A continuous double-roll die punching device for circuit boards

A circuit board and roller type technology is applied in the field of continuous-to-roll die punching and forming devices for ultra-long circuit boards. Achieve the effect of continuous work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

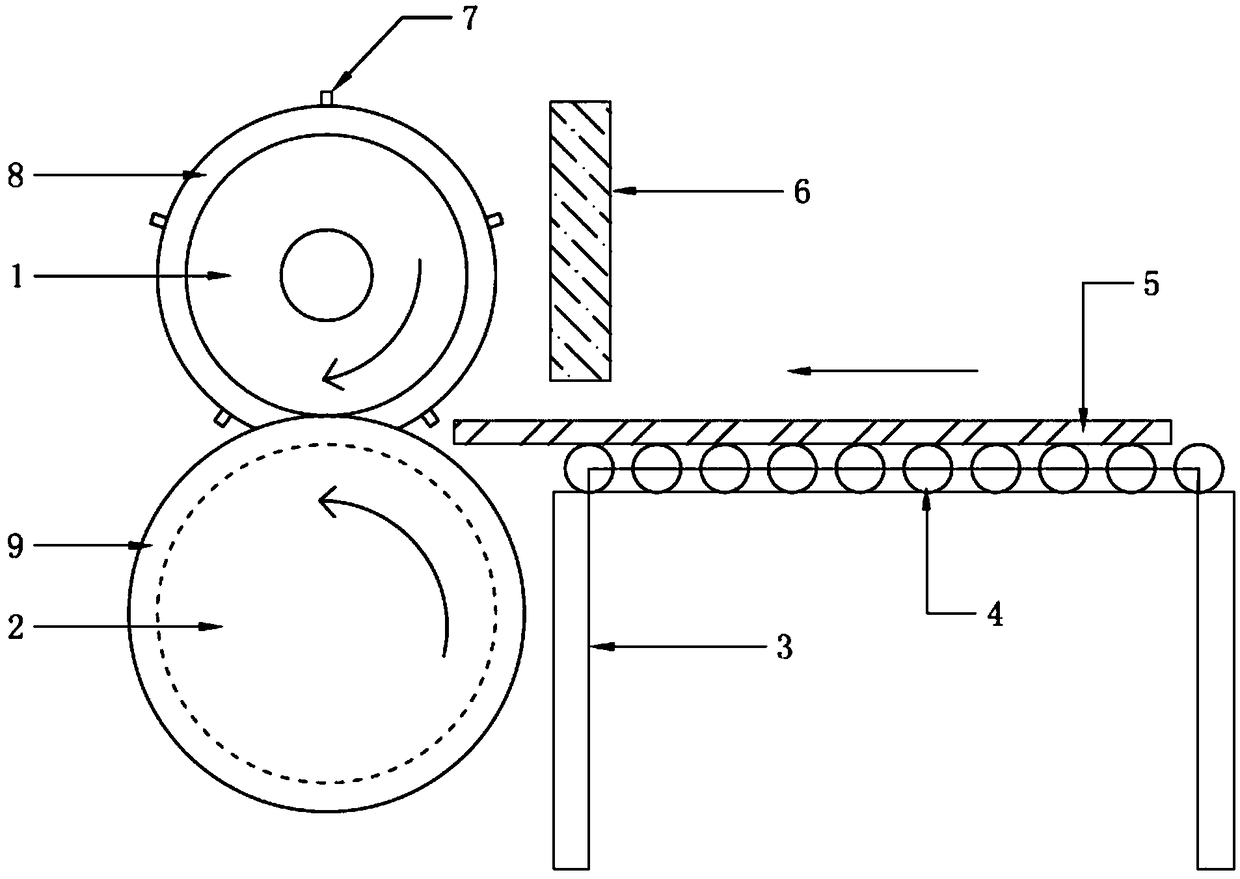

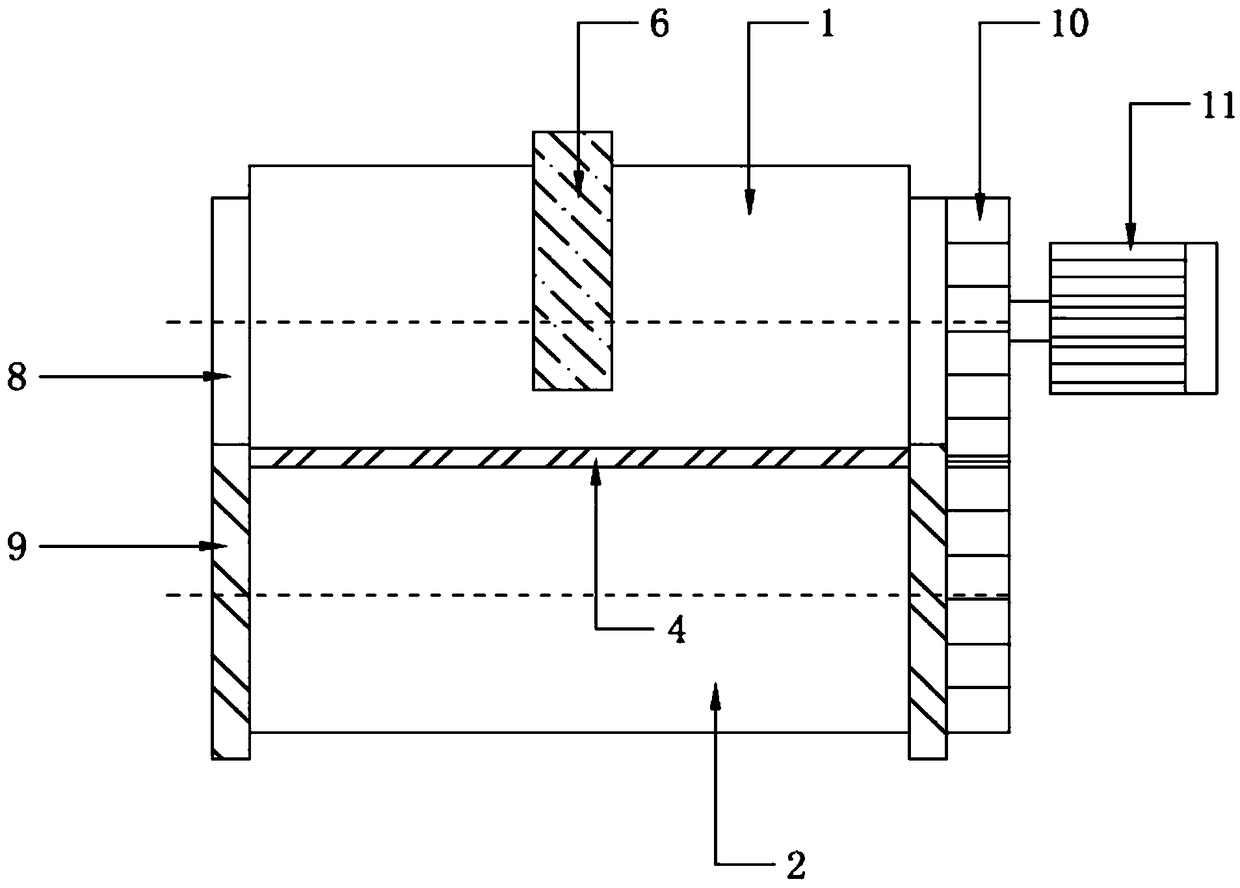

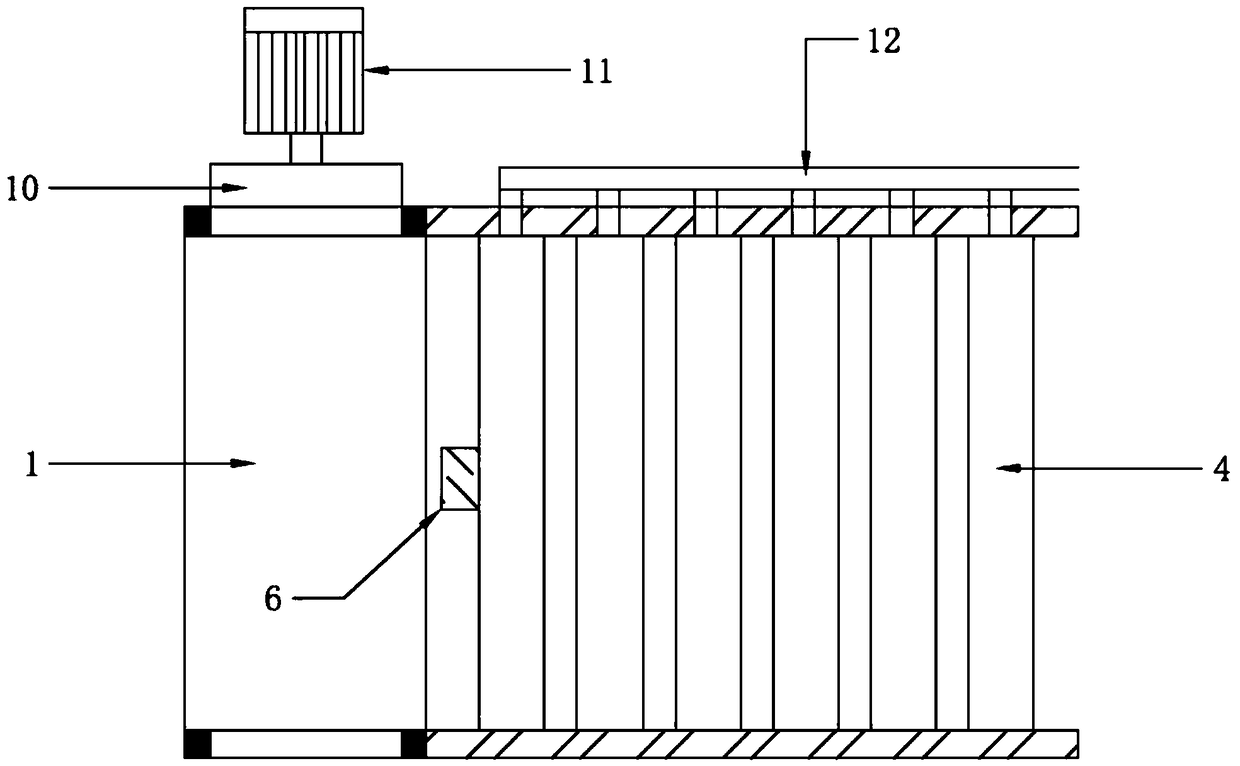

[0019] A continuous pair-roller die punching and forming device for a circuit board includes an upper roller body 1 and a lower roller body 2. A mold (not shown), the upper roller body 1 and the lower roller body 2 are provided with a row of feeding rollers 4 on the side of the plane where the upper roller body 1 and the lower roller body 2 are engaged. The feeding rollers 4 are arranged on the feeding work frame 3 and pass through a conveyor belt. 12 Uniformly connected