Engine stator stable connection structure and method

A connection structure and engine technology, applied in the direction of engine components, machines/engines, stators, etc., can solve the problems of large interference, low stability of stator connection structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

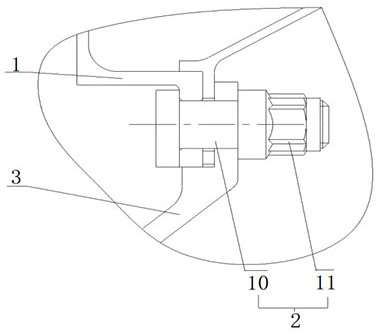

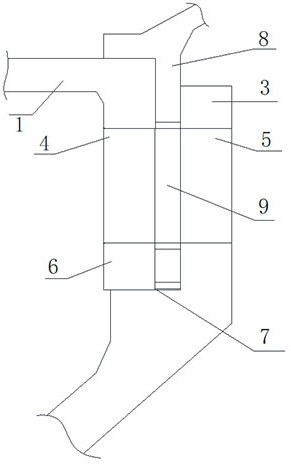

[0031] As a specific embodiment, it also includes a method for stabilizing the connection of the engine stator, first positioning the stop protrusion 6 on the first stator casing 1 and the stop groove 7 on the second stator casing 3 , the first bolt hole 4 on the first stator casing 1 and the bolt hole on the second stator casing 3 are coaxial, and then screw the screw 10 part of the precision bolt 2 into the first bolt hole 4 and the second bolt In the hole 5, finally screw in the nut 11 to fit closely with the second stator casing 3 to complete the installation.

[0032] By adopting the method of notch positioning first and then screw hole processing, high-precision machining and high coaxiality of the first bolt hole 4 and the second bolt hole 5 can be achieved, and the precision bolt 2 installed in this way can be aligned with the first stator machine. The stable cooperation between the casing 1 and the second stator casing 3 ensures the continuity and stable operation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com