Rapid detection method for cloth color difference quality under pretreatment

A detection method and quality technology, applied in textile testing, preparation of test samples, measurement of color/spectral characteristics, etc., can solve the problem of high cost of raw materials, achieve simple equipment, avoid waste of time efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Use the rapid detection method of the present invention to test the color difference of CVC16*CVC12*108*56*58 / 59 3 / 1S cloth under mercerizing.

[0033] The specific steps are:

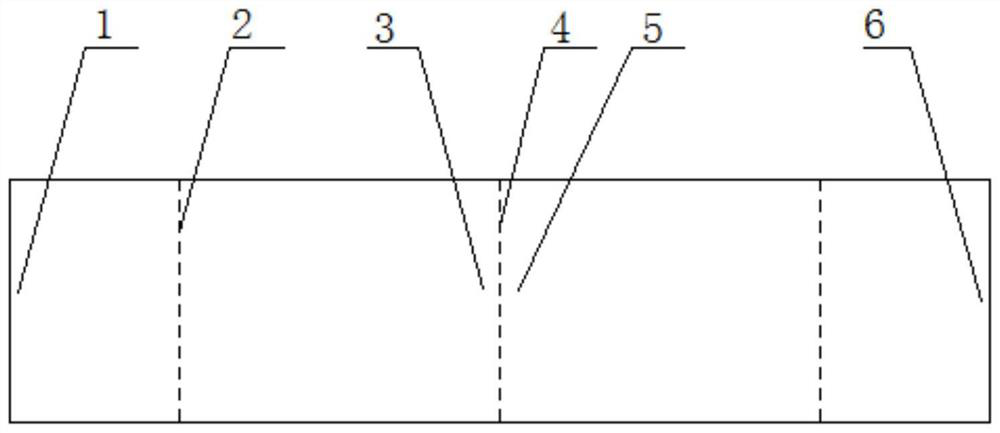

[0034] (1) Fabric preparation: Take a rectangular fabric to be tested with a width of 160 cm in the weft direction and a width of 20 cm in the warp direction, and sew the two long selvedges together to form a "tube shape" to obtain the sample fabric;

[0035] (2) Preparation of dye auxiliaries: Take 500mL of hot water at 60°C and add 24g of dye to stir and dissolve to obtain a dye liquor; take 5000mL of hot water at 60°C and add 700g of sodium sulfate to obtain a solution of sodium sulfate; take 1000mL of hot water at 60°C Add 350g of soda ash and stir to dissolve to obtain soda lye;

[0036] (3) Simulated dip-dyeing: Put the sample fabric into a fully automatic washing machine (EG80128X58GUI), set the "washing + dehydration" program, add 1.5L of 60°C water, start the washing program of the was...

Embodiment 2

[0066] Use the rapid detection method of the present invention to test the color difference of CM80 / 2*CM80 / 2T*160*69*62 / 63CP cloth under mercerizing.

[0067] The specific steps are:

[0068] (1) Fabric preparation: Take a rectangular fabric to be tested with a width of 160 cm in the weft direction and a width of 20 cm in the warp direction, and sew the two long selvedges together to form a "tube shape" to obtain the sample fabric;

[0069] (2) Preparation of dye auxiliaries: Take 500mL of hot water at 60°C and add 24g of dye to stir and dissolve to obtain a dye liquor; take 5000mL of hot water at 60°C and add 700g of sodium sulfate to obtain a solution of sodium sulfate; take 1000mL of hot water at 60°C Add 350g of soda ash and stir to dissolve to obtain soda lye;

[0070] (3) Simulated dip-dyeing: Put the sample fabric into a fully automatic washing machine (EG80128X58GUI), set the "washing + dehydration" program, add 1.5L of 60°C water, start the washing program of the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com