Bubble-breaking screen frame

A mesh frame and bubble breaking technology is applied in the field of oil fume filtering devices, which can solve problems such as polluting the atmosphere and achieve the effect of reducing liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

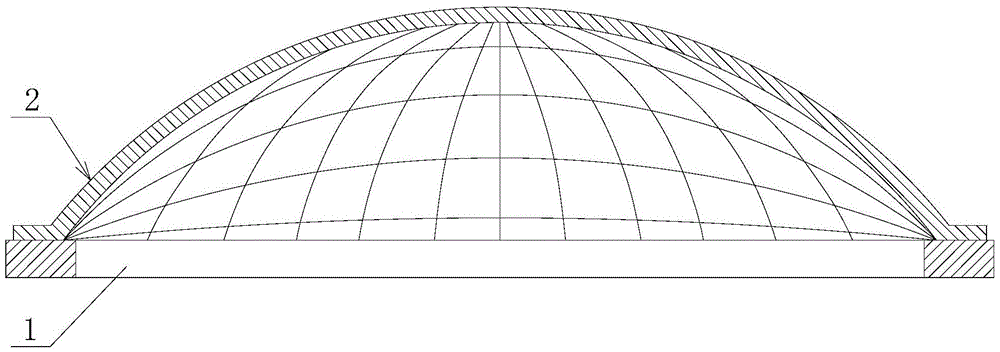

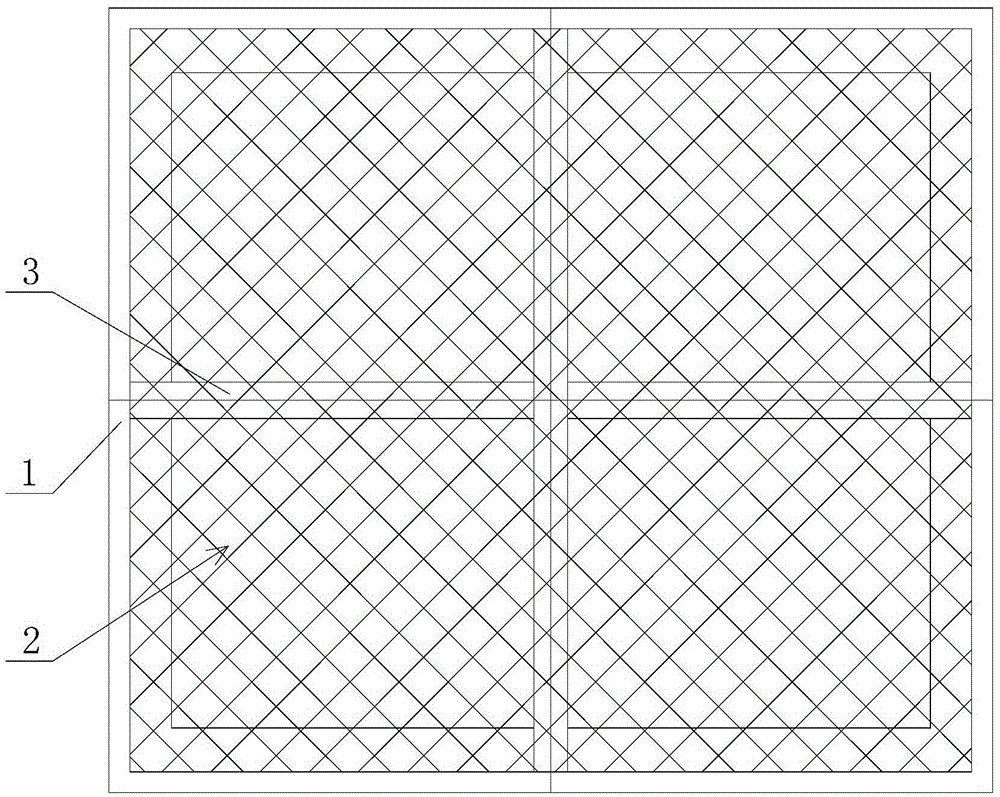

[0017] Such as Figure 1 to Figure 4 As shown, a kind of bubble-breaking screen frame includes the outermost ring frame 1 and the mesh structure 2 covering the hollow area in the middle of the ring frame 1, the surrounding of the mesh structure 2 is connected with the ring frame 1, and the mesh The structure arches towards one side of the ring frame 1 . When the detergent foam meets the network structure 2 and ruptures, a small part of the liquid remaining on the network structure 2 flows down along the arched network structure 2 to reduce the residual liquid on the network structure 2 and prevent Detergent bubbles are generated again due to the formation of a detergent film on the network structure 2 .

[0018] The ring frame 1 is provided with two arched flat belts 3 perpendicularly intersecting each other. The two arched flat belts 3 over...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com