Ultra-low loss optical fiber preparation method and corresponding optical fiber

An optical fiber preform and optical fiber technology, applied in the optical fiber field, can solve the problems of poor doping uniformity, crystallization, and difficulty in removing hydroxyl groups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

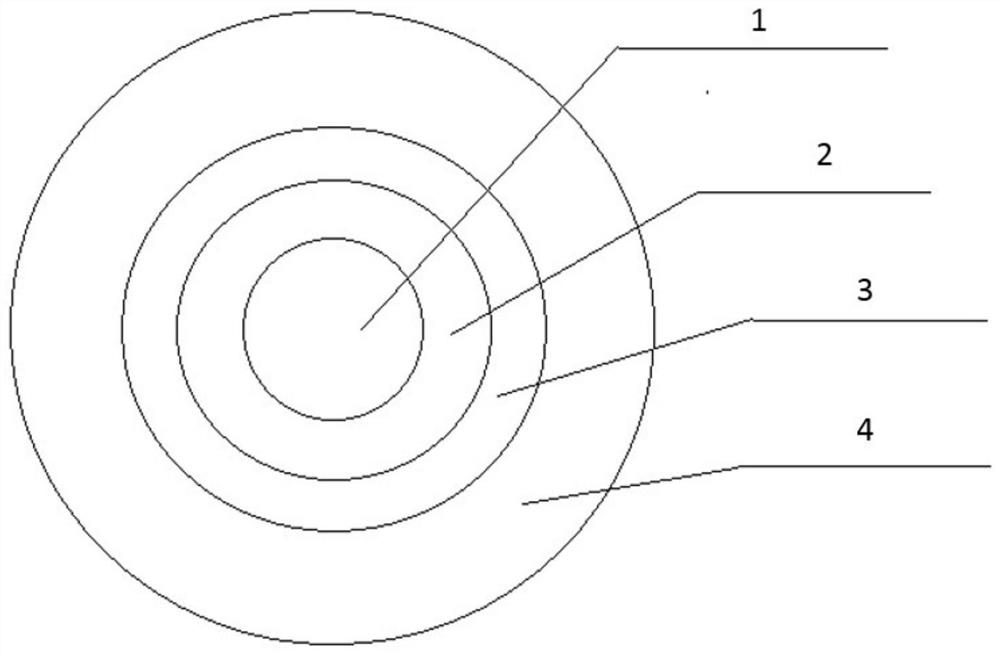

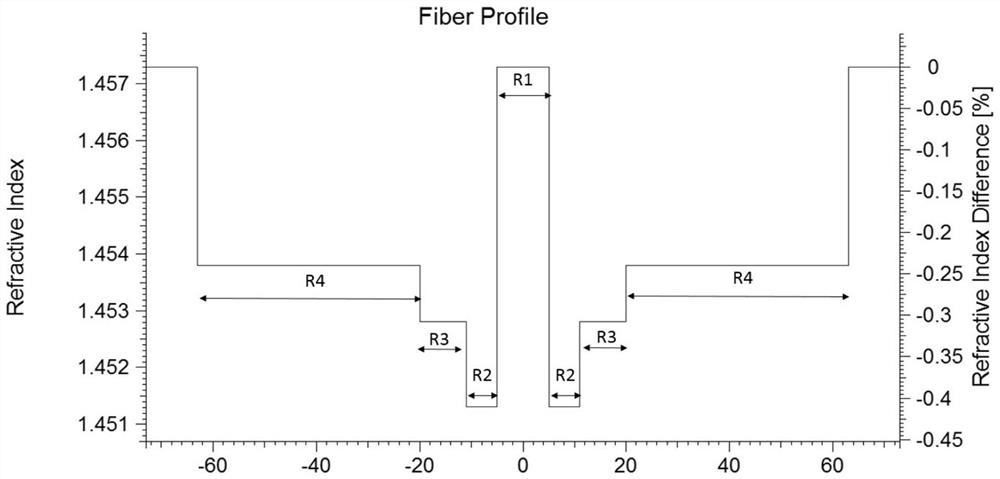

[0020] A method for preparing an ultra-low loss optical fiber, which comprises prefabricating an optical fiber preform, and then drawing the optical fiber preform to form an optical fiber. The manufacturing steps of the optical fiber preform are as follows: the core rod is prepared in advance by the VAD method, and the ultra-low loss alkali-doped optical fiber is prepared. In the process, alkali metal neutral salt should be used as raw material, and the oxygen-rich carrier gas is brought into the sintering furnace core tube for alkali metal doping. The temperature of the doping process is controlled within the range of 1000-1800 °C, and the doping time is controlled within 2-6 hours. , the alkali metal-doped core layer is prepared, and the alkali metal doping concentration is 20ppm-200ppm by hydrofluoric acid washing for 5-24h; after that, the self-made cladding heavily doped with fluorine is prepared by segmental fluorine infiltration and segmental sintering, ensuring The fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective area | aaaaa | aaaaa |

| Attenuation value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com