A kind of preparation method of zinc metastannate quantum dot

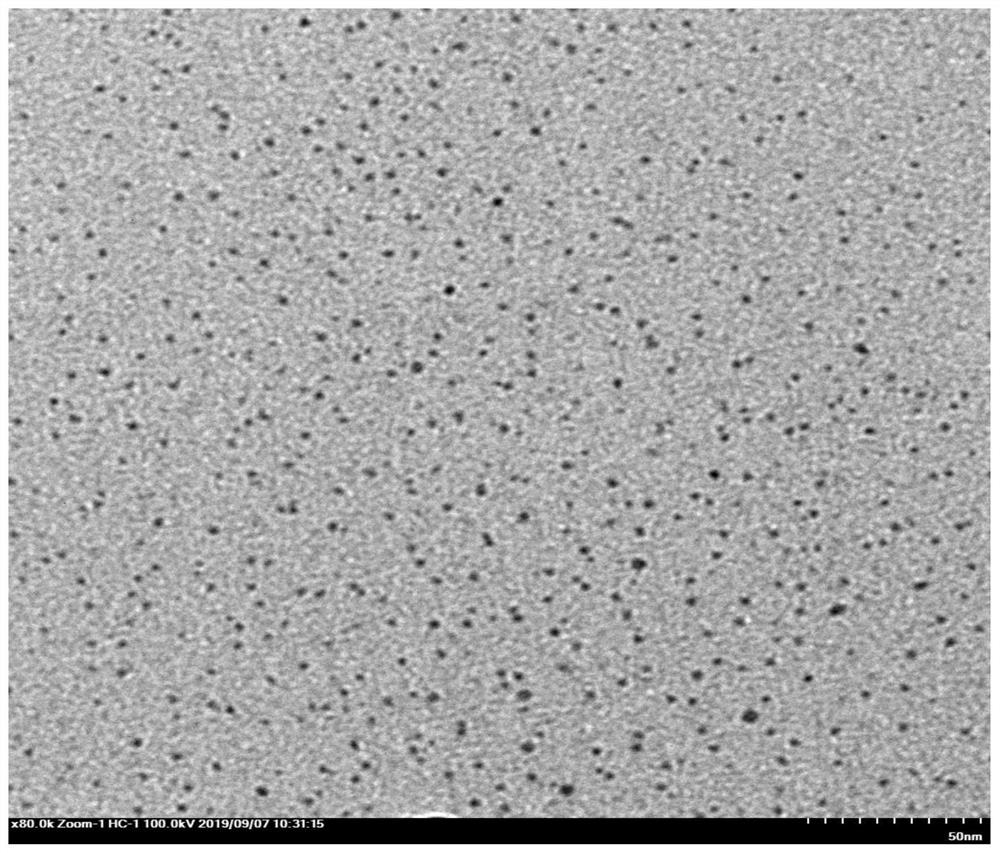

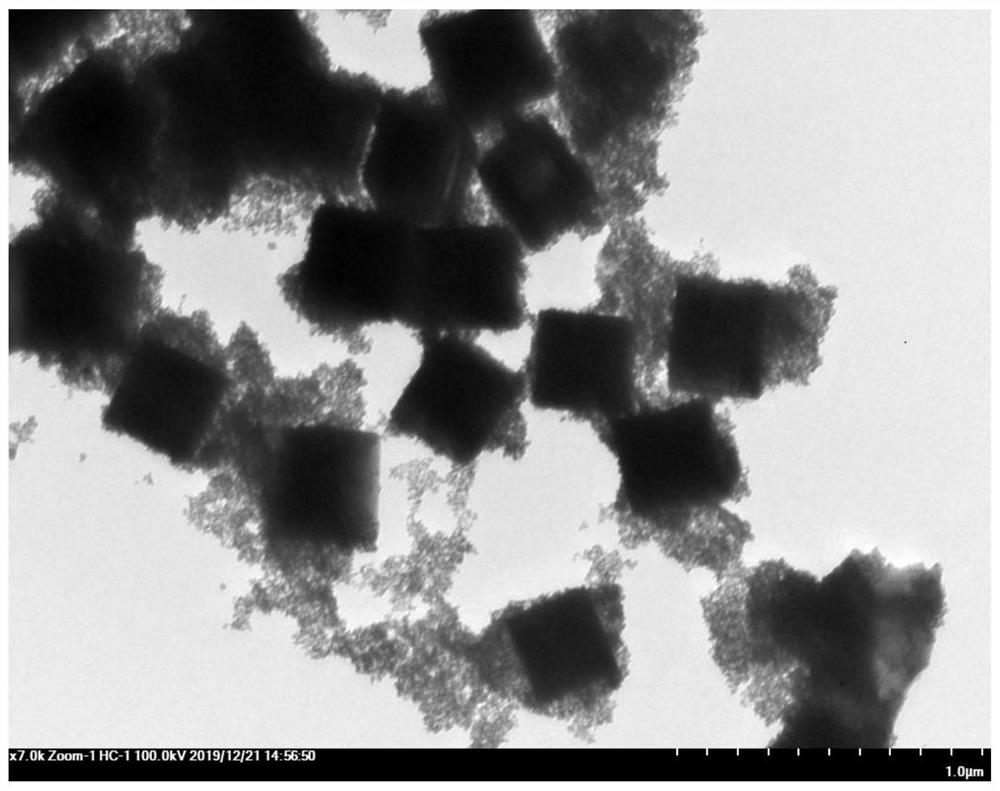

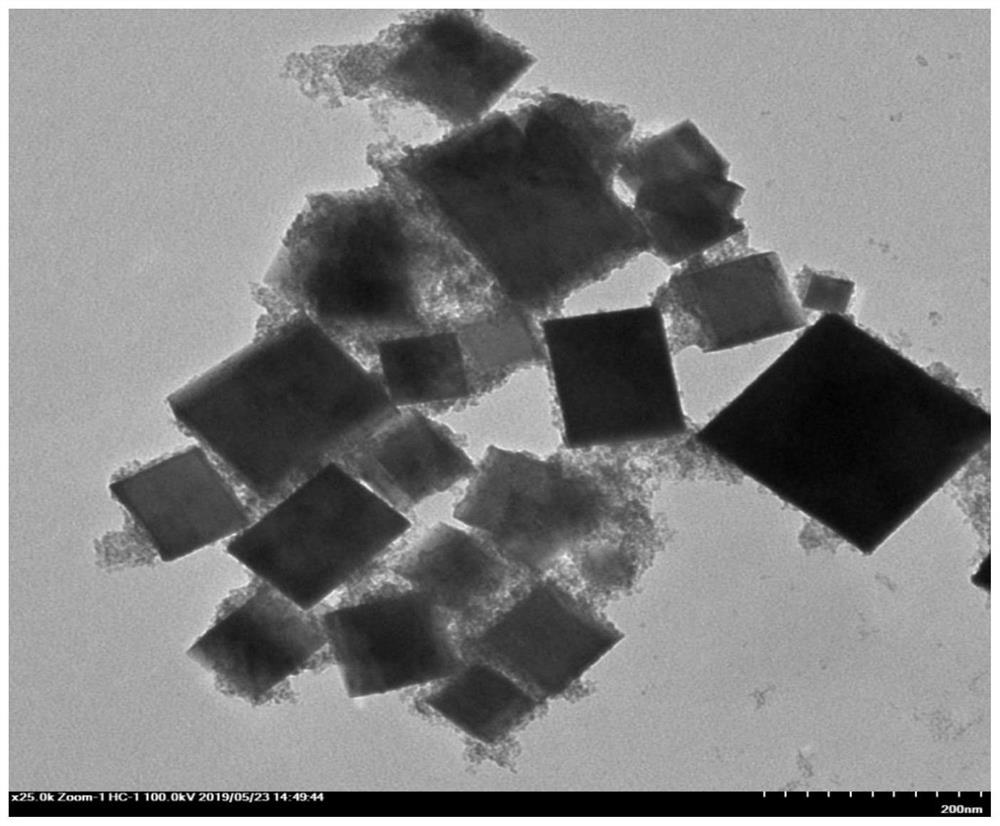

A technology of zinc metastannate and quantum dots, which is applied in the field of preparation of zinc metastannate quantum dots, can solve the problems of large particle size of reaction products, low catalytic efficiency, high toxicity of raw materials, etc., and achieve accelerated drying rate, large specific surface area, Effect of Catalytic Efficiency Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of zinc metastannate quantum dots, characterized in that the preparation method comprises the following steps:

[0033] (1) Weigh 0.03-0.045g of zinc oxide, put it into a 100ml beaker, add 30ml of distilled water, and place it on a magnetic stirrer to keep stirring until it is completely dissolved to form the first solution;

[0034] (2) slowly adding potassium stannate and urea to the above-mentioned first solution according to a certain proportion to form a second solution, wherein the mass ratio of each component is zinc oxide: potassium stannate: urea is 3-5:10-15 :40-60;

[0035] (3) Put the above-mentioned second solution in a magnetic stirrer and stir at 200-500r / min for 30-40min to obtain a suspension, transfer the suspension to an autoclave, and then place it in an electrothermal constant temperature at 150-200°C The reaction was carried out in a blast drying oven for 6-8h, then taken out and cooled to room temperature, and a white precipi...

Embodiment 1

[0038] A preparation method of zinc metastannate quantum dots, characterized in that the preparation method comprises the following steps:

