol added is 9% of the mixed material, stir evenly, then add the mixed material into the steam explosion tank and feed steam at a speed of 75mL / min, adjust the pressure in the steam explosion tank to 4.8MPa, and keep the pressure for 11min , and then instantly open the bottom valve of the steam explosion tank, carry out steam explosion, discharge the material, and obtain feces after steam explosion;

[0052] (2) Add 180kg of feces after steam explosion into the horizontal decomposing tank, then add 0.15kg of Bacillus subtilis, then adjust the water content of the feces by spraying the decomposing filtrate, and at the same time feed oxygen to maintain the oxygen content, and then turn on the stirring rod to turn over For feces, the stirring ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com