to a conveying motor (not shown), the feeding work frame 3 is provided with a sensor 6 above one end near the upper roller body 1, and the sensor 6 is connected to a PLC (not shown), and the PLC is connected to control a pair of The roller motor 11 and the counter-roller motor 11 are connected to the upper roller body 1, and the upper roller body 1 and the lower roller body 2 are interlocked and connected with each other through a transmission gear 10.

[0020] The lower roller body 2 has an internal hollow struc...

Embodiment 2

[0022] A circuit board continuous pair-roll type punching and forming device, comprising an upper roller body 1 and a lower roller body 2. The upper roller body 1 is provided with a convex mold 7, and the lower roller body 2 is provided with a concave corresponding to the convex mold 7. A mold (not shown), the upper roller body 1 and the lower roller body 2 are provided with a row of feeding rollers 4 on the side of the plane where the upper roller body 1 and the lower roller body 2 are engaged. The feeding rollers 4 are arranged on the feeding work frame 3 and pass through a conveyor belt. 12 Uniformly connected to a conveying motor (not shown), the feeding work frame 3 is provided with a sensor 6 above one end near the upper roller body 1, and the sensor 6 is connected to a PLC (not shown), and the PLC is connected to control a pair of The roller motor 11 and the counter-roller motor 11 are connected to the upper roller body 1, and the upper roller body 1 and the lower roller ...

Embodiment 3

[0025] The difference between this embodiment and the first embodiment is that a single-chip microcomputer is used instead of a PLC to receive signals from the sensor 6 and issue simple commands to control the roller motor 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com