[0039] (1) Weigh 0.04g of zinc oxide, put it into a 100ml beaker, add 30ml of distilled water, and keep stirring on a magnetic stirrer until it is completely dissolved to form the first solution;

[0040] (2) slowly adding potassium stannate and urea to the above-mentioned first solution according to a certain proportion to form a second solution, wherein the mass ratio of each component is zinc oxide: potassium stannate: urea is 4:13:50;

[0041](3) The above-mentioned second solution was placed in a magnetic stirrer and stirred at 500 r / min for 35 min to obtain a suspension, the suspension was transferred to a high-pressure reactor, and then placed in a 150 ℃ electric heating constant temperature blast drying oven to react 7h, then take out and cool to room temperature, and obtain a white precipitate after filtration;

[0042] (4) The ...

Embodiment 2

[0046] A preparation method of zinc metastannate quantum dots, characterized in that the preparation method comprises the following steps:

[0047] (1) Weigh 0.045g of zinc oxide, put it into a 100ml beaker, add 30ml of distilled water, and place it on a magnetic stirrer to keep stirring until it is completely dissolved to form the first solution;

[0048] (2) slowly adding potassium stannate and urea to the above-mentioned first solution according to a certain proportion to form a second solution, wherein the mass ratio of each component is zinc oxide: potassium stannate: urea is 3:15:40;

[0049] (3) The above-mentioned second solution was placed in a magnetic stirrer and stirred at 200 r / min for 40 min to obtain a suspension, the suspension was transferred to a high-pressure reactor, and then placed in a 200 ℃ electric heating constant temperature blast drying oven to react 8h, then take out and cool to room temperature, and obtain a white precipitate after filtration;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com