Ink viscosity self-adaptive ink-jet printing machine and self-adaptive method thereof

A self-adaptive, printer technology, applied in printing and other directions, can solve the problems of increasing the failure points of inkjet printers, poor working stability, and high failure rate, so as to reduce the volume of equipment and failure points, reduce the failure rate, and realize the damping effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention and invention are further described below in conjunction with accompanying drawing.

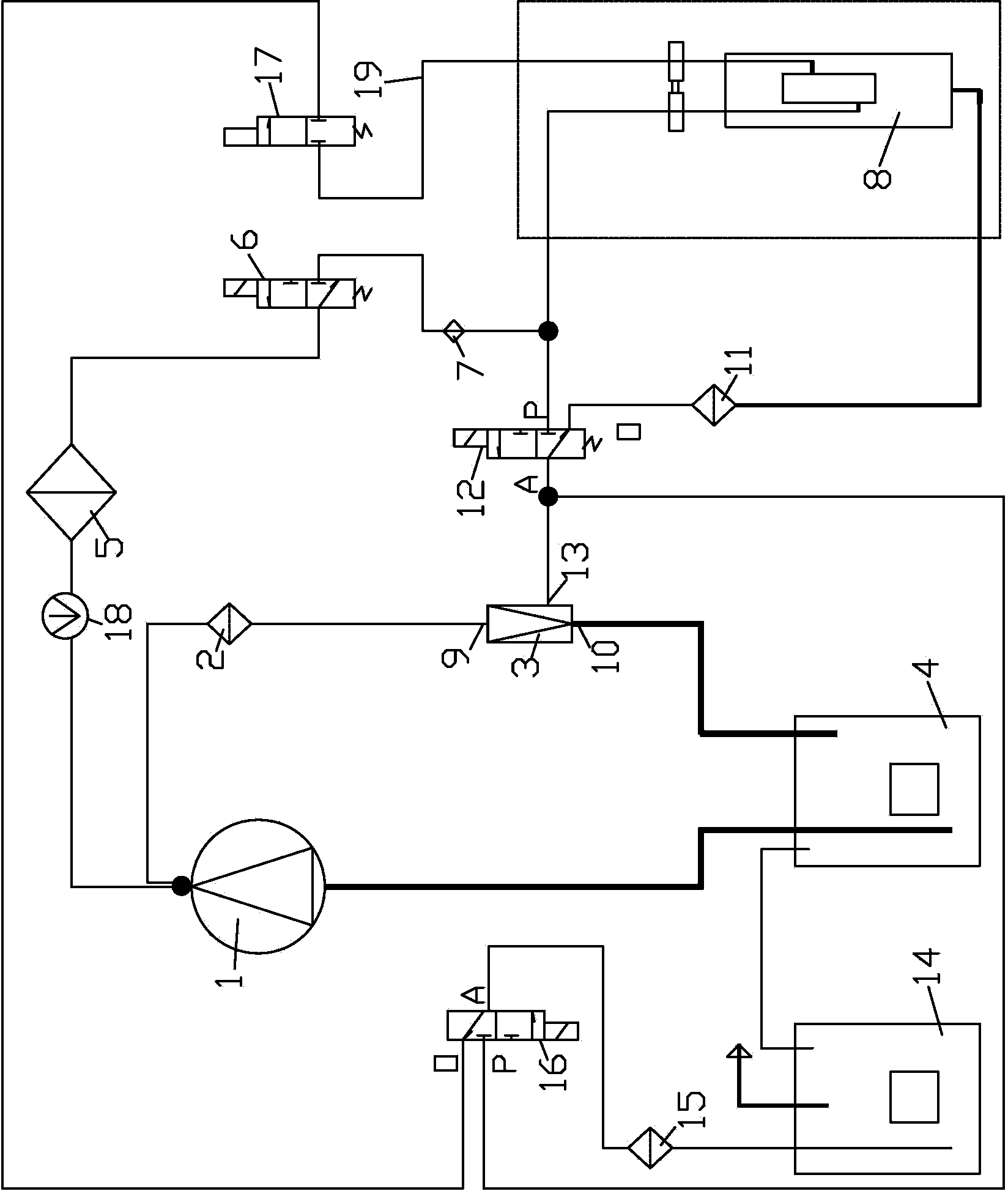

[0014] In the inkjet inkjet printer with ink viscosity self-adaption and its self-adaptive method involved in the present invention, the quantitative pump 1 in the power source distributes the ink to the nozzle 8 and the vacuum generator 3 respectively under the action of constant flow, and enters into the vacuum generator The ink of the device 3 flows back into the ink tank 4 through the damping hole, and at the same time, the vacuum generator 3 generates negative pressure to recycle the ink that does not participate in the printing information in the nozzle 8 to the ink tank 4. When the viscosity of the ink increases, the ink flowing through the damping hole The backflow slows down, the ink supply pressure at the outlet of the quantitative pump 1 and the nozzle 8 increases, and the return flow through the damping hole accelerates when the viscosity of the ink dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com